Speed reducer assembly and vehicle provided with same

A reducer and assembly technology, which is applied in the vehicle reducer assembly and the vehicle field with the reducer assembly, can solve the problems that the loss of spline meshing force transmission energy cannot be eliminated, and the cost of the motor and rear axle is high. Achieve the effect of reducing power transmission path, reducing unsprung mass and increasing transmission efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

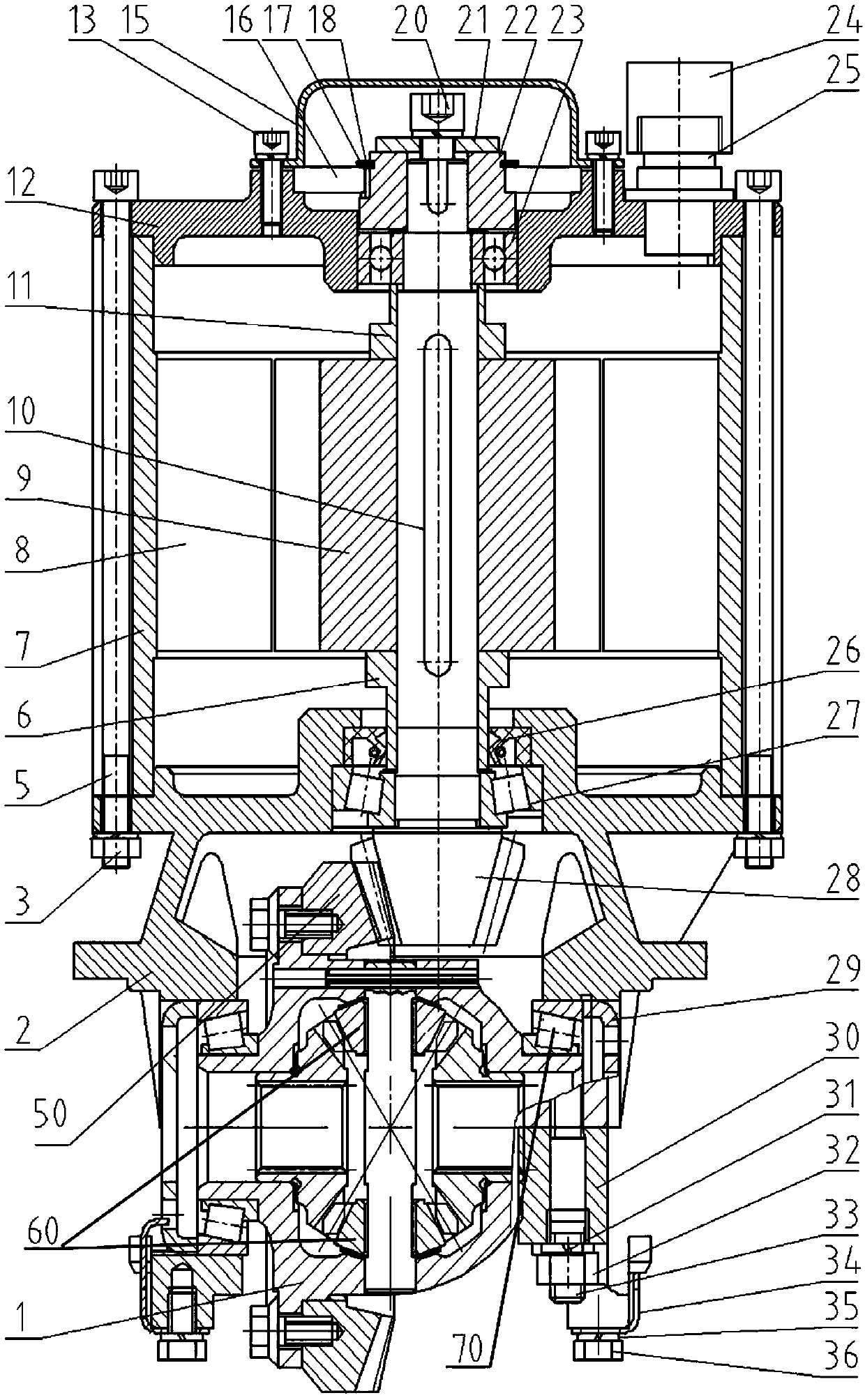

[0031] Such as figure 1 Shown is a schematic structural diagram of the reducer assembly in Embodiment 1 of the present invention. Embodiment 1 of the present invention provides a reducer assembly, which includes a motor assembly, a differential assembly 1 and a driving wheel shaft 10, the motor assembly is connected to the differential assembly 1 through the driving wheel shaft 10, and sends into 1 drive. The motor assembly is connected with the driving wheel shaft 10, and the motor assembly drives the driving wheel shaft 10 to rotate.

[0032] One end of the driving wheel shaft 10 is provided with a driving gear 28 , the driving gear 28 meshes with the driven gear 50 in the differential assembly 1 , and the driving gear 28 is used to transmit to the driven gear 50 in the differential assembly 1 . Preferably the drive gear 28 is a bevel gear. Preferably, the axis of the driving wheel shaft 10 coincides with the axis of the motor assembly.

[0033] The motor assembly includ...

Embodiment 2

[0045] The difference between this embodiment and Embodiment 1 is that an adjustment device is also provided on the differential assembly 1, and the adjustment device can drive the differential body to move axially and laterally to adjust the gears of the driving gear 28 and the driven gear 50 Fit clearance. The adjusting device is preferably an adjusting screw.

Embodiment 3

[0047] The difference between this embodiment and Embodiment 2 is that a differential bearing 70 is also arranged on the differential assembly 1, and the differential bearing 70 is arranged at both ends of the differential body, and the inside of the differential bearing 70 Circles can be used to traverse either the left or right half shaft. The axis of the differential bearing 70 is the same as the left half shaft or the right half shaft. The adjusting device is an adjusting screw ring 29 , and the adjusting screw ring 29 drives the differential body to move axially and laterally through the differential bearing 70 to adjust the gear fit clearance between the driving gear 28 and the driven gear 50 .

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com