Heavy-duty hydraulic support trackless transport vehicle and support trackless tank entry method

A technology of hydraulic supports and transport vehicles, which is applied in the directions of motor vehicles, earth drilling, transportation and packaging, etc. It can solve the problems of time-consuming and labor-consuming, complicated support transfer links, and low efficiency of heavy-duty hydraulic supports. It achieves compact size, space-saving effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

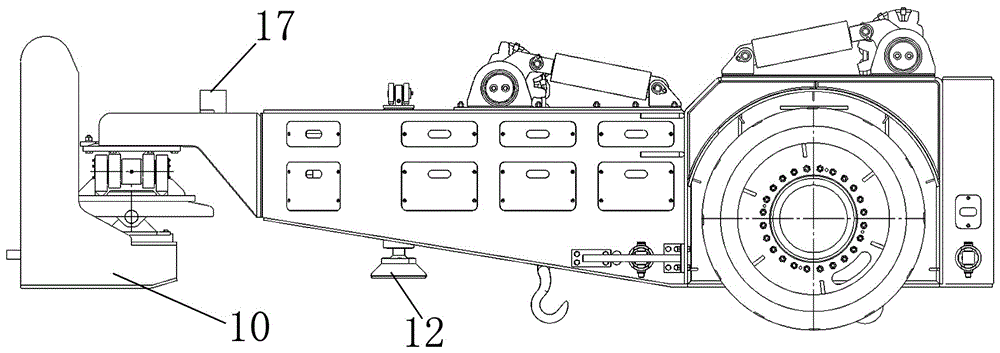

[0025] Such as figure 1 , 2 As shown, a heavy-duty hydraulic support trackless transport vehicle includes a U-shaped frame 9, a lifting mechanism 11 controlled by the hydraulic system of the tractor, a walking system 16, a supporting mechanism 12, a tightening mechanism 13, and an anti-collision block (14). The U-shaped frame 9 is a slope type structure with a low front part and a variable cross-section. A quick change mechanism 10 is installed; a support mechanism 12 is provided at the bottom of the fast transport vehicle; the lifting mechanism 11 is fixed on the upper plane of the U-shaped frame 9 in a back-to-back manner.

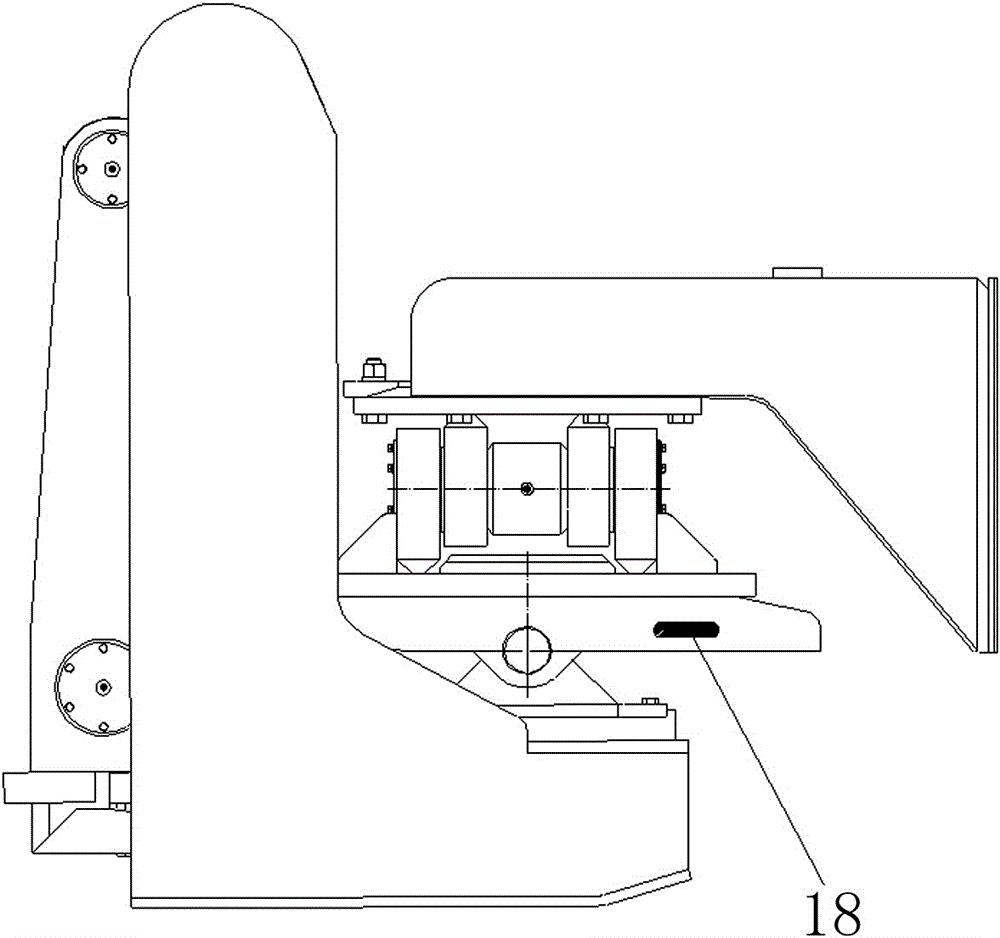

[0026] Such as image 3 As shown, the quick-change mechanism 10 is an integrated plug-in quick connection block, and the hydraulic pipeline is integrated into the plug-in integrated block 17, and the plug-in integrated block is provided with a plug-in and quick-release handle 18; the quick-change mechanism 10 The front end is connected to the explosio...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com