Pressurizing and tensioning stop gear of plastic bottle blowing machine

A technology of a limit mechanism and a blowing machine, which is applied in the field of plastic machinery, can solve the problems that cannot be completely eliminated, the mold volume is large, and the opening and closing mold clamping pressure is large.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

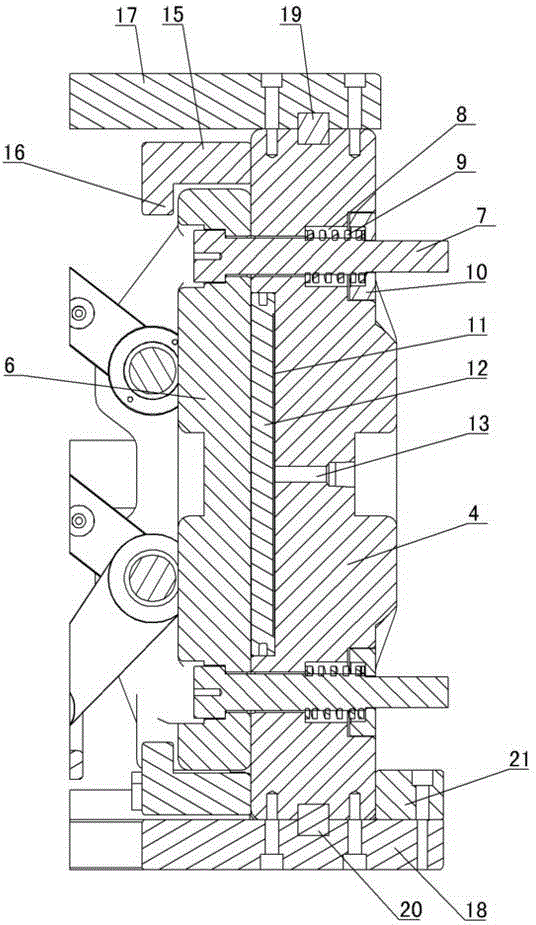

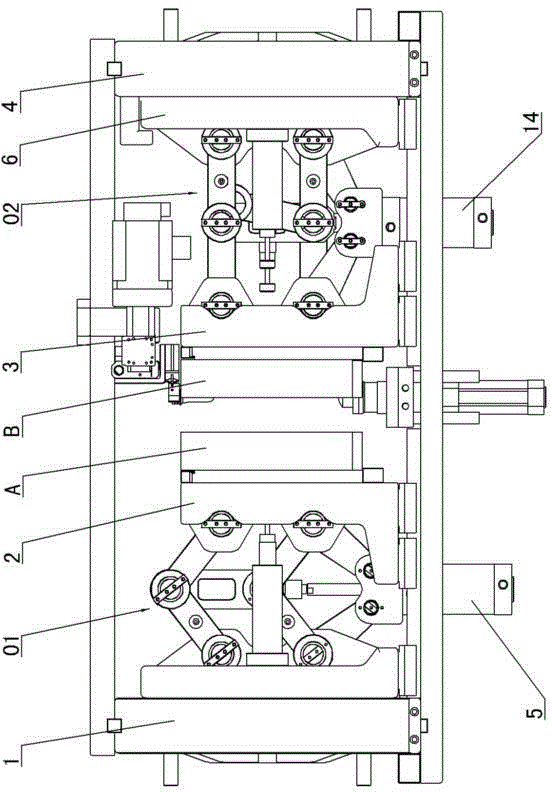

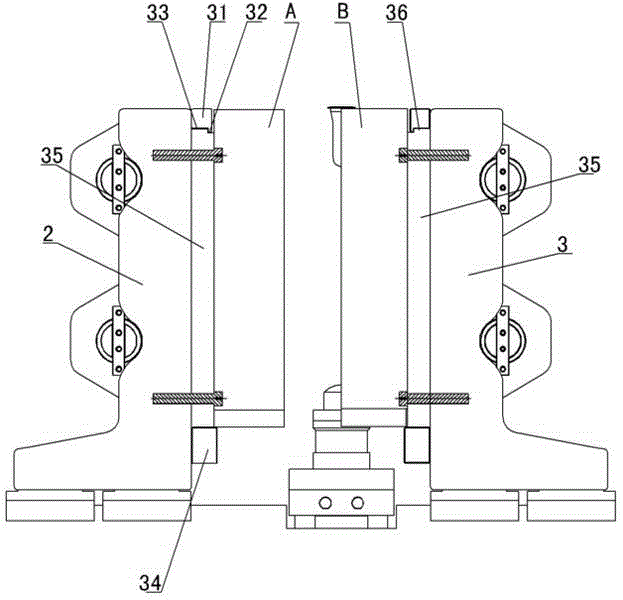

[0010] The invention relates to a pressurized and tensioned limit mechanism of a plastic bottle blowing machine, such as figure 1 — image 3 As shown, it includes a rear template 1, a movable template 2, a front template 3 and a fixed template 4 arranged on the frame of the bottle blowing machine. There is an opening and closing mechanism 01 between the template 1 and the moving template 2, and the opening and closing mechanism consists of Driven by mold clamping cylinder 5, there is mold clamping mechanism 02 between front template 3 and fixed template 4, mold clamping mechanism is driven by clamping cylinder 14, one half-half mold A is installed on moving template, and another one is installed on front template 3 Huff Die B. There are many specific technical solutions for the mold opening and closing mechanism and the mold locking mechanism, and the one that is widely used at present is the elbow type, which works just like the elbow arm of the human body. The main technic...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap