Single-row hole single-row l-type lightweight partition wall board extrusion machine double-layer output shaft reducer

A technology for lightweight partition boards and output shafts, applied in transmission boxes, mechanical equipment, gear transmissions, etc., can solve the problem of limiting the application range of extruders and finding no single-row holes and single-row L-shaped lightweight partition boards Extrusion machine double-layer output shaft gearbox literature reports, single variety and other problems, to achieve the effect of improving strength, improving butt joint strength, and expanding the application range

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0016] The present invention will be further described below in conjunction with the accompanying drawings.

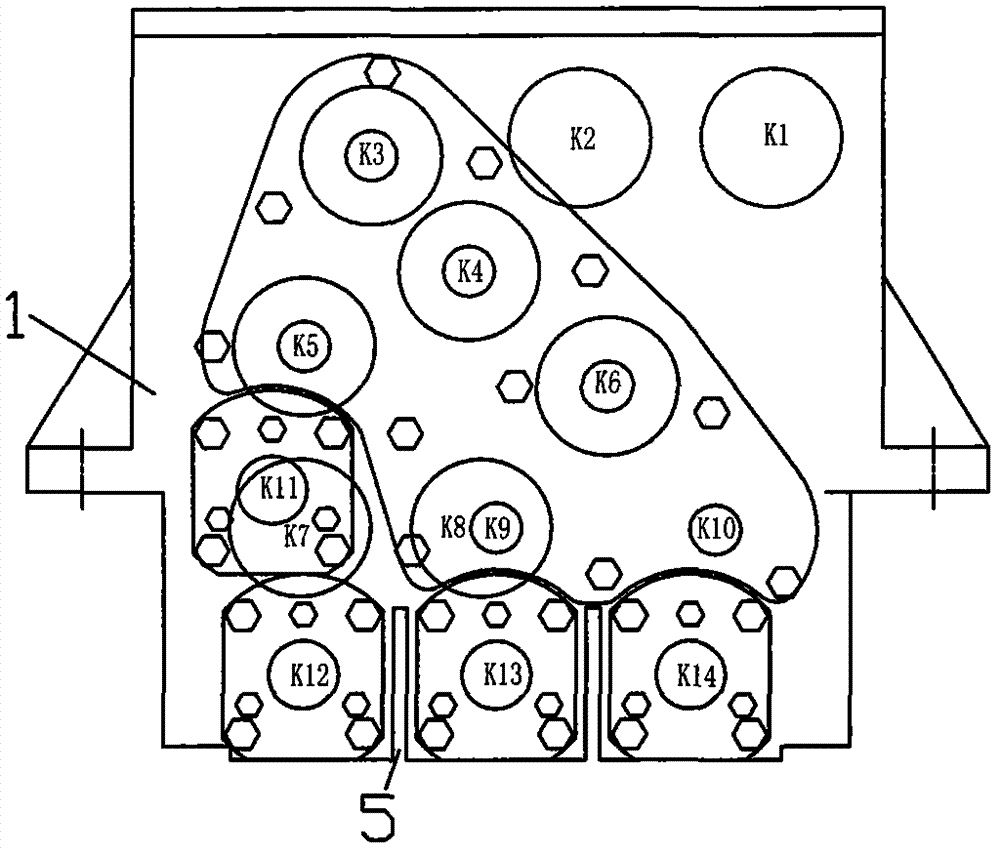

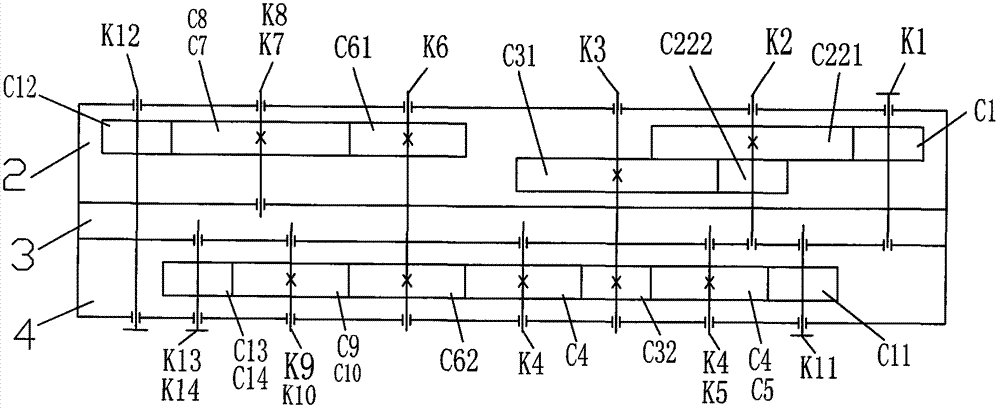

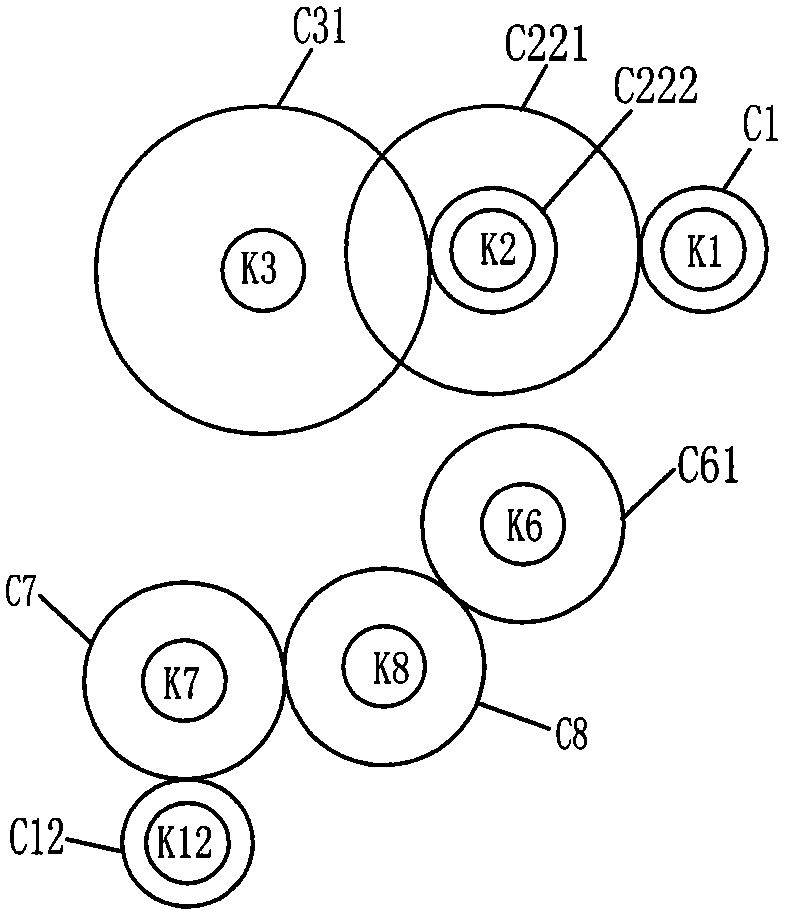

[0017] Such as figure 1 , figure 2 , image 3 , Figure 4 As shown, the single-row hole single-row L-type lightweight partition board extruder double-layer output shaft reduction box includes a box body 1, and the box body 1 includes I box body 2, II box body 3, and III box body 4 , K7 axis K7, K8 axis K8 are arranged in the I box 2; K1 axis K1, K2 axis K2 are arranged in the I box 2, II box 3; K4 is arranged in the III box 4 Axis K4, K5, K5, K9, K9, K10, K10, upper output shaft K11, K11 and lower output shaft K13, K13, K14, K14; inside the I box 2, II box 3, and III box 4 Set K3 shaft K2, K6 shaft K6 and the lower output shaft K12 shaft K12; the K1 shaft K1 is fixed with C1 gear C1, the K2 shaft K2 is fixed with C221 gear C221, C222 gear C222, and the K3 shaft K3 is fixed C31 gear C31, C32 gear C32, C1 gear C1 meshes with C221 gear C221, C222 gear C222 meshes wi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com