Offshore oil platform hydraulic pump test trolley

A technology for offshore oil and hydraulic pumps, which is used in pump testing, liquid variable capacity machinery, machines/engines, etc. It can solve the problem that the hydraulic pump cannot be moved to the test bench for testing, the transportation in the offshore operation area is inconvenient, and the hydraulic pump detection and fault maintenance Important issues, etc., to achieve the effect of convenient use and simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0013] In the following, the present invention will be further described in conjunction with the accompanying drawings and specific embodiments, so as to understand more clearly the technical idea claimed in the present invention.

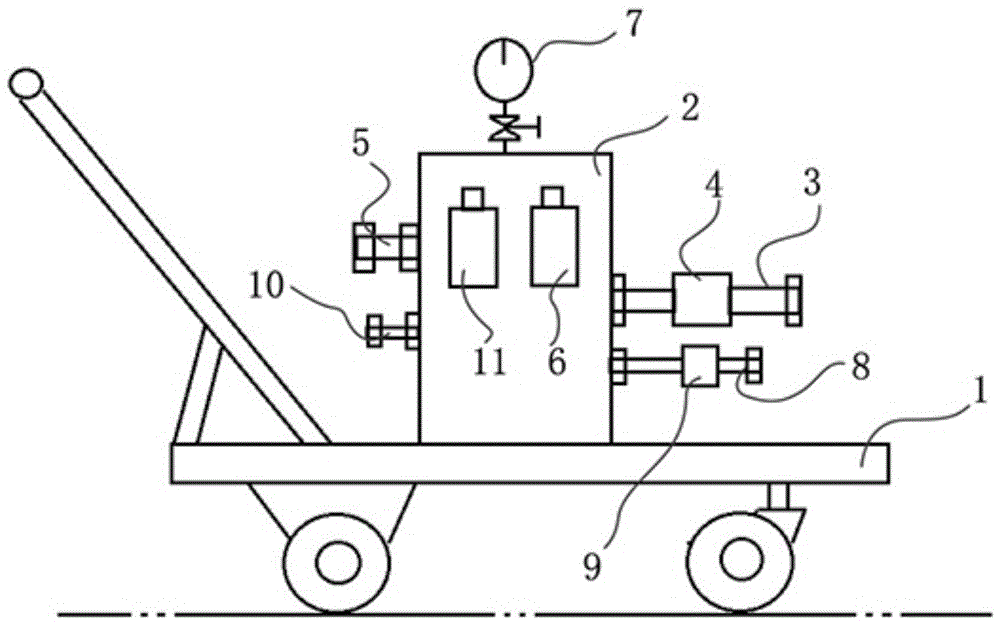

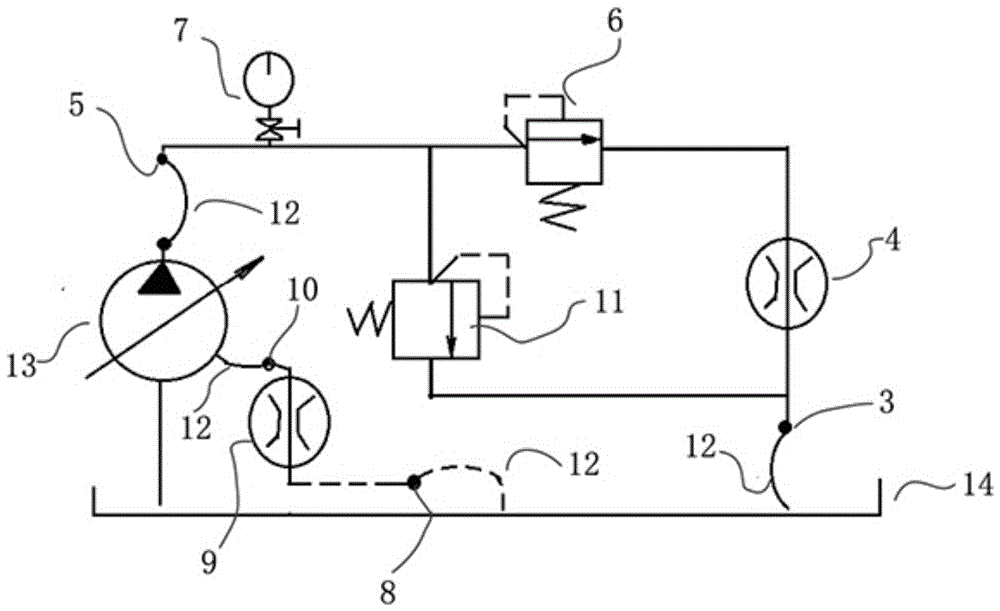

[0014] Such as Figure 1-2 The hydraulic pump test trolley of the offshore oil platform of the present invention includes a trolley 1 and a test device, and the test device includes an oil circuit block 2, a first pipe joint 3, a first flow meter 4, a second pipe joint 5, a pressure regulator Valve 6, pressure gauge 7, third pipe joint 8, second flow meter 9, fourth pipe joint 10 and safety valve 11, wherein one end of the first pipe joint 3 is fixedly connected to the side of the oil block 2, and the first The first flow meter 4 for detecting the output flow of the hydraulic pump is installed and fixed on the pipe joint 3, and the end of the first pipe joint 3, which is fixedly connected to one side of the oil circuit block, communicates with the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com