cement soil mixing pile machine

A technology for cement-soil mixing and piling machine, which is applied in sheet pile wall, construction, infrastructure engineering and other directions, and can solve problems such as unsatisfactory mixing effect.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

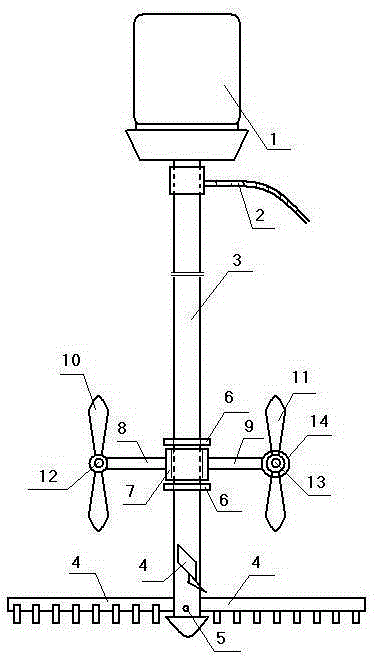

[0011] Accompanying drawing is a kind of concrete embodiment of the present invention, and the lower end of motor A1 of this embodiment is connected with drill pipe 3, and the lower end of drill pipe is fixed with stirring bit 4, and the lower end of drill pipe is also provided with slurry outlet 5, and the upper end of drill pipe is provided with inlet. Slurry pipe 2, a casing 7 is provided at the lower part of the drill pipe, and the upper and lower ends of the casing are blocked by two retaining rings 6 fixed on the drill pipe. There is a central shaft 12 inside, and one end of the central shaft is fixed with two paddles A10, and the paddles A are arranged symmetrically with the central shaft as the axis; Two paddles B11 are fixed on the shaft 13, and the paddles B are symmetrically arranged with the motor shaft as the axis.

[0012] The angle between the plane where the paddle A on the upper part of the central axis is located and the central axis is 45°, the opposite angl...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com