Preparation method of short range ordered cage type aminopropyl silsesquioxane spherical particles

A technology of silsesquioxane and aminopropyltrimethoxysilane, which is applied in the field of preparation of spherical aminopropylsilsesquioxane particles, can solve the problems of irregular morphology and structure of the product, and achieve a simple reaction system Ease of operation, high yield, and ease of large-scale production

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Example Embodiment

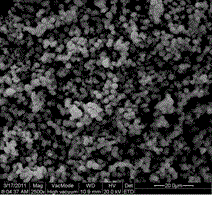

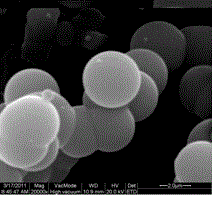

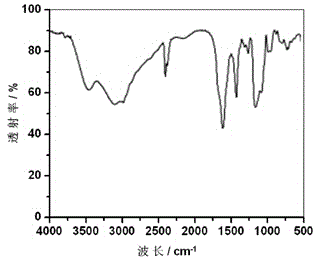

[0023] Example 1

[0024] 1. Dehydration treatment of tribenzoic acid

[0025] Put s-tribenzoic acid in an oven, heat and dehydrate at 80°C for 2h.

[0026] 2. Preparation of ethanol solution of γ-aminopropyltrimethoxysilane

[0027] Add 20mL of absolute ethanol into a 50mL three-necked flask, then measure 1mL of γ-aminopropyltrimethoxysilane into the flask, seal it, and stir with a stirrer at 180 rpm for 30-50min to obtain γ-aminopropyltrimethoxysilane ethanol solution of silane.

[0028] 3. Hydrolysis and condensation reaction

[0029] Weigh the m-tribenzoic acid prepared in step 1 and add it to the ethanol solution of gamma-aminopropyltrimethoxysilane prepared in step 2. The molar ratio of m-tribenzoic acid to gamma-aminopropyltrimethoxysilane is 1: 3. Stir for 30 minutes until the solids are completely dissolved. Then, 0.3 mL of ammonia solution with a pH of 10 was added, the stirring was continued for 10 min, and then the stirring was stopped. The reaction was left t...

Example Embodiment

[0032] Example 2

[0033] 1. Dehydration treatment of tribenzoic acid

[0034] Put s-tribenzoic acid in an oven, heat and dehydrate at 80°C for 2h.

[0035] 2. Preparation of ethanol solution of γ-aminopropyltrimethoxysilane

[0036] Add 20mL of absolute ethanol into a 50mL three-necked flask, then measure 1mL of γ-aminopropyltrimethoxysilane into the flask, seal it, and stir with a stirrer at 180 rpm for 30-50min to obtain γ-aminopropyltrimethoxysilane ethanol solution of silane.

[0037] 3. Hydrolysis and condensation reaction

[0038] Weigh the m-tribenzoic acid prepared in step 1 and add it to the ethanol solution of gamma-aminopropyltrimethoxysilane prepared in step 2. The molar ratio of m-tribenzoic acid to gamma-aminopropyltrimethoxysilane is 1: 1. Stir for 30 minutes until the solid is completely dissolved; then, add 0.3 mL of ammonia solution with a pH of 10, continue stirring for 10 minutes, stop stirring, let stand for 24 hours, and separate by centrifugation to...

Example Embodiment

[0041] Example 3

[0042] 1. Dehydration treatment of tribenzoic acid

[0043] Put s-tribenzoic acid in an oven, heat and dehydrate at 80°C for 2h.

[0044] 2. Preparation of ethanol solution of γ-aminopropyltrimethoxysilane

[0045] Add 20mL of absolute ethanol into a 50mL three-necked flask, then measure 1mL of γ-aminopropyltrimethoxysilane into the flask, seal it, and stir with a stirrer at 180 rpm for 30-50min to obtain γ-aminopropyltrimethoxysilane ethanol solution of silane.

[0046] 3. Hydrolysis and condensation reaction

[0047] Weigh the m-tribenzoic acid prepared in step 1 and add it to the ethanol solution of gamma-aminopropyltrimethoxysilane prepared in step 2. The molar ratio of m-tribenzoic acid to gamma-aminopropyltrimethoxysilane is 1: 2. Stir for 30 minutes until the solid is completely dissolved; then, add 0.3 mL of ammonia solution with a pH of 10, continue stirring for 10 minutes, stop stirring, let stand for 24 hours, and separate by centrifugation to...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap