A Characterization Method for Shale Full Aperture Pore Volume

A technology of pore volume and pore size, which is applied in the fields of permeability/surface area analysis, suspension and porous material analysis, measuring devices, etc., to achieve an objective and reasonable effect of characterization

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

[0042] In this embodiment, the shale full-pore pore volume characterization is performed on the shale in southeast Chongqing, including the following steps:

[0043] (1) Sample preparation: firstly, the shale is made into a cylinder with a diameter of 2.5 cm and a length of 3 cm using a coring drill bit and a core cutting device;

[0044] Take 10g of shale, crush it into a powder with a diameter of 0.18mm, and divide it into two parts to make the first powdery shale and the second powdery shale suitable for low-pressure nitrogen adsorption experiments and low-pressure carbon dioxide adsorption experiments.

[0045] (2) Sample pretreatment: the above three samples were placed in a 110°C incubator for 12 hours for dehydration treatment; -4 Under the condition of MPa, the degassing treatment is carried out, and the degassing time is 10 hours.

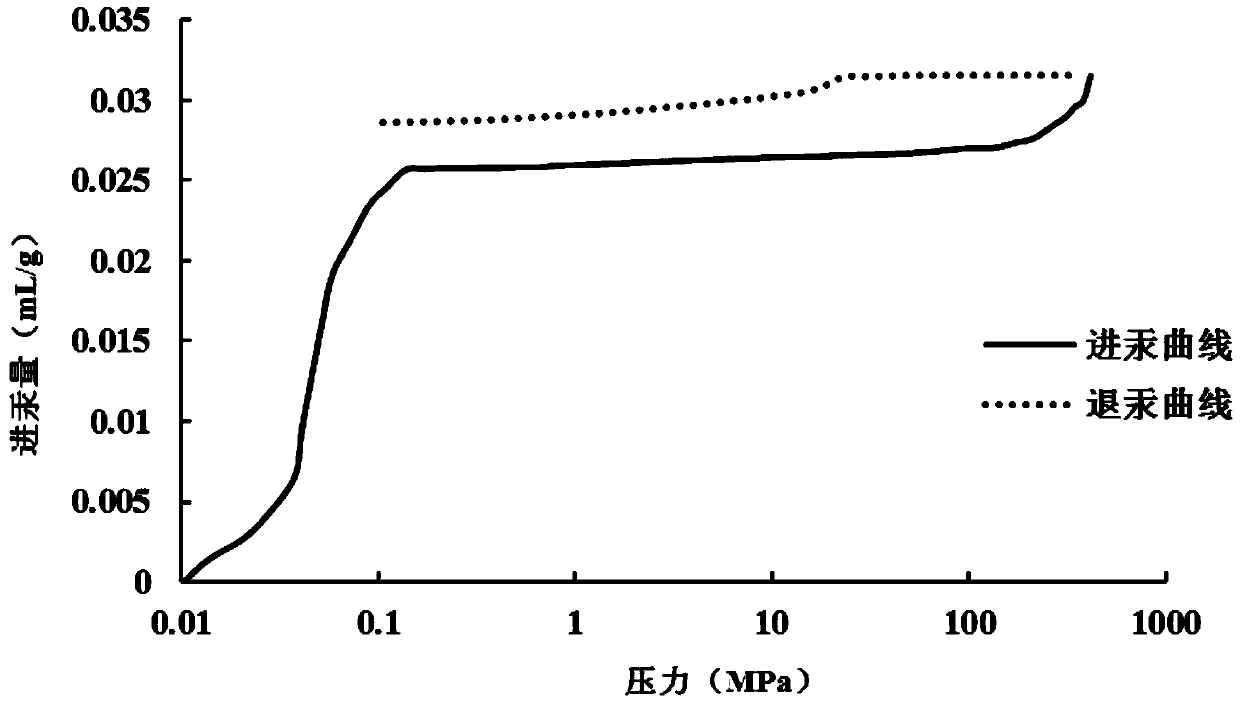

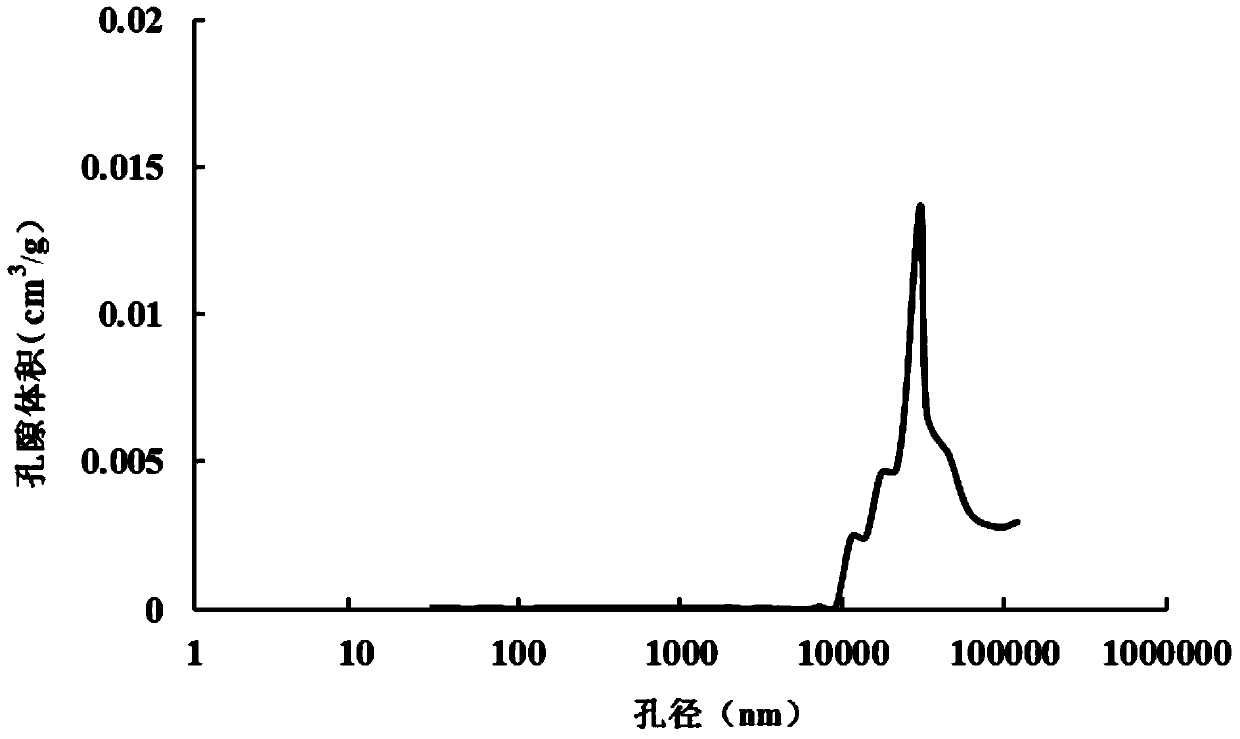

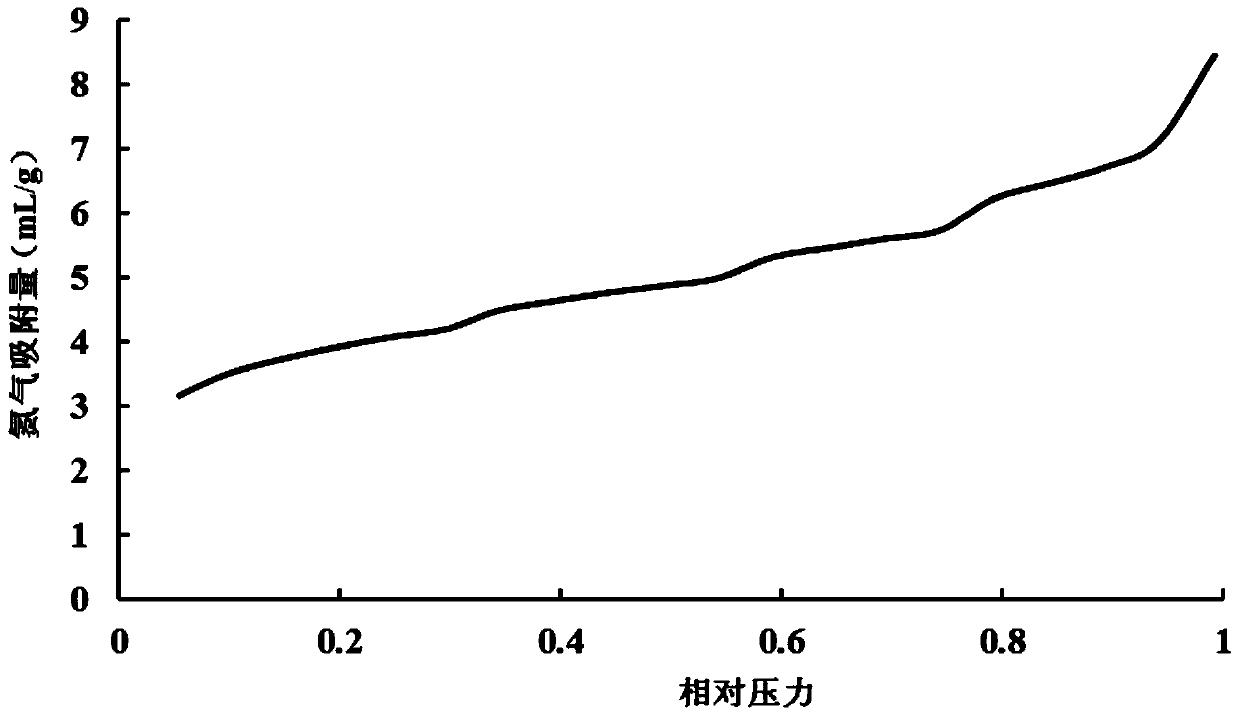

[0046] (3) Sample test: Three independent experiments were carried out on the pretreated samples, namely, high-pressure mercury intrusio...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com