Transfer printing plate, display screen, display device and display device manufacturing method

A technology of display screen and transfer plate, applied in the direction of instruments, nonlinear optics, optics, etc., can solve the problems of PanelID marking work, occupancy, and reduction of production line efficiency.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

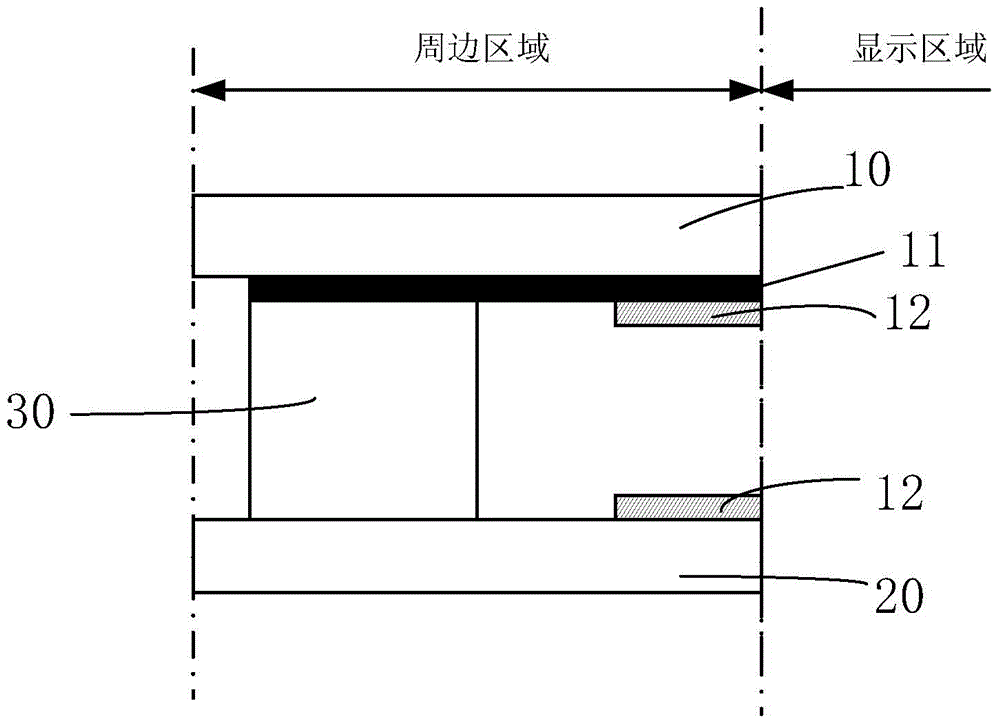

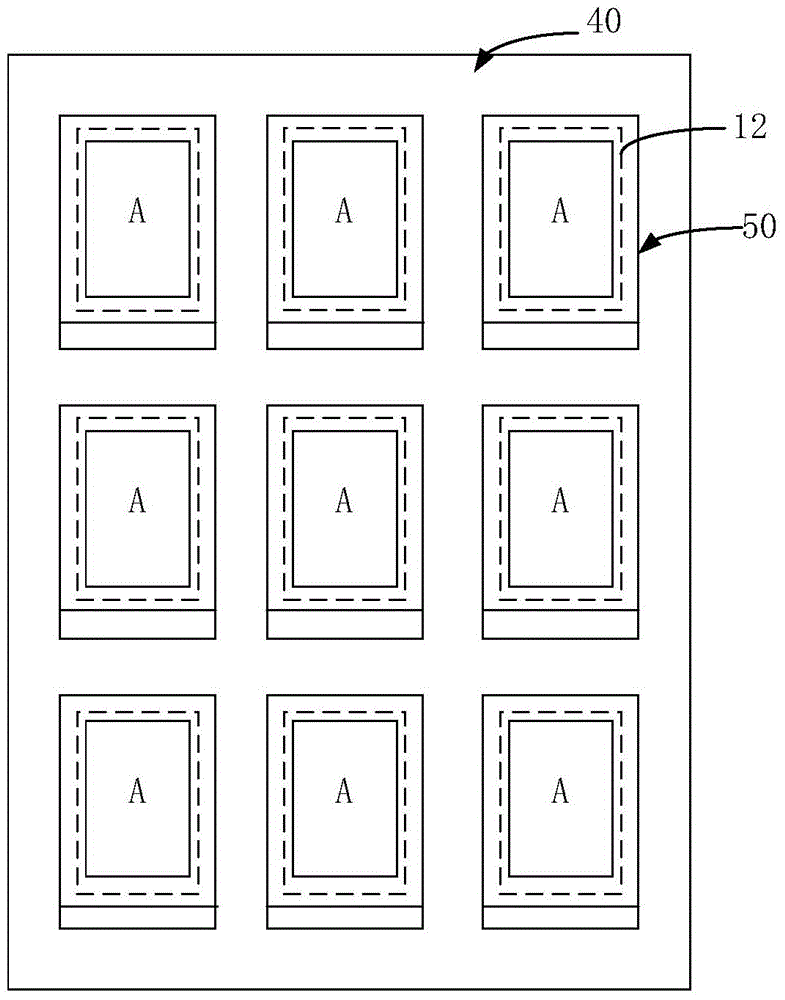

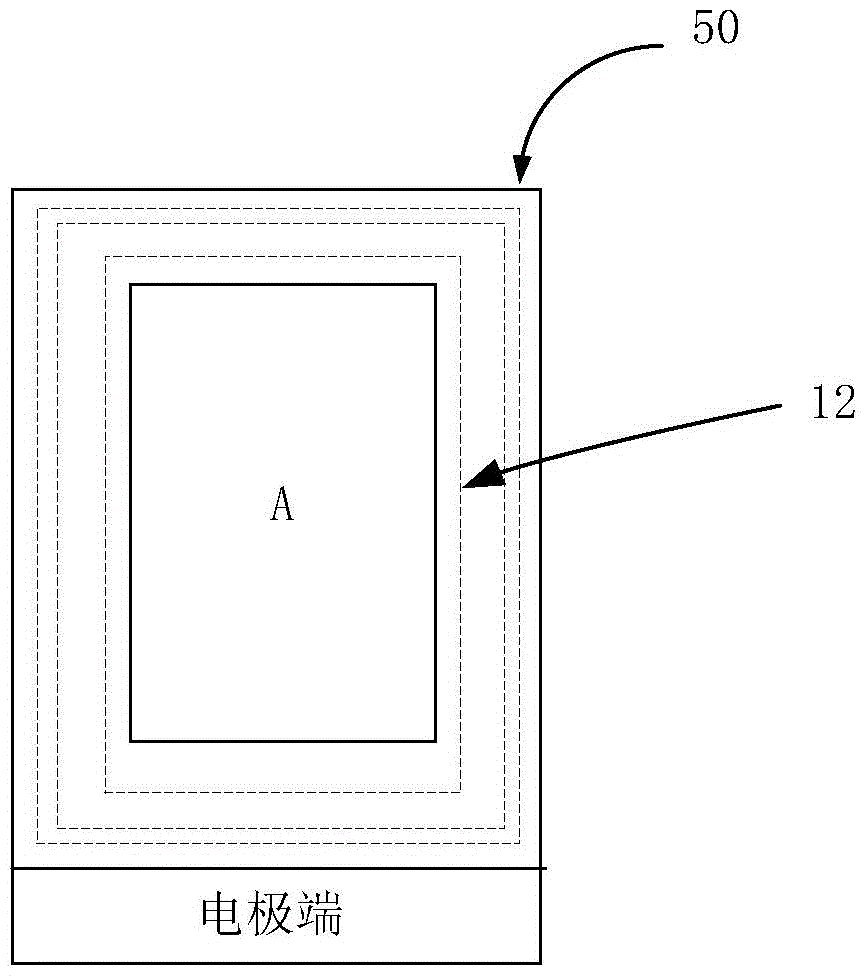

[0044] The principles and features of the present invention are described below in conjunction with the accompanying drawings, and the examples given are only used to explain the present invention, and are not intended to limit the scope of the present invention.

[0045] Aiming at the technical problems of the prior art, such as the cumbersome work of identifying the Panel ID of the unit display screen on the motherboard and taking up more production line capacity, the present invention provides a transfer board, a display screen, a display device, and a manufacturing method for the display device. It can improve the efficiency of marking unit display screens in the current production line, and effectively improve the production line production capacity through simple design changes.

[0046] Such as Figure 5 As shown, the transfer plate provided by the present invention is used to form an alignment film on a motherboard with multiple unit display screens; the transfer plate...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com