Disk brake friction wafer attrition rate detecting system based on guide wave

A disc brake and wear degree technology, which is applied in the system field of testing engineering technology, can solve the problems affecting the safety of the car, the brake friction plate is broken, and the driver cannot grasp the wear degree of the friction plate in real time, so as to avoid sudden breakage and improve safety effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0018] The embodiments of the present invention are described in detail below in conjunction with the accompanying drawings: this embodiment is implemented under the premise of the technical solution of the invention, and detailed implementation methods and processes are provided, but the protection scope of the present invention is not limited to the following embodiments .

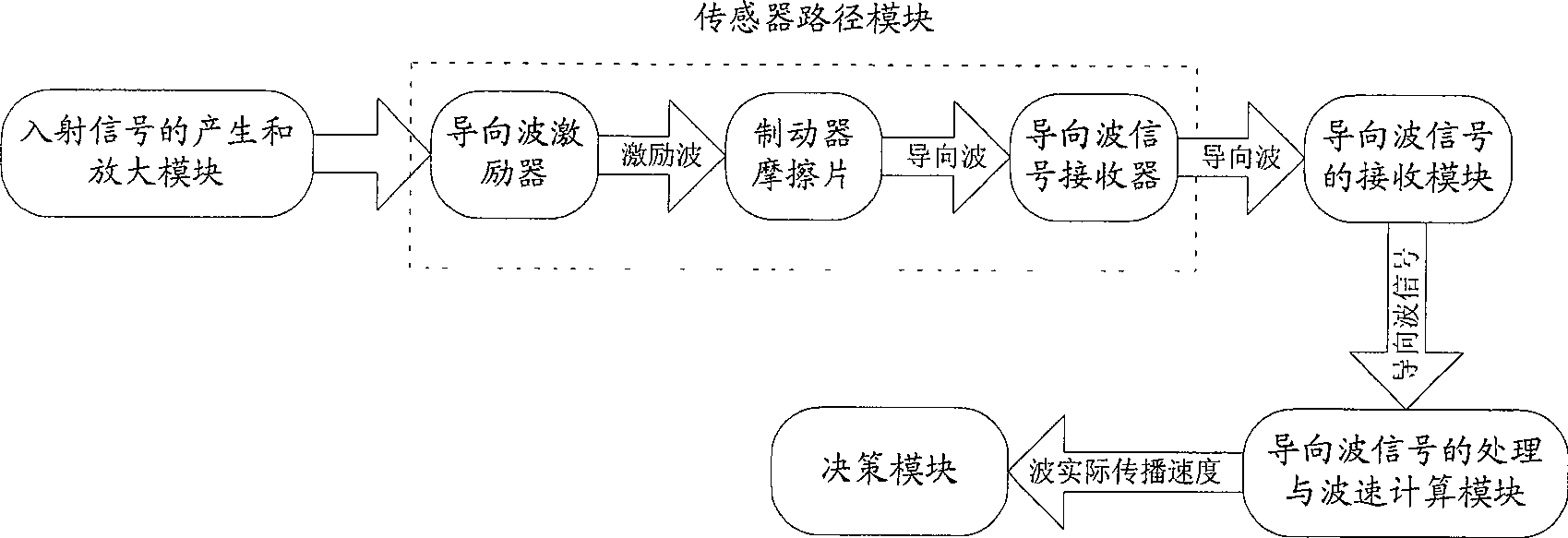

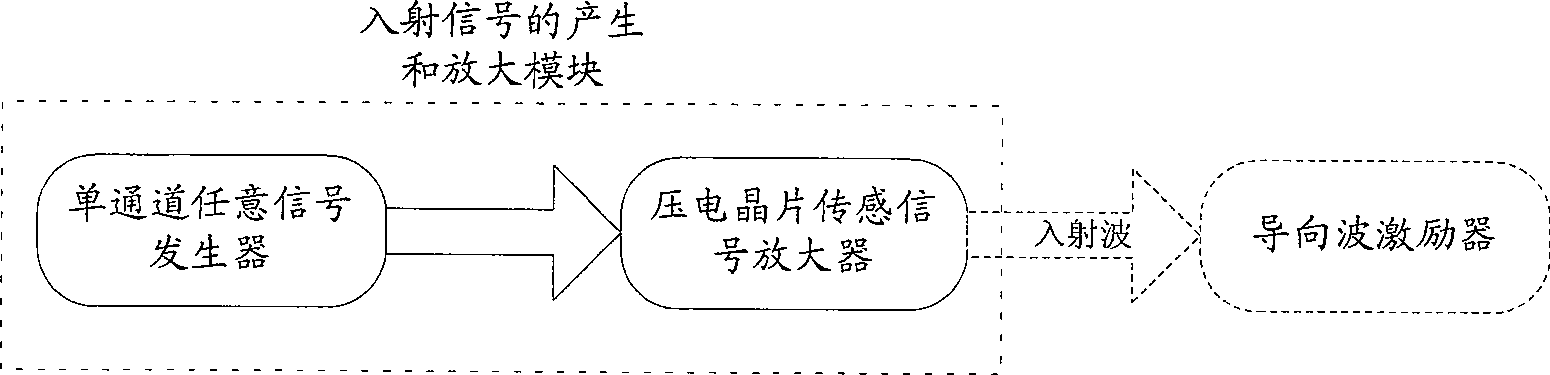

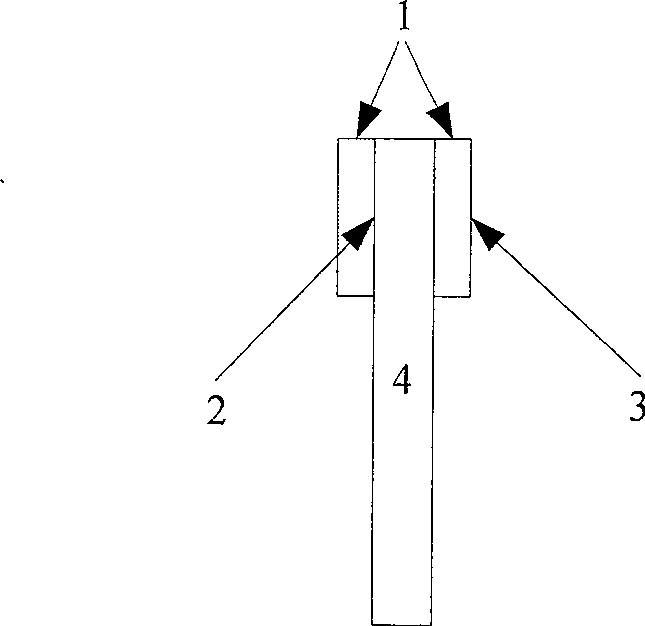

[0019] like figure 1As shown, this embodiment includes: a generation and amplification module of incident signals, a sensor path module, a receiving module of guided wave signals, a processing and wave velocity calculation module of guided wave signals, and a decision-making module, wherein: the generation of incident signals and the amplification module are responsible for Generate an excitation wave that excites the guided wave in the brake friction plate, and transmit the excitation wave to the sensor path module; the sensor path module receives the incident signal generation and the excitation wave e...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com