Semi-hand shirt sewing method

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

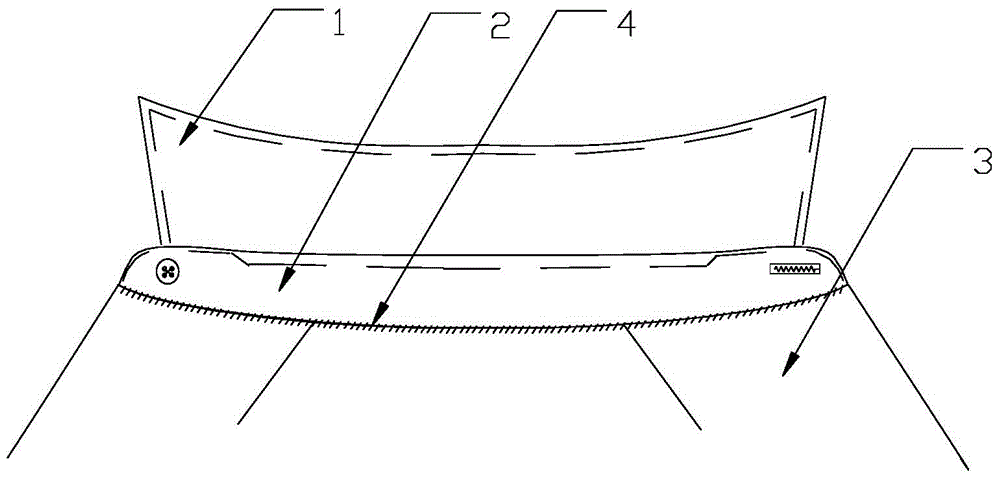

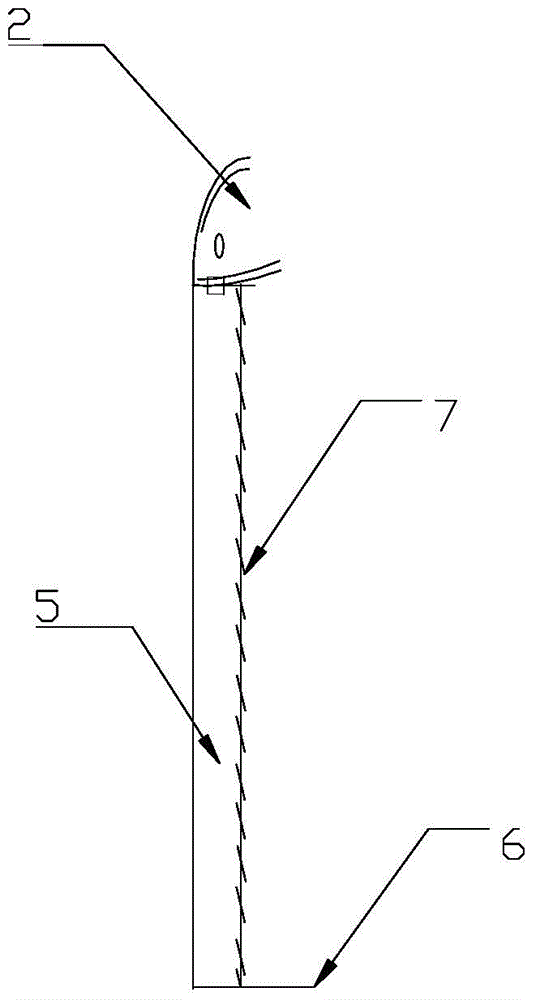

[0021] The present invention will be described in further detail below in conjunction with the accompanying drawings.

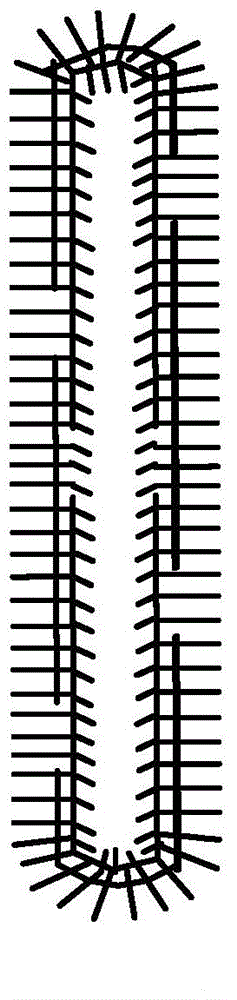

[0022] The invention discloses a semi-manual sewing method for a shirt. The method adopts a combination of manual processing and machine processing, wherein the processing of the front and rear parts of the shirt is processed by a machine, and the processing of the collar of the shirt, The processing of the right placket and the processing of the buttonholes are all hand-stitched. The method includes the following steps:

[0023] S1: Cut out the front, back, yoke, sleeves, cuffs and collar of the shirt, prepare the shirt button, which has four buttonholes, and put the front and back of the shirt together The side seams of the shirt are sewn by machine sewing, processed into a shirt body, and the yoke and the back shoulder of the shirt body are sewn together for spare use, and the sleeves and side seams are completed by machine sewing. And process the sleeve...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com