LED module structure, double-faced adhesive tape and gluing method

A technology of LED components and double-sided adhesive tapes, which are applied to plane light sources, components of lighting devices, lighting and heating equipment, etc., can solve the problems of high labor cost, waste of double-sided adhesive materials, and complicated operation, and simplify the operation panel. , The effect of reducing production costs and increasing production capacity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0022] The content of the present invention will be further described below in conjunction with the accompanying drawings and preferred specific embodiments of the present invention. The examples given are only for explaining the present invention, not for limiting the scope of the present invention.

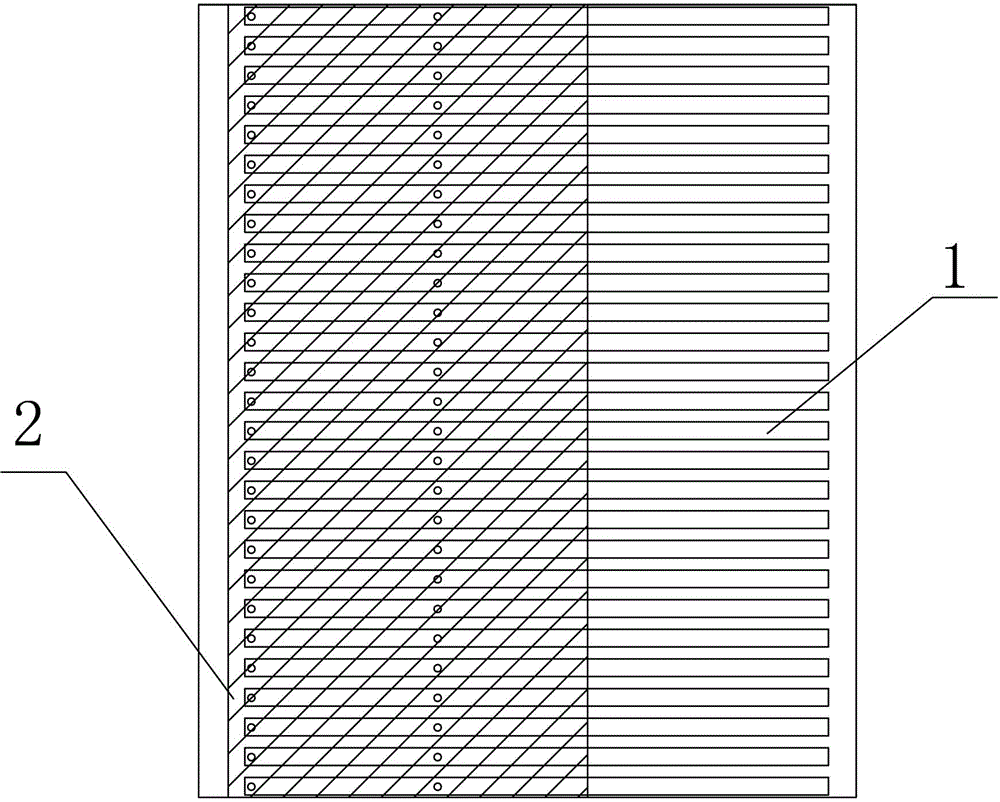

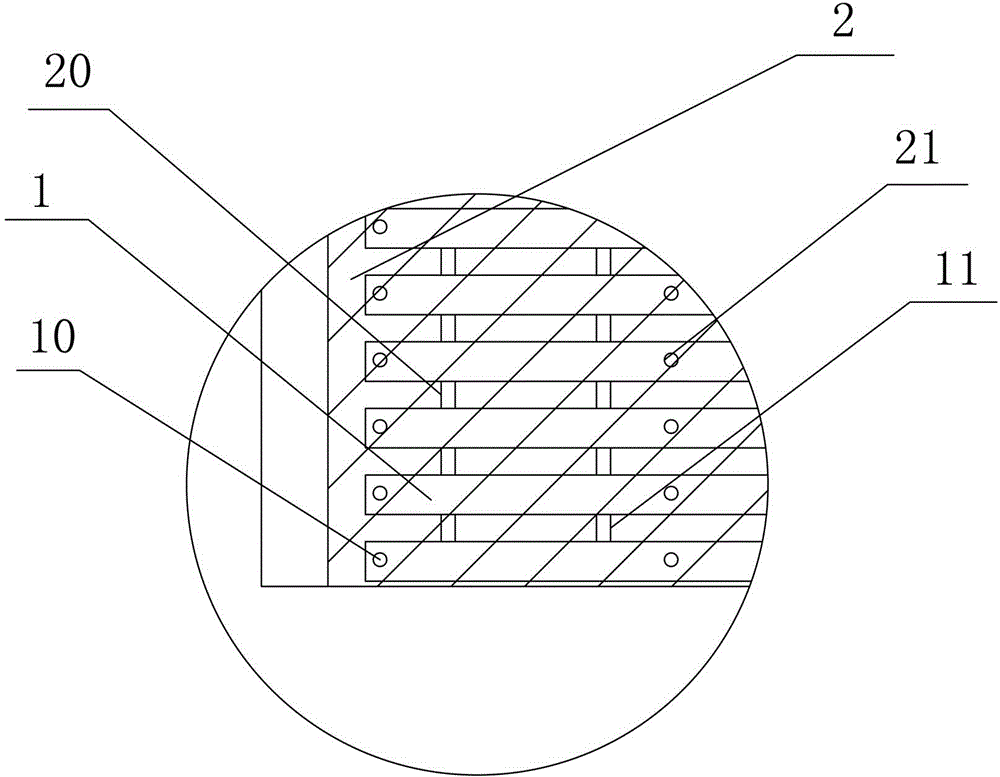

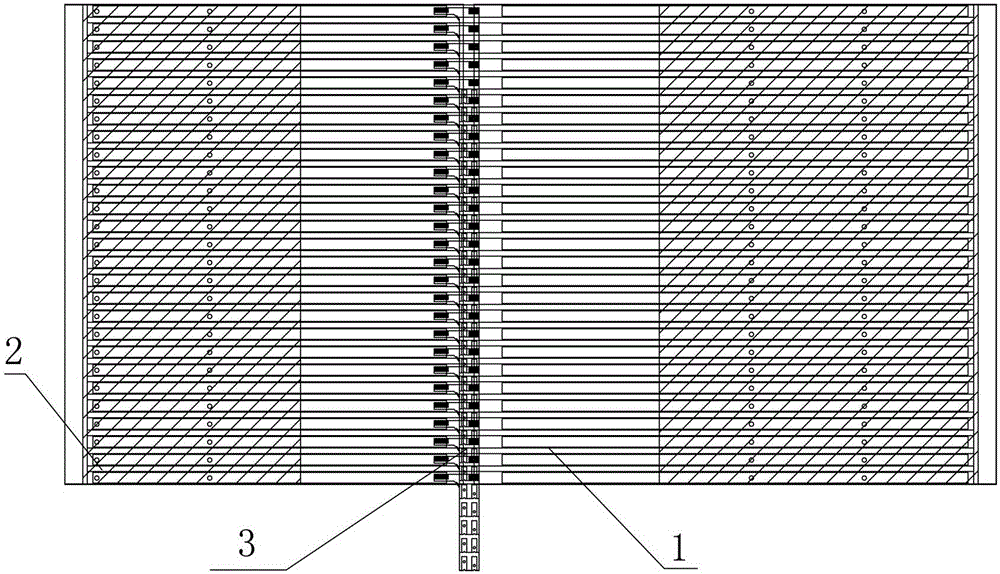

[0023] Such as Figure 1 to Figure 4 As shown in , the LED component structure described in this solution includes more than two single circuit boards 1 connected to each other through at least two circuit board connection positions 11, each circuit board 1 There are at least two positioning points 10, the circuit board described is FPC or PCB, and the circuit board described in this solution is FPC; Laminated double-sided adhesive, the double-sided adhesive 2 includes more than two units, the units are connected by double-sided adhesive joints 20, and each double-sided adhesive 2 unit is provided with The positioning hole 21 corresponding to the positioning point 10 of the ci...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com