Double-layer output shaft reduction gearbox of double-row L-shaped light partition board extrusion machine

A light-weight partition board and extruder technology, which is applied in the direction of mechanical equipment, transmission parts, gear transmission, etc., can solve the problems of poor butt joint strength, single output box of the extruder, and limit the application range of the extruder, etc. , to achieve tight connection and improve the effect of butt joint strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

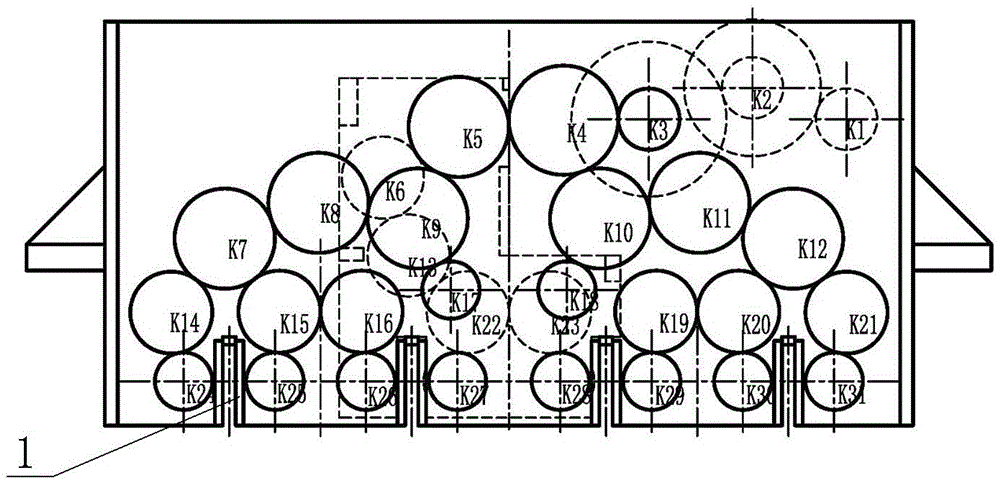

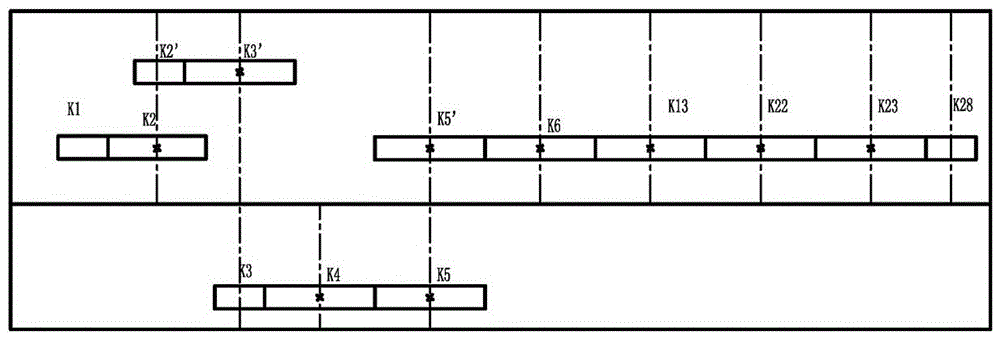

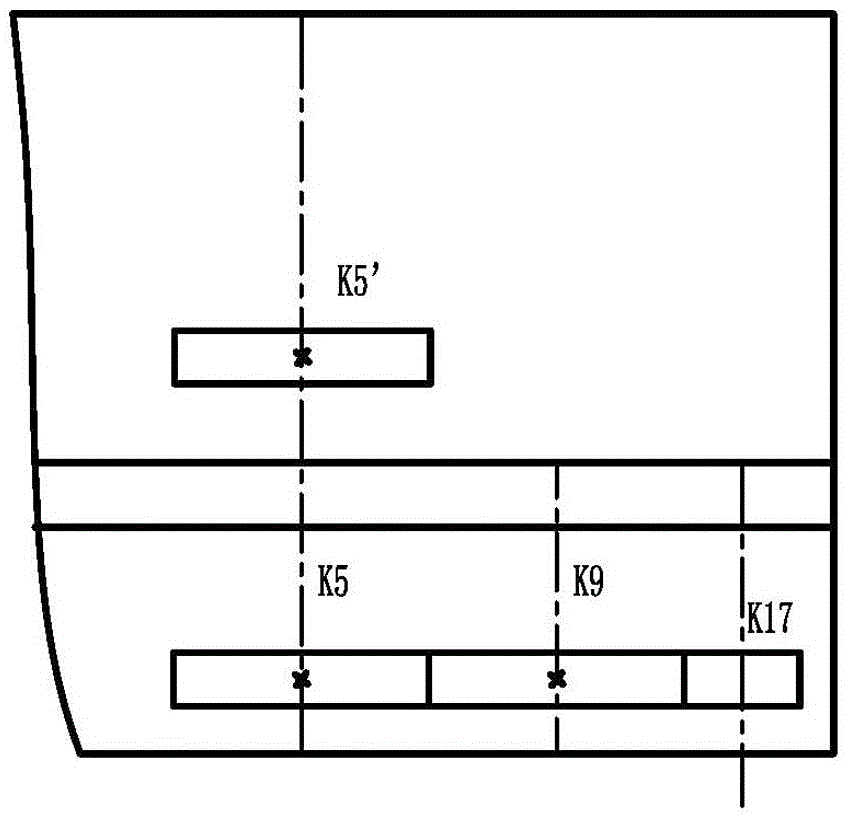

[0022] Embodiment 1: as figure 1 , figure 2 , image 3 , Figure 4 , Figure 5 , Figure 6 , Figure 7 , Figure 8 , Figure 9 , Figure 10 , Figure 11 As shown, a double-row L-shaped lightweight partition board extruder double-layer output shaft reduction box includes a box body, and the box body is provided with K1 gear, K2 gear, K2' gear, K3 gear, K3' gear Gear, K4 gear, K5 gear, K5' gear, K6 gear, K7 gear, K8 gear, K9 gear, K10 gear, K11 gear, K12 gear, K13 gear, K14 gear, K15 gear, K16 gear, K17 gear, K18 gear , K19 gear, K20 gear, K21 gear, K22 gear, K23 gear, K24 gear, K25 gear, K26 gear, K27 gear, K28 gear, K29 gear, K30 gear, K31 gear, and the K1 gear is meshed with the K2 gear , the K2' gear meshes with the K3' gear, the K2 gear and the K2' gear are connected together through a shaft, the K3 gear and the K3' gear are connected together through a shaft, and the K5 gear and K5' gears are connected together by shafts, the K3 gears, K4 gears, K5 gears, K9 ge...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com