Engine valve lock clamp disassembling tool and method

A technology of engine valves and valve lock clips, which is applied in the field of tooling fixtures, can solve problems such as unreasonable operation steps, unreasonable disassembly and installation of valve lock clips, and difficult to detect scratches, so as to avoid scratches and make disassembly and installation simple Reliable, long-life effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] The present invention is described in conjunction with accompanying drawing and specific embodiment:

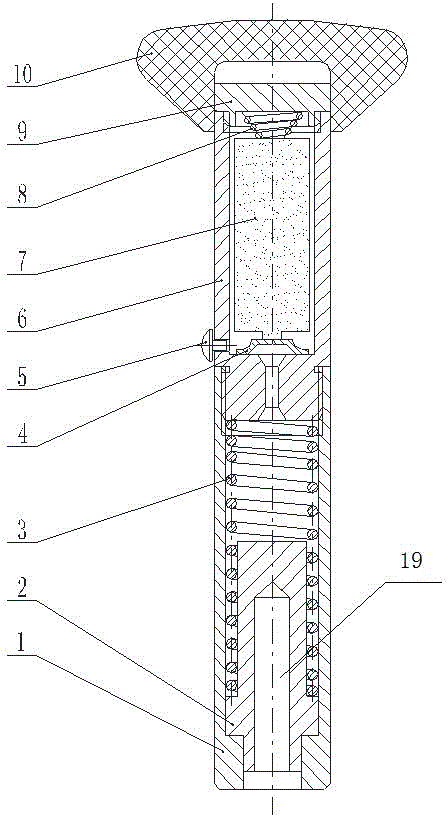

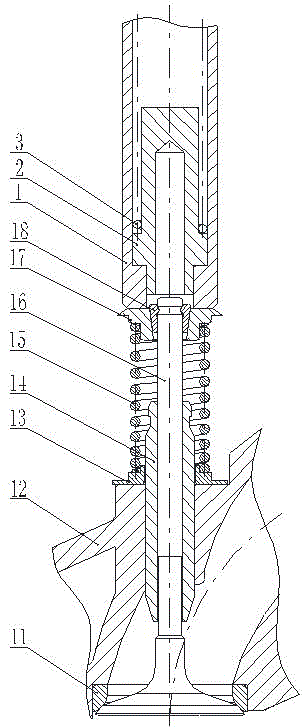

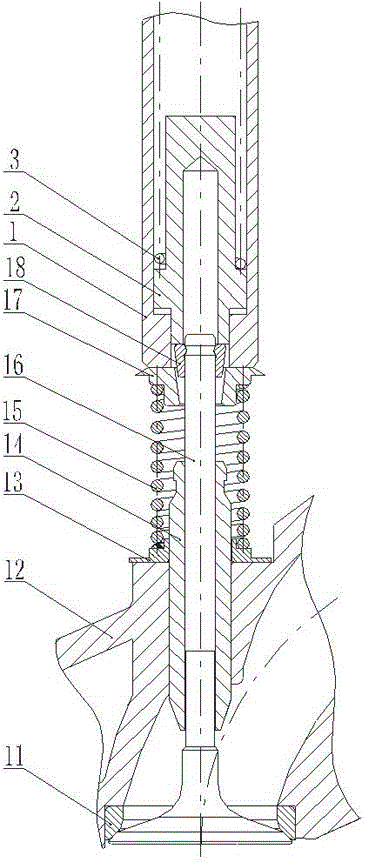

[0020] like figure 1Shown, a kind of engine valve lock clip dismounting tool, described dismounting tool includes valve spring seat pressure head 1, valve lock clamp pressure head 2 and handle 10; Described valve spring seat ring pressure head 1 center A cylinder with a stepped through hole, and the stepped through hole in the center of the valve spring seat ring pressure head 1 is a structure with a large top and a small bottom; the valve lock clamp pressure head 2 is located at the valve spring seat ring pressure head 1 In the center through hole of the valve spring seat ring pressure head 1, and can slide up and down in the center through hole of the valve spring seat ring pressure head 1; the upper end of the valve lock pressure head 2 is sleeved with a lock clamp pressure to reset the valve lock pressure head Head spring 3; the air door lock clamping head 2 is an...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com