Continuous and automatic die-variable cutting device for fiber fabric

An automatic mold changing and cutting technology, applied in the cutting of textile materials, textiles and papermaking, etc., can solve problems such as low efficiency and complex operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

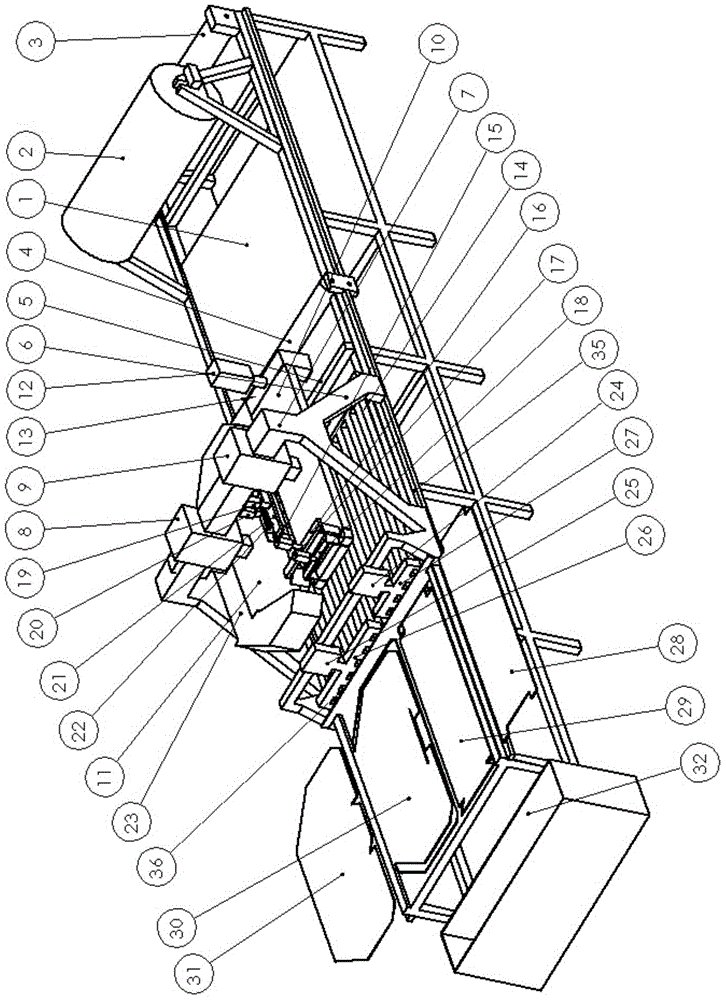

[0065] After long-term and in-depth research, the present inventor has provided a continuous automatic mold-changing cutting device for fiber cloth. The device can control the lifting mold platen to press the fiber cloth, and then select the switchable cutter group to realize continuous and automatic cutting of the fiber cloth. The cutting effect is good, and multiple cloths that meet the product requirements can be cut simultaneously. High cutting efficiency. Based on the above findings, the inventors have accomplished the present invention.

[0066] Fiber fabric continuous automatic die-changing cutting device

[0067] The invention provides a fiber cloth continuous automatic mode-changing cutting device, the device comprising:

[0068] A slidable mold frame assembly, the slidable mold frame assembly includes a slidable cutting mold frame 7 and one or more guide rails 35;

[0069] A mold platen assembly, the mold platen assembly comprising a first cylinder 8, a second cyl...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com