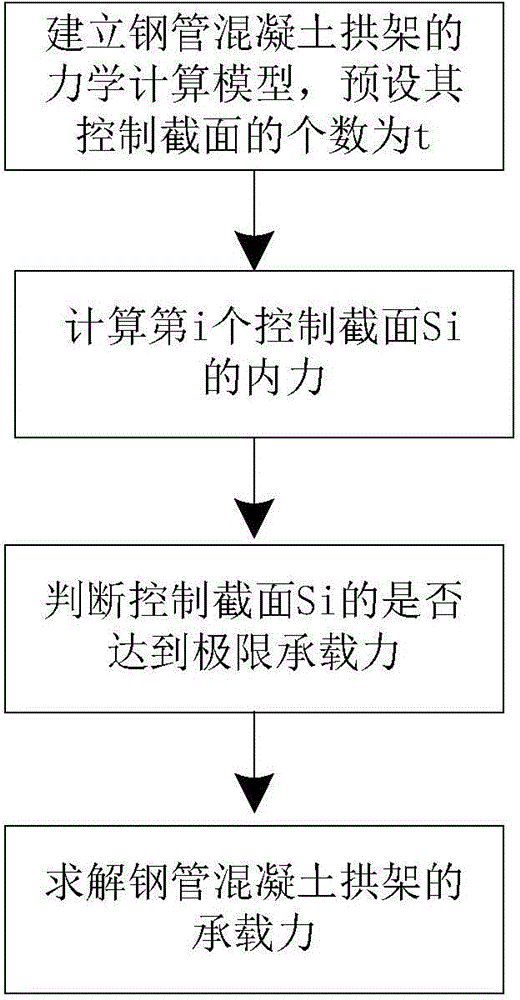

Bearing capacity determination method for concrete filled steel tube lagging jack

A steel pipe concrete and determination method technology, applied in special data processing applications, instruments, electrical digital data processing, etc., can solve the problem that the bearing capacity cannot be effectively determined, and achieve scientific and reasonable determination process, controllable calculation error, and reliable calculation results Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

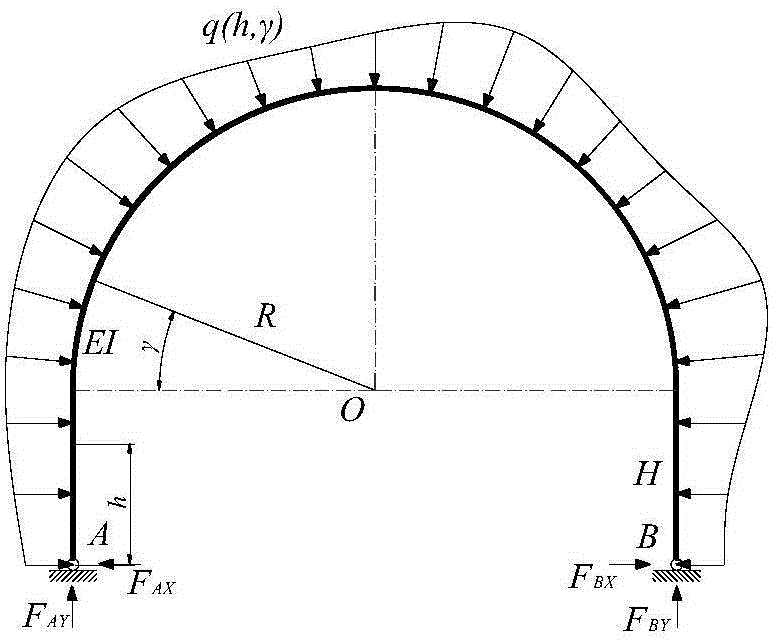

Method used

Image

Examples

specific Embodiment approach

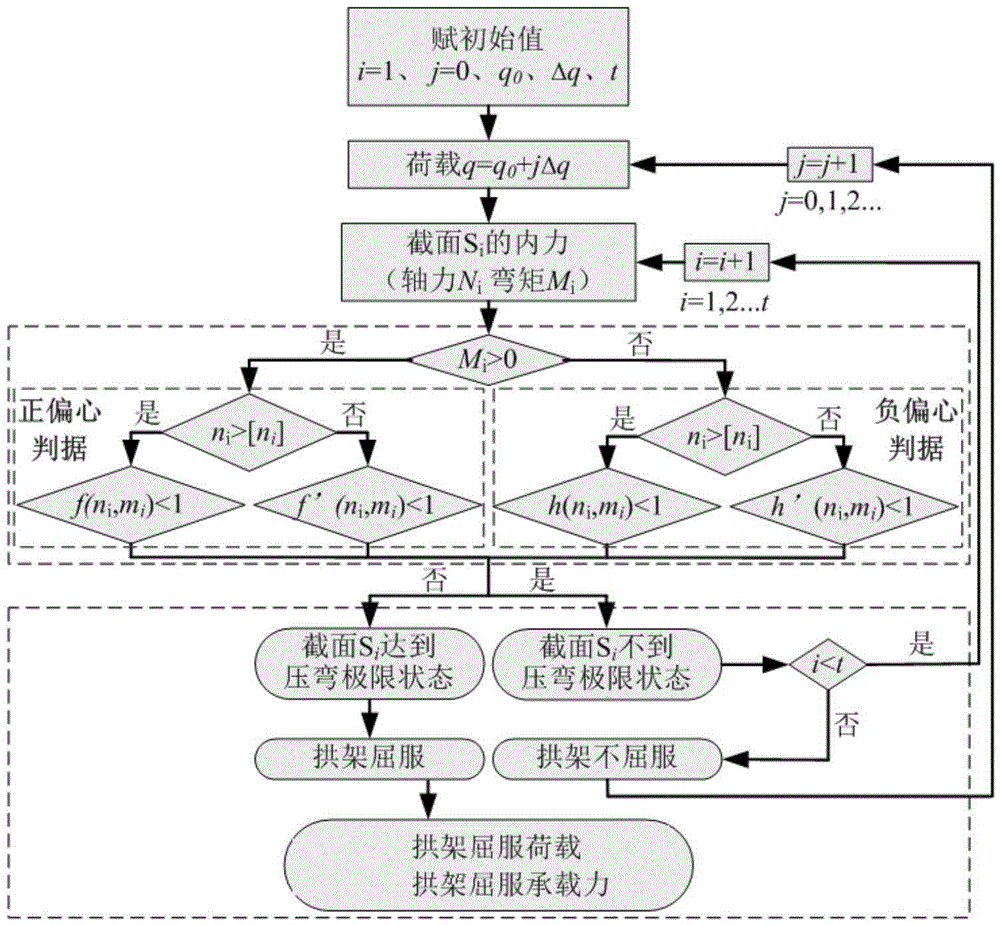

[0044] A preferred embodiment of the present invention is:

[0045] 1. Assign initial value

[0046] When the load on the arch frame is unknown, the initial load q 0 It refers to the load applied to the arch during the first step of calculation; the load step Δq refers to the increment of the load applied to the arch during the next step of calculation compared with the previous step of calculation, and the load step The smaller Δq is, the higher the calculation accuracy is; the number of control interfaces t refers to the number of sections taken from the arch, and the calculation result of the internal force of the section is the basic data for judging whether the arch has reached the bearing capacity. The larger the value, the higher the calculation accuracy.

[0047] Apply an initial load q slightly smaller than the yield load to the arch by predicting 0 =90kN / m, Δq=0.1kN / m, t=41. The meaning of the above assignment is that the arch is applied with a uniform load, and ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com