A heat grinder grinding device

A grinding device and thermal grinding machine technology, which is applied in the field of wood processing equipment, can solve the problems of the length of the cantilever at the front end of the main shaft, etc., and achieve the effects of simplifying the structure, reducing radial runout errors, and improving stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

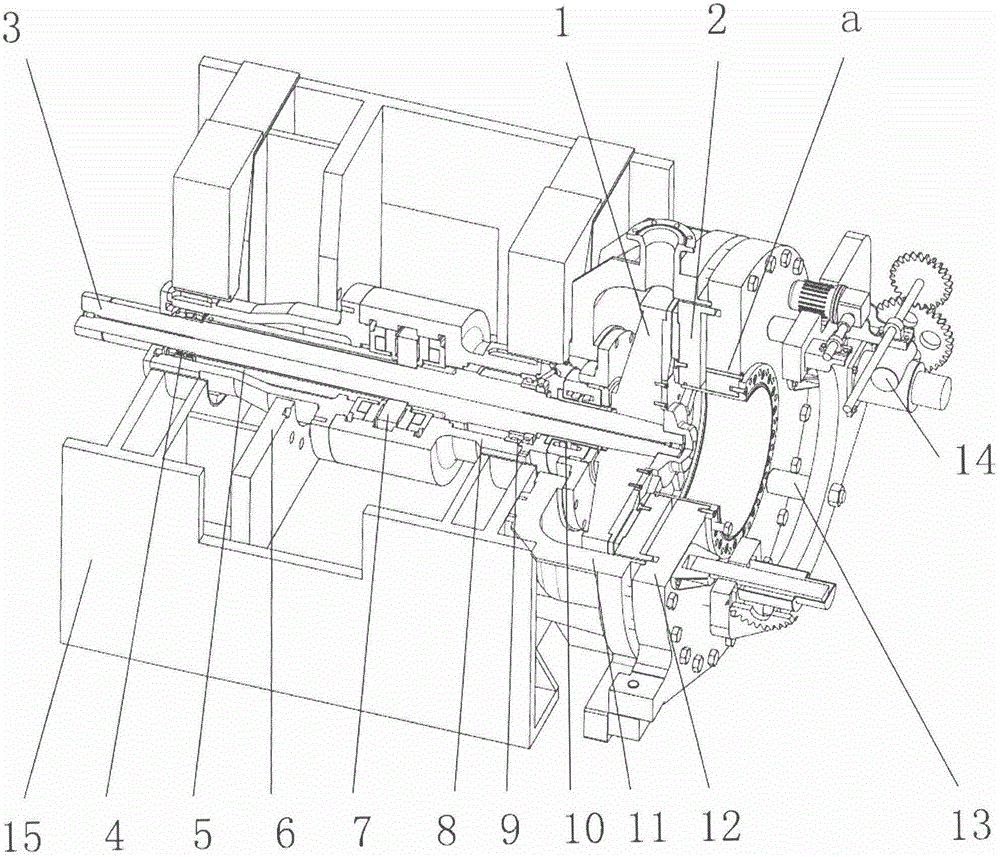

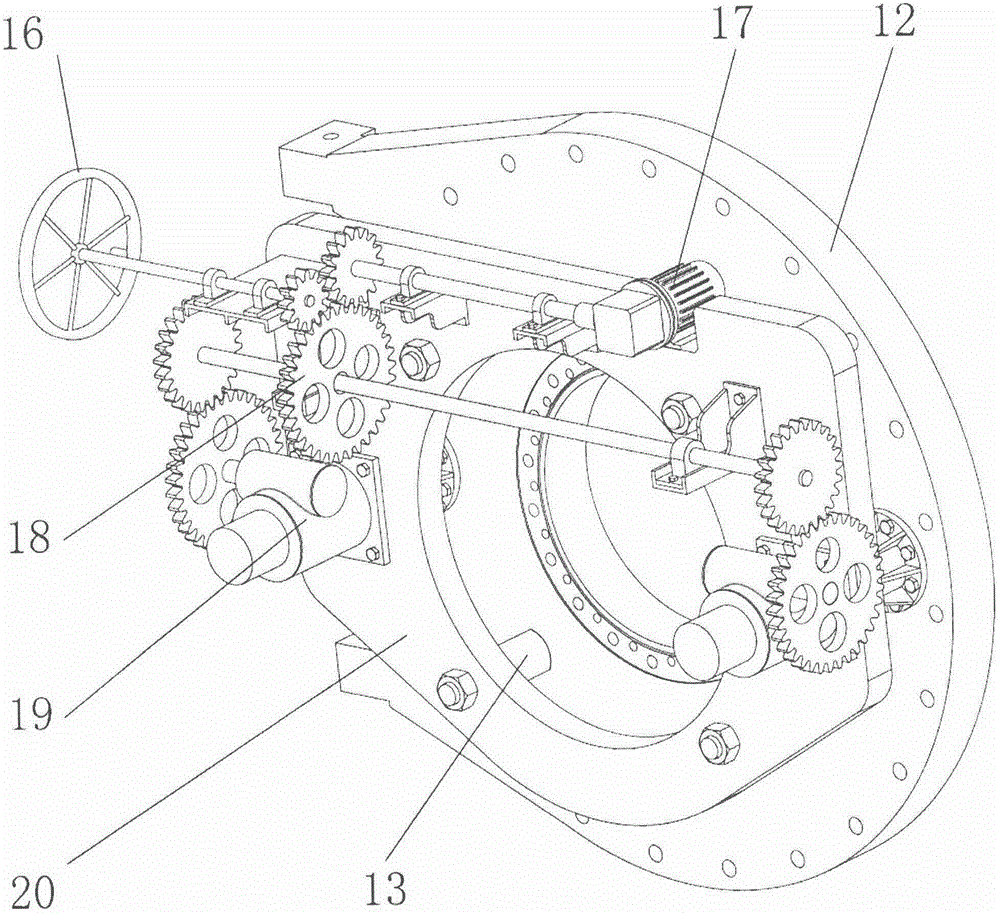

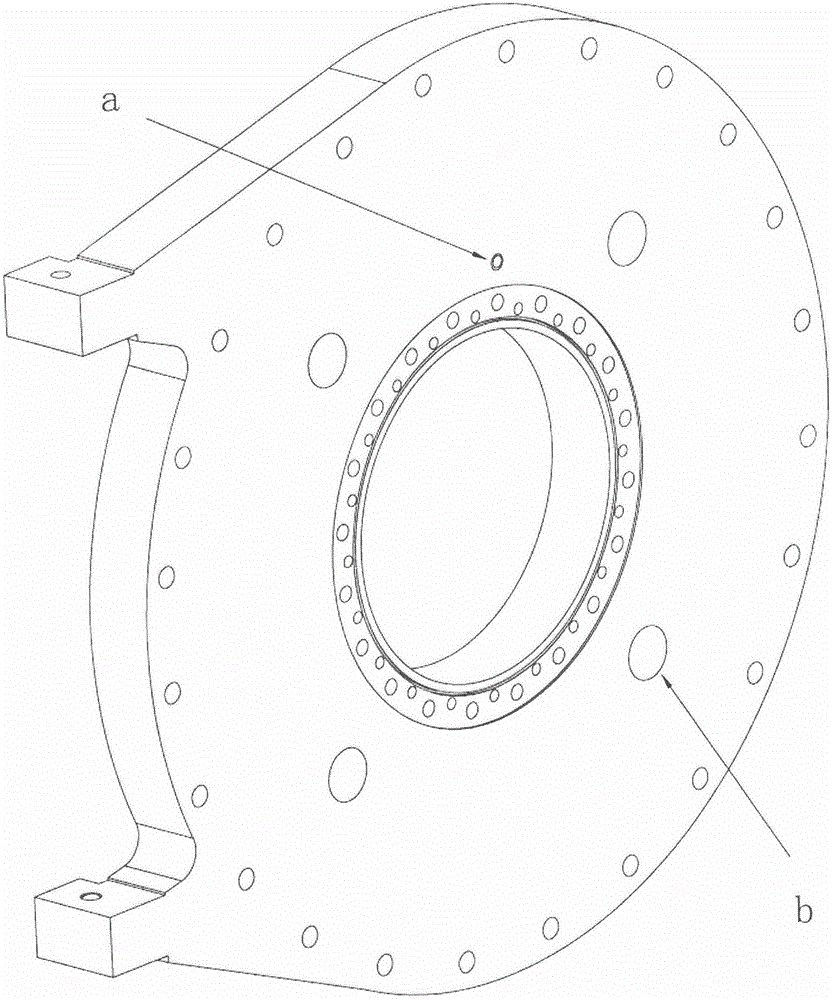

[0011] Attached below figure 1 , attached figure 2 , attached image 3 , to further describe the specific embodiments of the present invention.

[0012] A thermal grinder grinding device, among the two grinding discs of the thermal grinder grinding device, one grinding disc is a rotating grinding disc, and the other grinding disc is an axially moving grinding disc; the axially moving grinding disc is connected to the grinding disc by four guide cylinders The mounting plates of the gap adjustment mechanism are connected to each other, and are driven by the grinding disc gap adjustment mechanism to move axially.

[0013] The thermal grinder grinding device consists of a rotating grinding disc, an axially moving grinding disc, a main shaft, a rear bearing, a rear bearing seat, a thrust plate, a hydraulic thrust bearing, a front bearing seat, a front bearing, a mechanical seal, a grinding chamber shell, and a side door , 4 guide cylinders, a grinding disc gap adjustment mechan...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com