Self-tight sealing piston gas holder

A self-tightening sealing, gas tank technology, applied in the field of gas storage tanks, can solve problems such as gas leakage safety hazards, and achieve the effects of low use cost, simple structure and reduced energy waste

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] Hereinafter, preferred embodiments of the present invention will be described in detail with reference to the accompanying drawings. It should be understood that the preferred embodiments are only for illustrating the present invention, but not for limiting the protection scope of the present invention.

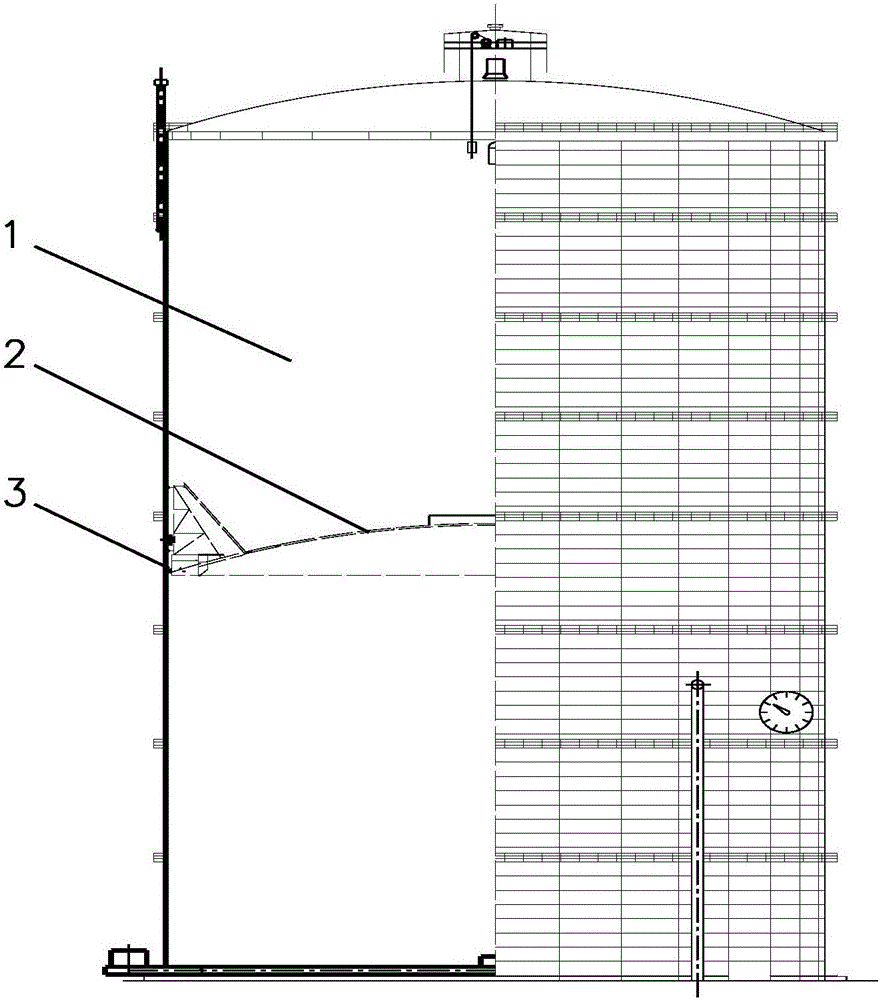

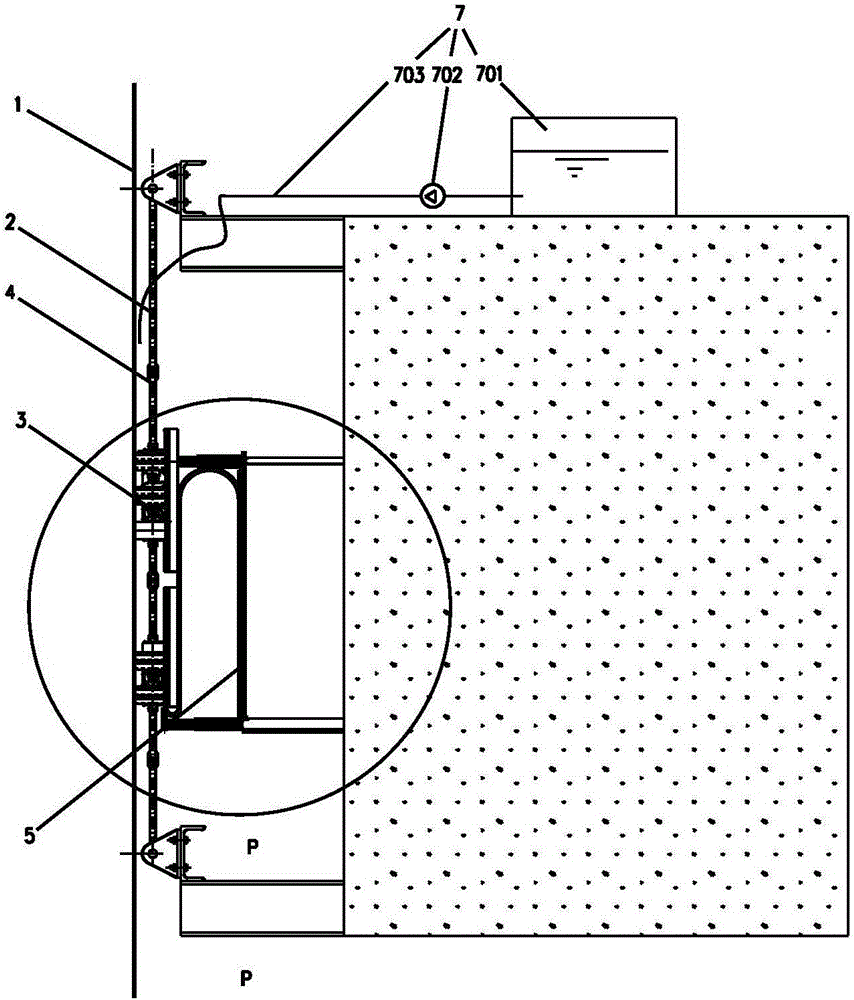

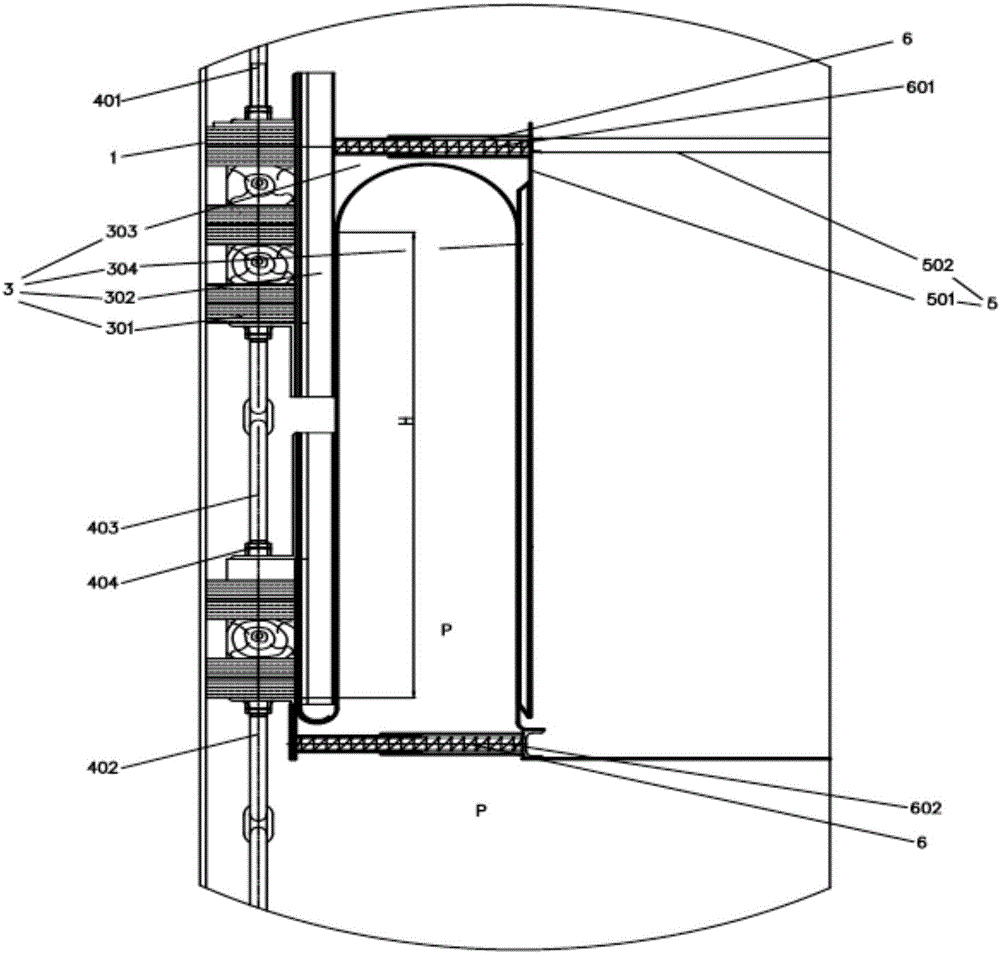

[0022] Such as Figure 1-3 As shown, the self-tightening and sealing piston gas holder of this embodiment includes a gas holder cylinder body 1 and a piston 2, and at least one set of self-tightening sealing components 3 arranged between the gas holder cylinder body 1 and the piston 2. The tight sealing assembly 3 moves up and down the traction device 4 that acts as a guide, and the fixing device 5 that fixes the sealing assembly on the piston. The self-tight sealing assembly 3 includes a sealing belt 301, a sealing belt pressing plate 302, "U" or "C" Type film 303, baffle plate 304, the opening of the "U" or "C" type film 303 faces downward, and the sealing belt pres...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com