Real-time abrasion monitoring device for cutter head of shield tunneling machine

A real-time monitoring and wear device technology, which is applied in the field of shield machines, can solve the problems of multi-tool shield machine wear monitoring and the inability to monitor wear values in real time, so as to improve detection flexibility, improve excavation efficiency, and avoid tool false alarms Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

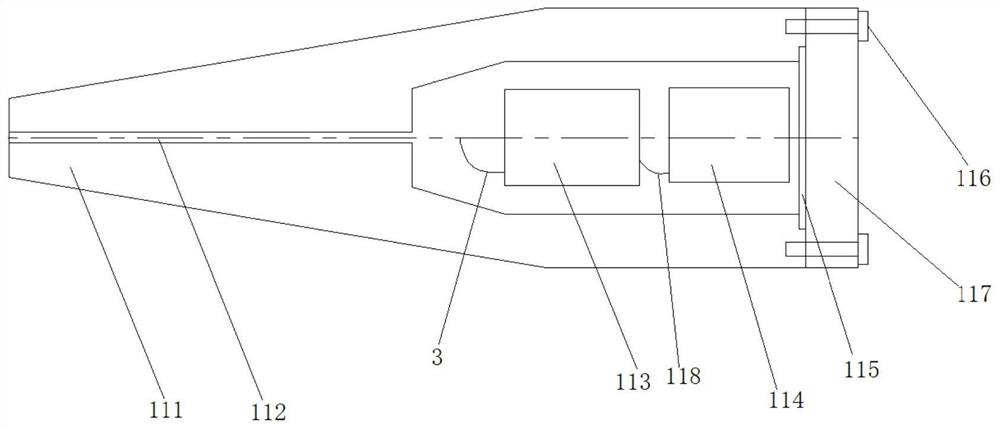

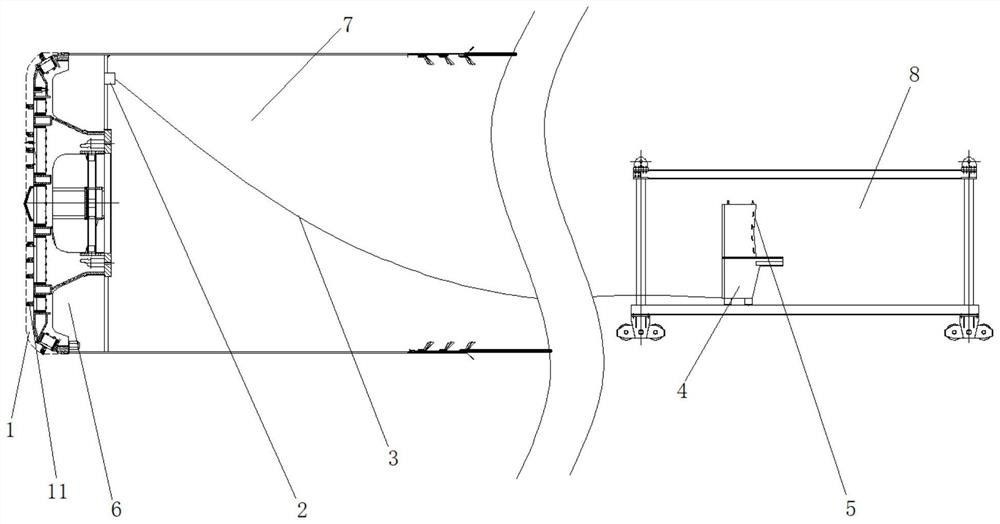

[0021] Such as Figure 1 to Figure 2 As shown, a real-time wear monitoring device for a shield machine cutterhead of the present invention includes a cutterhead end device 1, a signal receiving module 2, a PLC data processing module 4, and a monitor 5; the cutterhead end device 1 is equipped with a cutterhead end device The monitoring assembly 11, the cutterhead end monitoring assembly 11 includes a wear-resistant shell 111 and a resistance wire 112, the resistance wire 112 runs through the inside of the wear-resistant shell 111, and is arranged at the central axis position of the wear-resistant shell 111. A signal transmission module 113 and a power supply module 114 are also arranged inside the mill housing 111, and the signal transmission module 113 and the resistance wire 112 are connected by a signal cable 3, and the power supply module 114 provides power support for the signal transmission module 113 and the resistance wire 112 , the signal sending module 113 and the pow...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com