A detection device and working method for chemical mechanical polishing pad wear

A detection device and chemical mechanical technology, which is applied to the parts of grinding machine tools, manufacturing tools, metal processing equipment, etc., to achieve the effects of improving detection efficiency and machine utilization, fully using it, and reducing the rate of defective products

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0027] The present invention will be further described below in conjunction with the accompanying drawings and specific embodiments, but not as a limitation of the present invention.

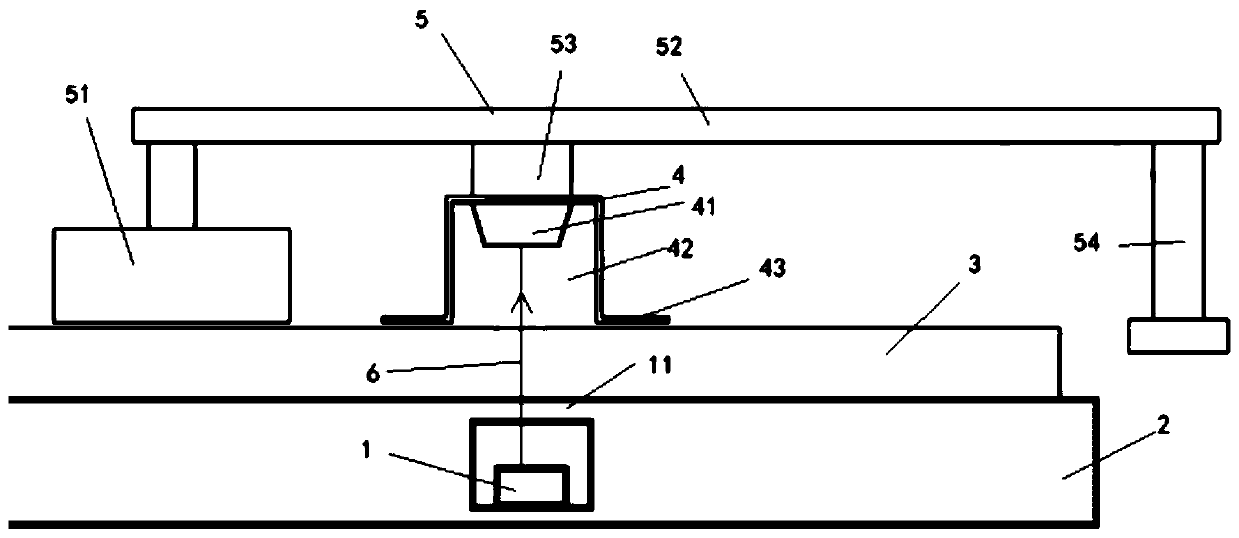

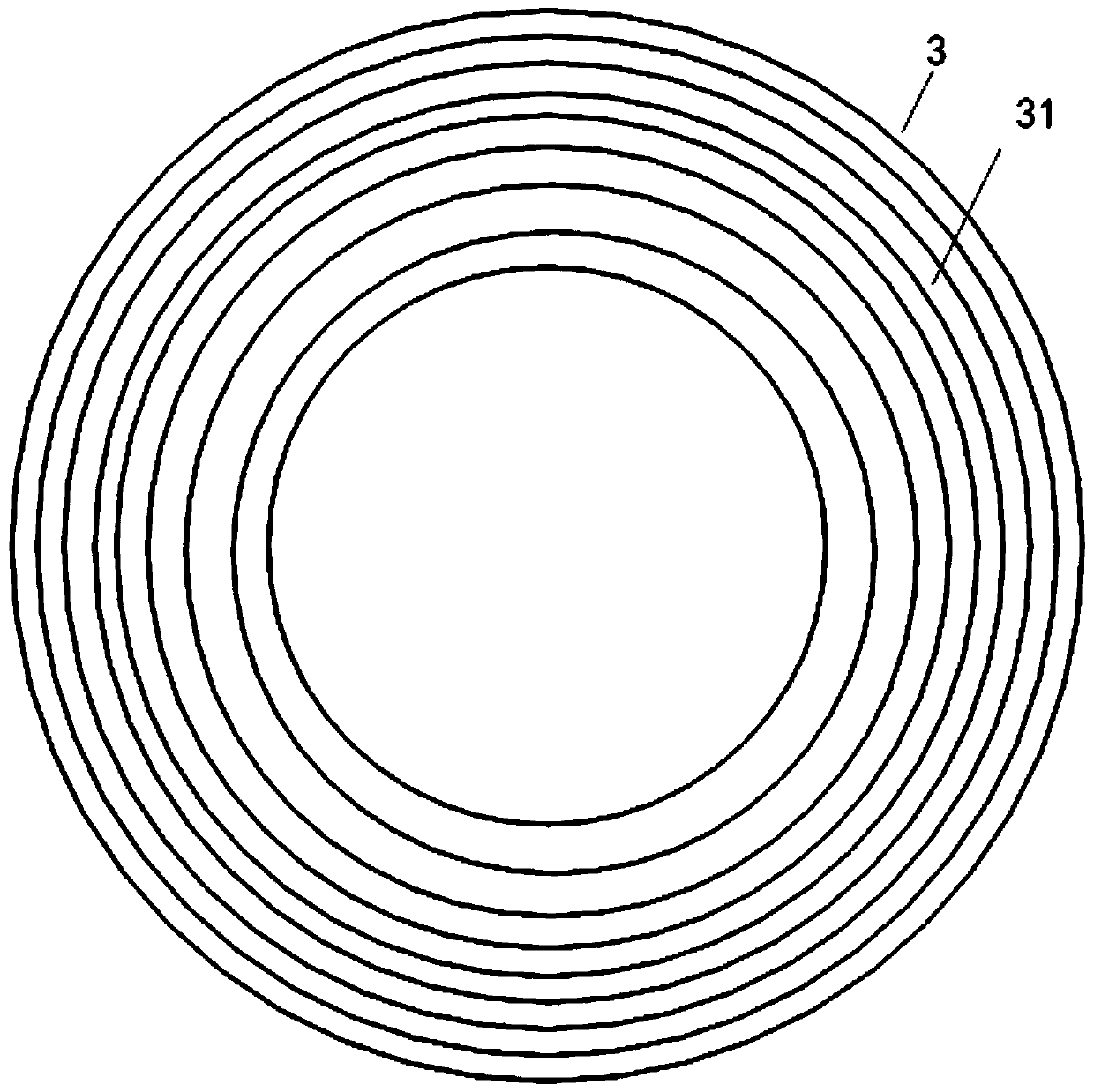

[0028] figure 1 It is a schematic diagram of a detection device for chemical mechanical polishing pad wear of the present invention. figure 2 It is a schematic diagram of a polishing pad worn by a chemical mechanical polishing pad of the present invention.

[0029] See Figure 1 to Figure 2 Shown, in a kind of preferred embodiment, a kind of detection device of chemical mechanical polishing pad wearing and tearing, wherein, comprise:

[0030] The laser light source 1 is arranged in the grinding disc 2 , and the laser light source 1 is covered with a transparent glass window 11 .

[0031] Detection device 4, detection device 4 is installed on trimmer 5, and grinding pad 3 is positioned at the below of detection device 4; Detection device 4 comprises light receiver 41, grinding pad monitor 42 ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com