Fully-automatic foil hammering machine

A fully automatic, machine-based technology, applied in feeding devices, manufacturing tools, positioning devices, etc., can solve the problems of inability to adjust, useless work, low foiling efficiency, etc., to improve production and processing efficiency, avoid safety hazards, improve The effect of yield

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

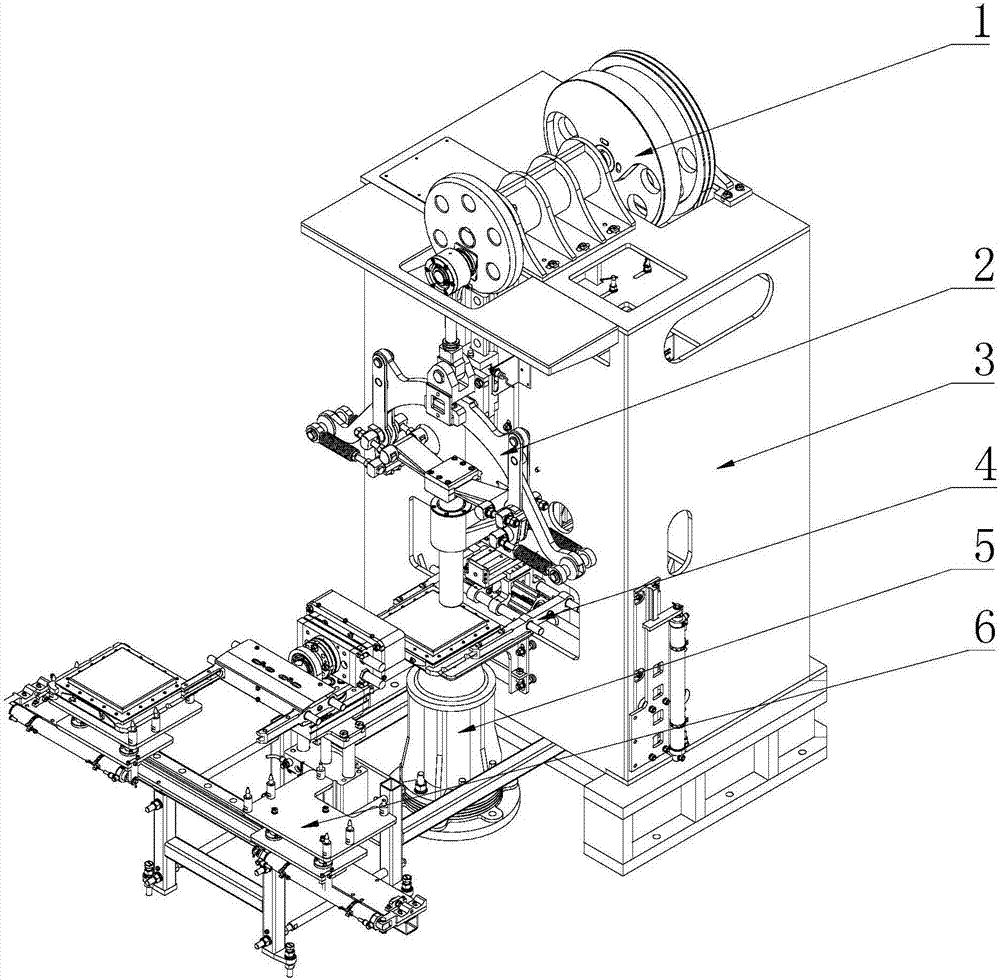

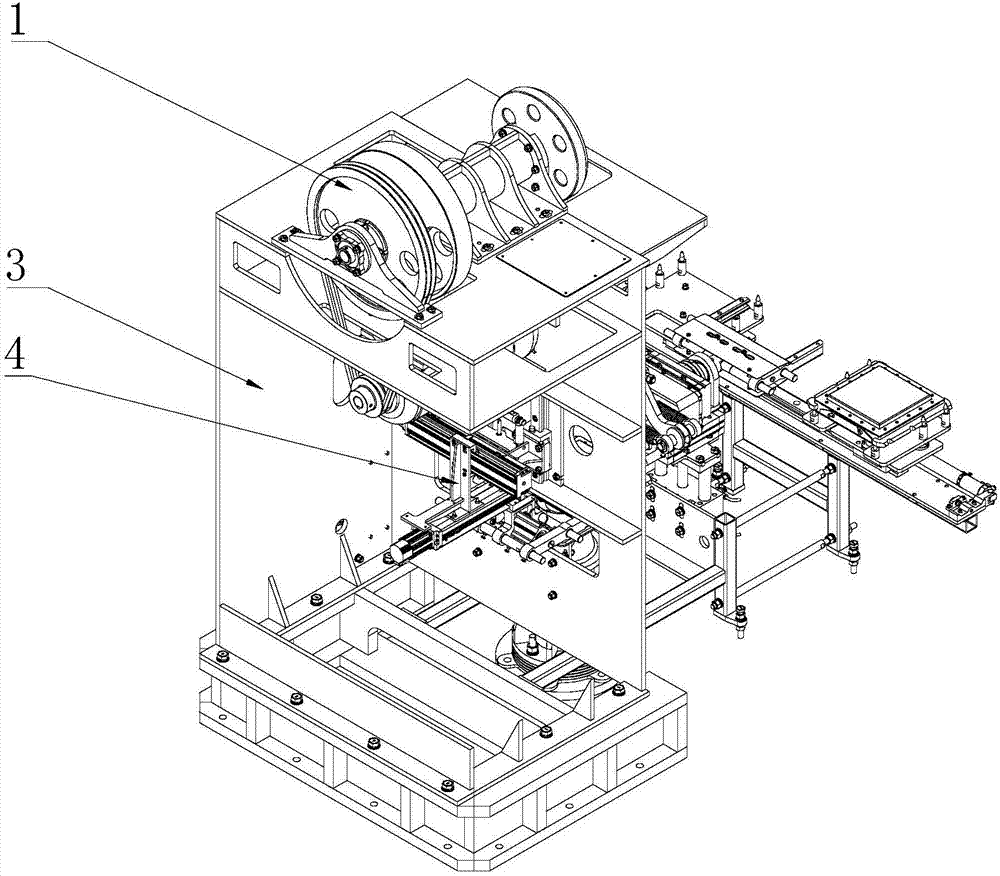

[0028] This embodiment is a fully automatic foiling machine with a structure such as Figure 1 to Figure 12 As shown, it includes a main body base 3, a hammering power part 1, a lever type vibratory hammer 2, a workpiece humanoid mobile table 4, a two-station feeding device 6, and an anvil 5; The power part drives the lever-type vibratory hammer to hammer up and down. The workpiece imitation moving table is installed in the main machine base, and the workpiece is moved on the hammer anvil by clamping and loading the hammer and hammered by the lever-type vibrating hammer. Two-station loading The device is installed on the outside of the main machine base, and the two-station loading device performs loading, unloading and flipping operations on the loaded workpiece;

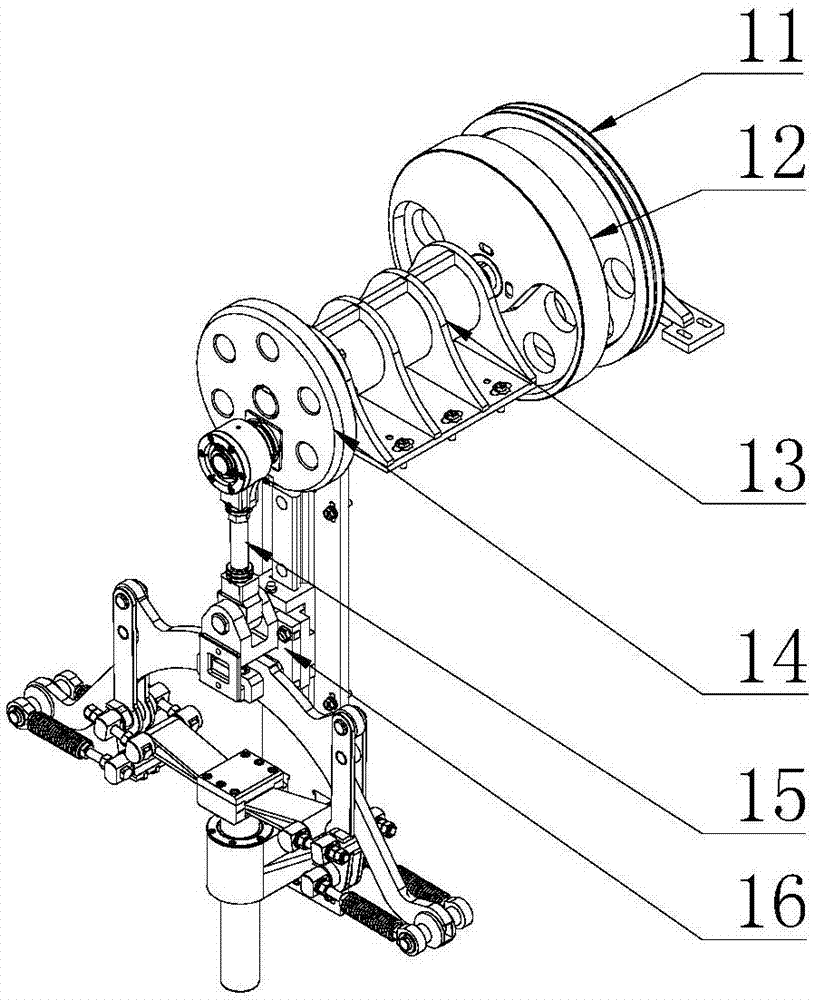

[0029] The hammering power part 1 includes a power source, a pulley 11, an inertia wheel 12, a main shaft seat 13, a crank wheel 14 and a slide rail kit 16. The power source is installed in the main frame, and the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com