Universal testing machine with detecting and leveling movable cross beam and detecting and leveling method

A technology of universal testing machine and moving beam, which is applied in the field of universal testing machine, can solve problems such as force deviation of test pieces, error in test results, and expansion of moving beam wear, so as to reduce time cost, reduce maintenance difficulty or cost, The effect of improving convenience

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0032] The structure and principle of the universal testing machine with detecting and leveling moving beam according to the present invention will now be fully described with reference to specific embodiments, so that those skilled in the art can fully understand and implement.

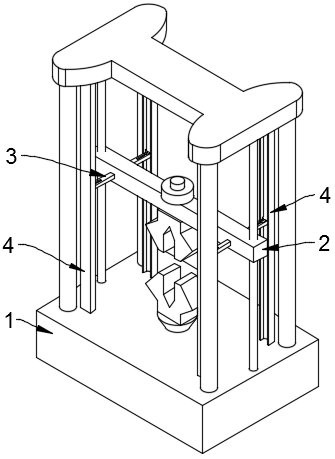

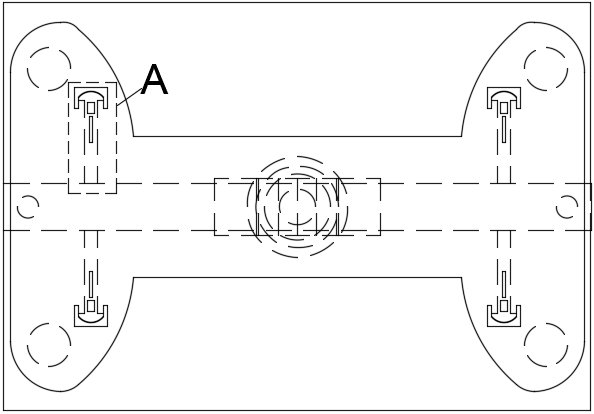

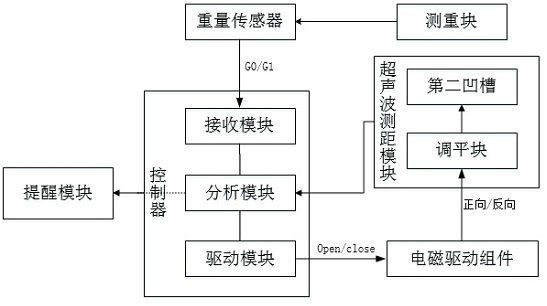

[0033] like Figure 1-Figure 6 As shown, the universal testing machine with the detection and leveling moving beam disclosed in this embodiment includes a base 1 with a drive system installed inside, a screw rod on both sides of the base 1 that is driven and rotated by the drive system, and two ends are respectively connected to the two sides of the base 1. The moving beam 2 is connected with the side screw and rotates with the screw to move up and down in a straight line; both ends of the moving beam 2 are provided with leveling detection devices near the screw; The balance wing 3, the end of the balance wing 3 is T-shaped, and the outer end surface is a convex arc shape; the guide rail 4 (universal...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com