A fully automatic production line for power lithium batteries and its production process

A production process, lithium battery technology, applied in the direction of electrolyte battery manufacturing, non-aqueous electrolyte battery, final product manufacturing, etc., to achieve the effect of full automation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

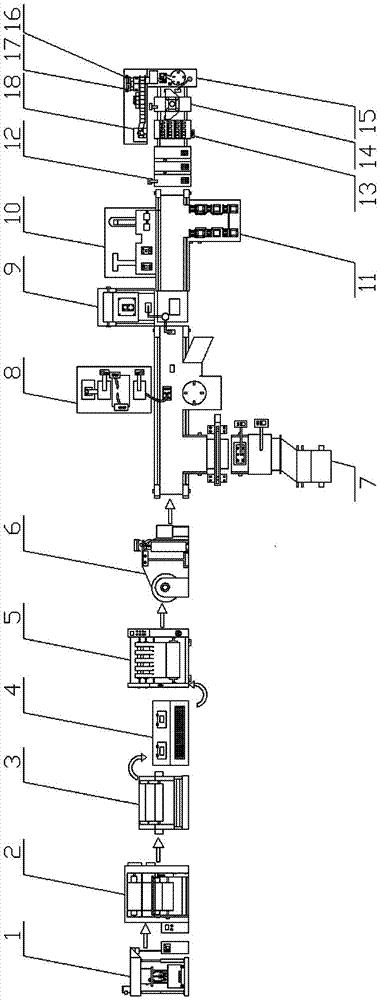

[0066] first combined with figure 1 Explain the fully automatic production line for power lithium batteries:

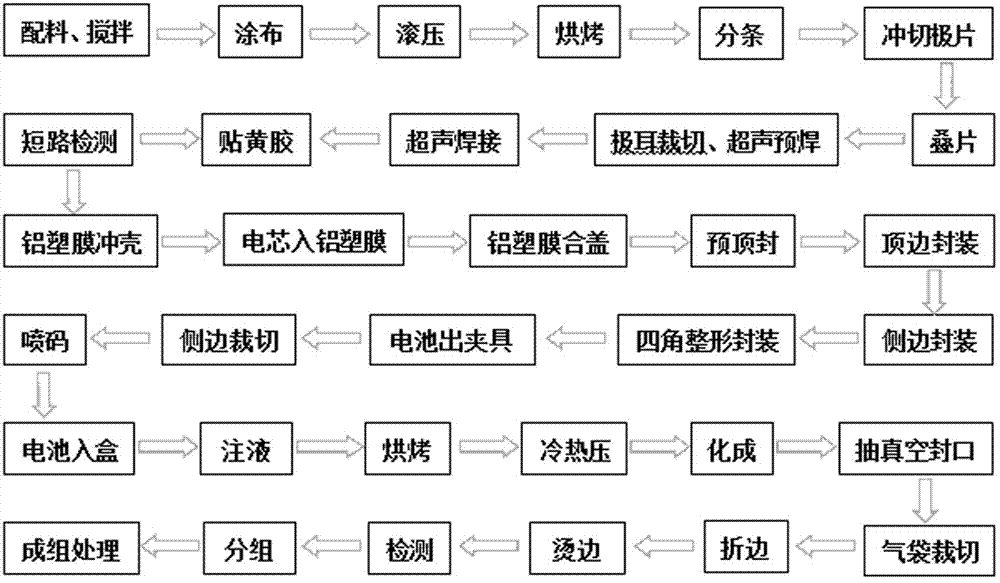

[0067] The production line consists of pole piece production unit, battery assembly unit, battery liquid injection unit and delivery processing unit. The automatic control system of each unit mainly uses PLC, industrial computer, hydraulic and pneumatic components for electrical control, and the transmission and transfer are in charge of the conveyor belts inside and between the units.

[0068] pole piece production unit

[0069] The pole piece production unit is composed of 2 mixers 1, 2 coating machines 2, 1 rolling machine 3, 1 continuous drying machine 4, 2 slitting machines 5 and 8 punching machines 6, in turn The pole piece production unit performs the processes of mixing ingredients, coating, rolling, baking, slitting and punching pole pieces, and transfers them to the battery assembly unit through the conveyor belt after completion.

[0070] The operation...

Embodiment 2

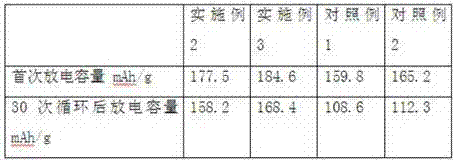

[0103] The negative electrode material in Example 1 is a modified negative electrode material, and its preparation method steps: mix 90Kg of modified lithium titanate, 15Kg of acetylene black and 15Kg of PVDF evenly, then add 20Kg of organic solvent N-methyl-2-pyrrolidone, and mix well , that is;

[0104] The preparation method of the modified lithium titanate is as follows: take 18Kg of lithium hydroxide, 12Kg of metatitanic acid, and 4Kg of terpineol, add 300Kg of deionized water, heat to 55°C, and keep for 4 hours to obtain a suspension Add 17Kg of oleic acid, 3Kg of hydrogenated castor oil, 10Kg of graphene, 3Kg of titanium dioxide, 3Kg of dibenzoyl peroxide, 15Kg of silane coupling agent, and 8 Kg of surfactant into the suspension, stir evenly, and heat to 55°C , kept for 2 hours to obtain a modified suspension; filter the modified suspension with a microfiltration membrane, sinter the obtained particles at 1150° C. for 7 hours, and cool to room temperature.

Embodiment 3

[0106] In the present embodiment, oleic acid is vulcanized and modified, and the modification method is: in a three-necked flask equipped with a stirring device, add 50 g of oleic acid, and under constant stirring, add 15 g of sulfur monochloride (S 2 Cl 2 ), control the reaction temperature below 40°C, after the dropwise addition, continue to react for 2 hours, slowly add about 100 ml of sodium polysulfide solution to the reactant, stir and react fully, remove the water layer, and then add a little reducing Iron powder, remove free sulfur in the reaction system, filter to obtain oily matter, that is all.

[0107] The preparation method of the modified negative electrode material, the steps are: mix 90Kg of modified lithium titanate, 15Kg of acetylene black and 15Kg of PVDF evenly, then add 20Kg of organic solvent N-methyl-2-pyrrolidone, and mix evenly to get ready;

[0108] The preparation method of the modified lithium titanate is as follows: take 18Kg of lithium hydroxide,...

PUM

| Property | Measurement | Unit |

|---|---|---|

| depth | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com