Multi-station hydraulic and automatic foil-beating machine

A multi-station, hydraulic technology, applied in the direction of manufacturing tools, positioning devices, metal processing equipment, etc., can solve the problems of severe vibration, billet tearing, loud noise, etc., to improve production and processing efficiency, increase yield, and strike force big effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

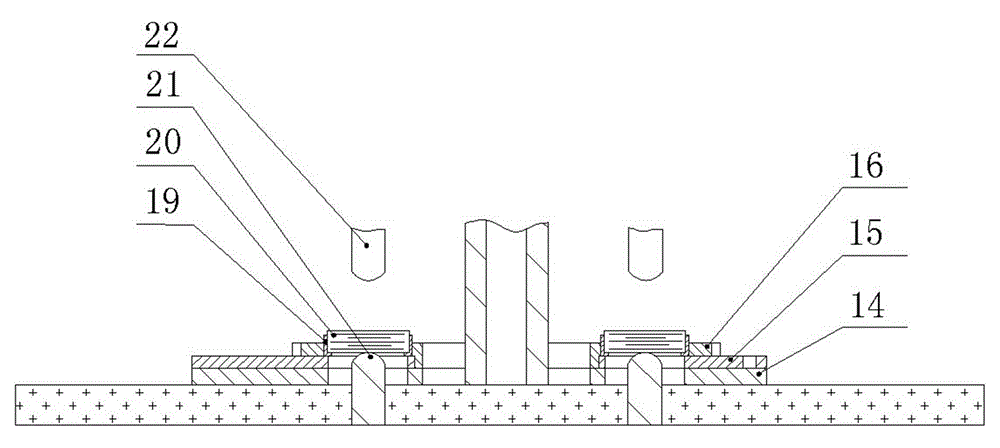

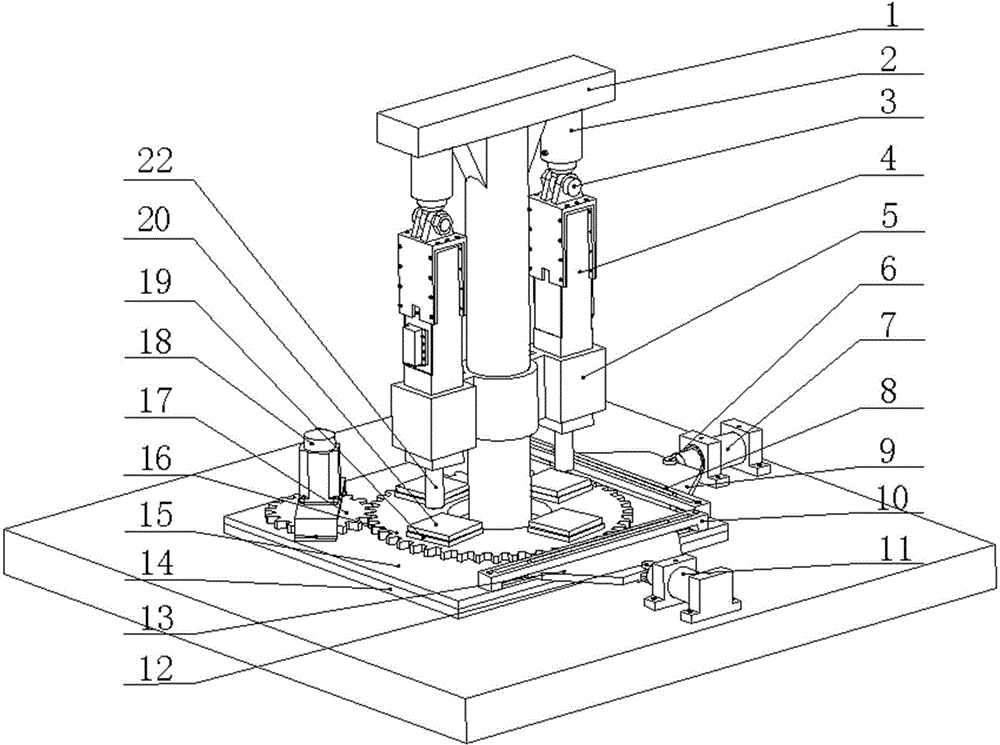

[0018] The technical scheme of the present invention will be further described below in conjunction with the accompanying drawings.

[0019] see figure 1 and figure 2 , The multi-station hydraulic automatic foiling machine includes a hammer head mechanism for reciprocating linear motion and a feeding mechanism for plane motion. The hammer head mechanism mainly includes the bracket (1), the lifting hydraulic cylinder (2), the hydraulic impact hammer (4) and the hammer rod (22); the feeding and feeding mechanism mainly includes the mobile table (15), the horizontal feeding mechanism and To the mechanism, the mobile table (15) is driven by the horizontal feed mechanism and the longitudinal feed mechanism, the rotary table (16) is placed on the mobile table (15), and the motor (18) installed on the mobile table (15) ) through the rotation of the rotary table (16) driven by the pinion (17). There is a square through hole on the rotary table (16), and there is a clamp (19) on the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com