Double-nozzle external heating type intermediate tank

A tundish and external heating technology, which is applied in metal processing equipment, casting molten material containers, casting equipment, etc., can solve the problems of heating the tundish and being unable to adapt to the electromagnetic induction with a large distance, so as to speed up the transformation and avoid space layout Retrofit and use with good effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

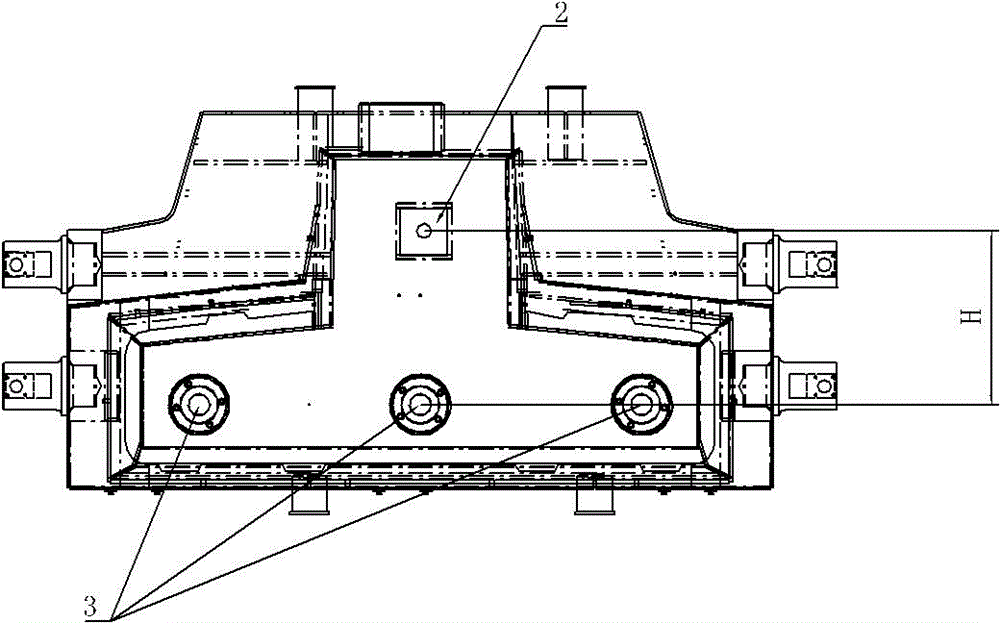

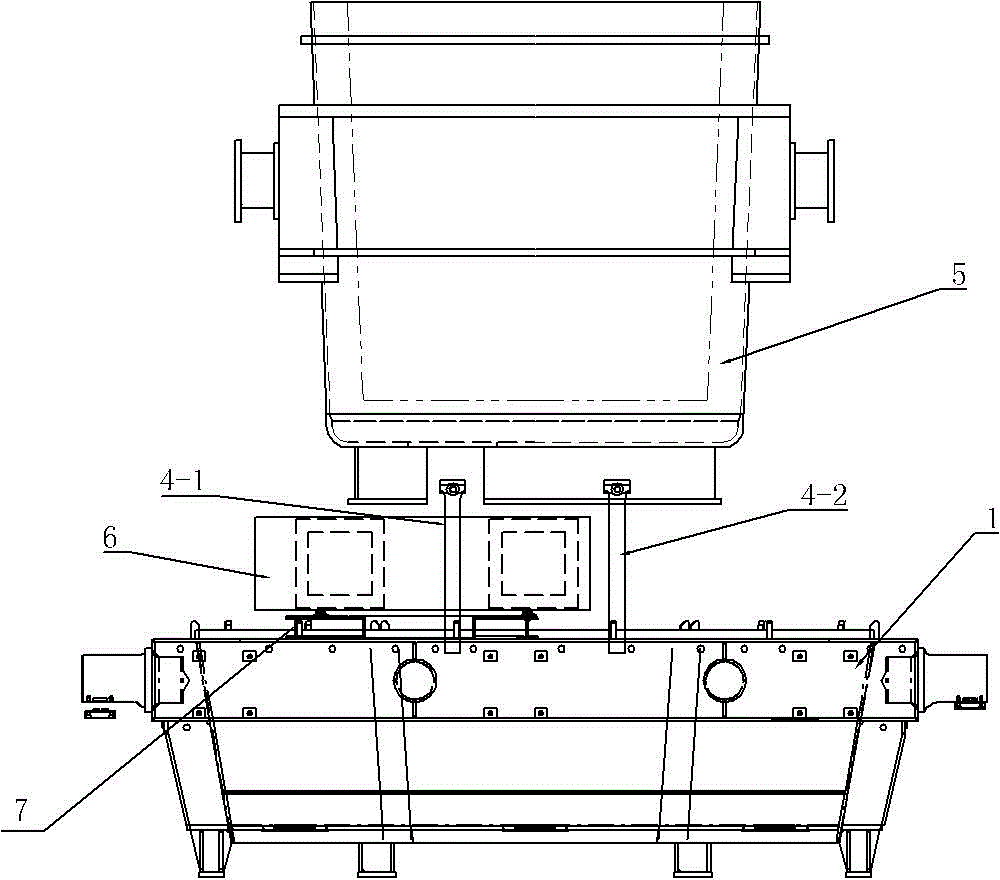

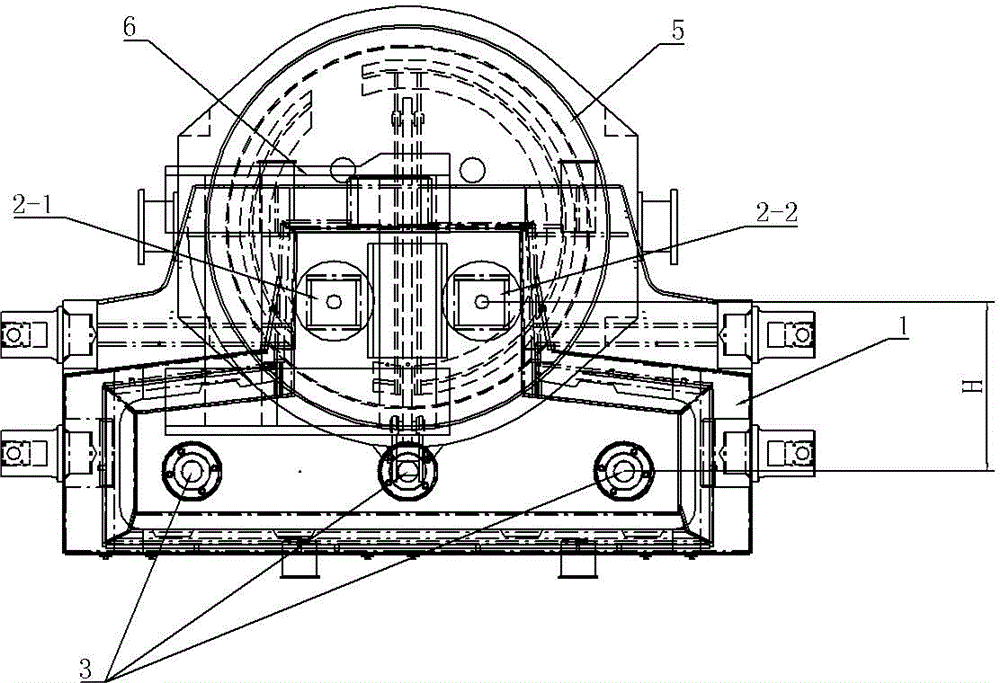

[0011] See figure 2 , image 3 and Figure 4 , the double nozzle external heating type tundish of the present invention, which comprises a tundish body 1, the tundish body 1 is provided with a molten steel tank pouring port and a tundish casting port 3, the lower part of the tundish casting port 3 is externally connected to a crystallizer, wherein the molten steel tank pouring There are two nozzles, which are the pouring port 2-1 of the molten steel tank and the pouring port 2-2 of the molten steel tank respectively. The double sliding nozzles of the tank 5 are connected, an electromagnetic induction heating device 6 is installed between the molten steel tank 5 and the tundish body 1, and the electromagnetic induction heating device 6 is installed around the outer periphery of the long nozzle 4-1, so that the electromagnetic induction heating device can The molten steel in the shroud 4-1 is heated by induction; the electromagnetic induction heating device 6 is installed on ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com