Pump station structure and pump station water in-out method

A pumping station and water inlet technology, which is applied in pumping stations, water supply devices, buildings, etc., can solve the problems of large area of the pumping station, unstable flow pattern, and large inertia of water flow, so as to improve the land utilization rate and improve the efficiency of the pumping station. Small footprint effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

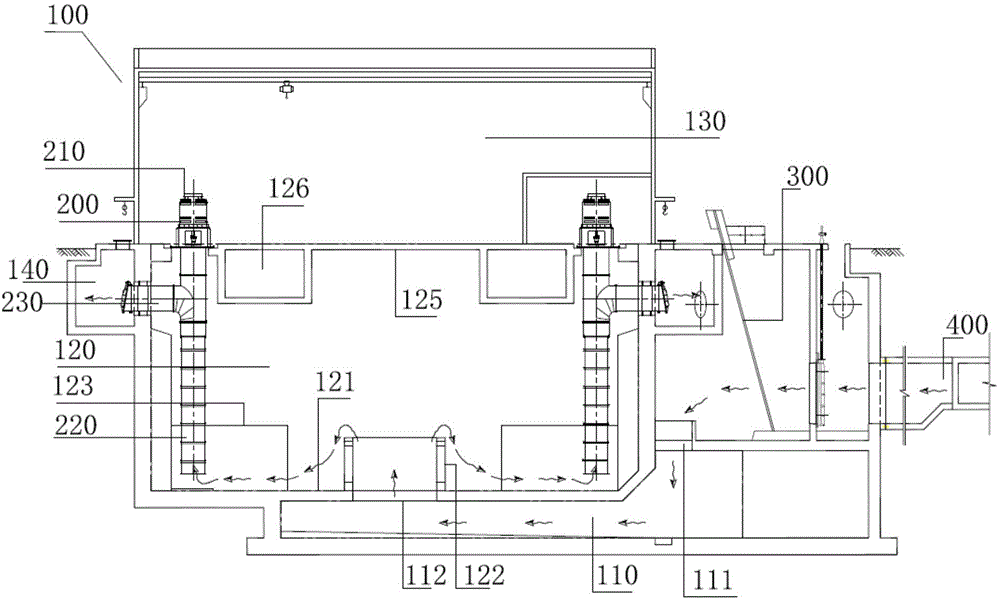

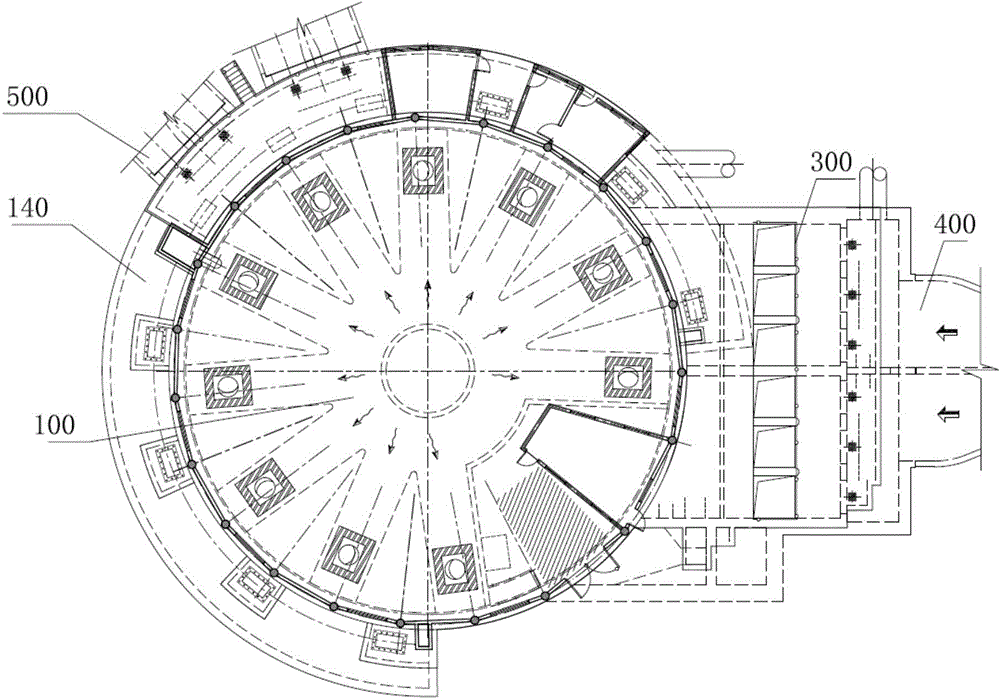

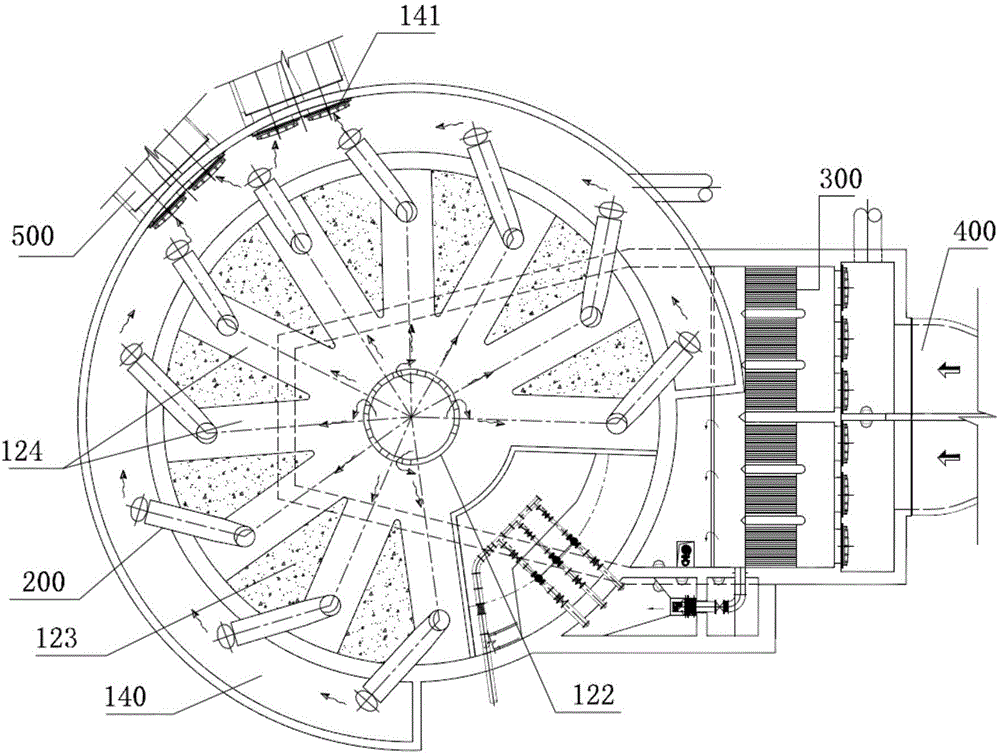

[0028] Such as figure 1 As shown, a pump station structure in this embodiment includes a pump room main body 100 and a water pump unit 200. The pump room main body 100 is sequentially arranged as a water inlet bottom layer 110, a water collection middle layer 120 and an electromechanical control top layer 130 from bottom to top. The water bottom layer 110 is provided with a water inlet 111 for introducing external water flow and a water distribution port 112 for introducing the water flow into the water collection intermediate layer, and the water distribution port 112 is conductively arranged on the bottom plate 121 of the water collection intermediate layer 120; The motor head 210 of the water pump unit 200 is arranged in the electromechanical control top layer 130, the water inlet pipe 220 of the water pump unit 200 is arranged in the water collection middle layer 120, and there is provided on the outside of the water collection middle layer 120 for leading out the water flo...

Embodiment 2

[0034] This embodiment proposes a method for pumping water in and out, including the following steps:

[0035]Step 1. The water flow directly falls into the water inlet bottom of the main body of the pump house.

[0036] Step 2: The water flows upwards and enters the water-collecting middle layer of the main body of the pump house.

[0037] Step 3: The water flow in the water-collecting intermediate layer is lifted by the water pump unit and then discharged into the water outlet pressure well.

[0038] Step 4, discharging the water from the outlet pressure well.

[0039] Specifically, such as Figure 1 to Figure 4 As shown, the water inlet and outlet method of the pumping station in this embodiment can be implemented on the pumping station structure described in the first embodiment, and the structure of the pumping station can directly refer to the description in the first embodiment, and will not be repeated here. The specific process is as follows:

[0040] Step 1: The ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com