Integral fuel grading supply technology for gas-fired boiler and low-nitrogen gas-fired boiler

A gas-fired boiler and fuel classification technology, which is applied in the field of boiler combustion, can solve the problems of large boiler vibration, low gas fuel utilization rate, and unhelpful gas-fired boilers, so as to suppress the generation of NOX, which is scientifically reasonable and reduces The effect of combustion heat load

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] The present invention will be further described below in conjunction with the accompanying drawings and typical embodiments.

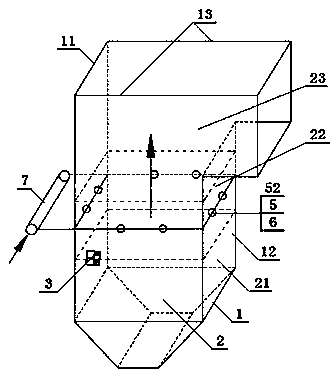

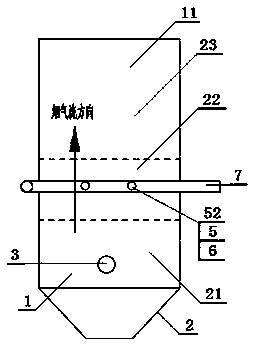

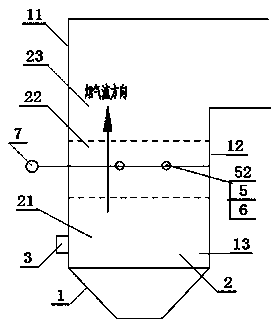

[0022] exist figure 1 , figure 2 , image 3 and Figure 4Among them, the integral fuel staged low-nitrogen gas boiler of the present invention has a main body including a boiler furnace body 1, a boiler furnace chamber 2, a gas burner 3, a combustion-supporting air channel 4 and a gas spray gun 5, and the boiler furnace body 1 includes a front wall 11, The rear wall 12 and the left and right side walls 13 are characterized in that: the furnace chamber 2 of the boiler is sequentially provided with a main combustion zone 21 located upstream in the direction of the flue gas flow and a reburning zone located in the middle stream of the flue gas flow direction. 22 and the burnout area 23 located downstream of the flue gas flow direction; the gas spray gun 5 includes a main supply type gas spray gun 51 and a rear supply type gas spray gun 52; the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com