Floor wax sealing equipment and wax sealing method

A floor and equipment technology, which is applied in the field of floor wax sealing equipment and wax sealing, can solve the problems of lowering the quality of floor products, lowering the waterproof performance of floors, and leakage of wax coating, so as to avoid leakage sealing, improve the effect of wax sealing, and The effect of uniform layer thickness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

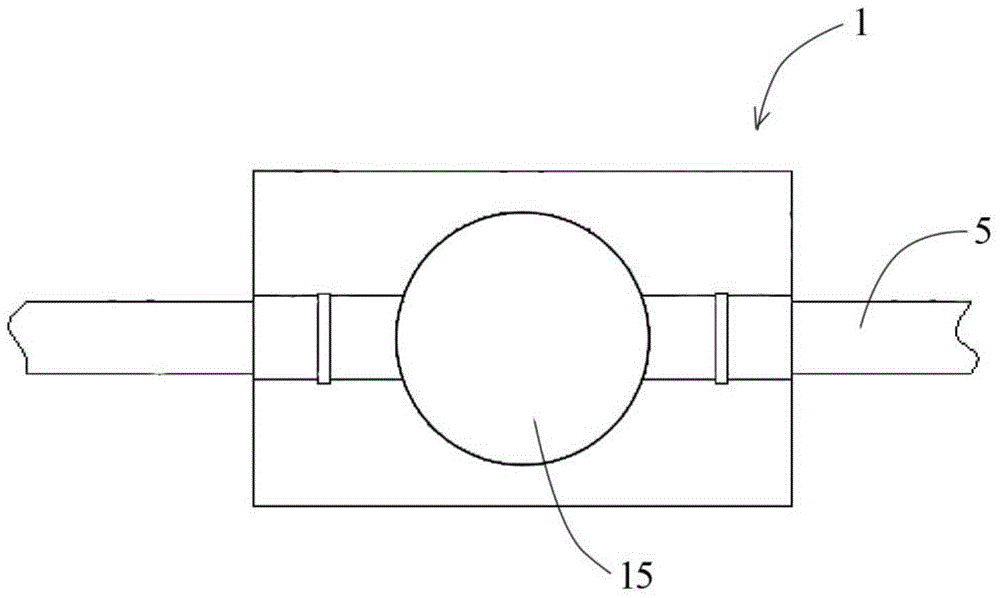

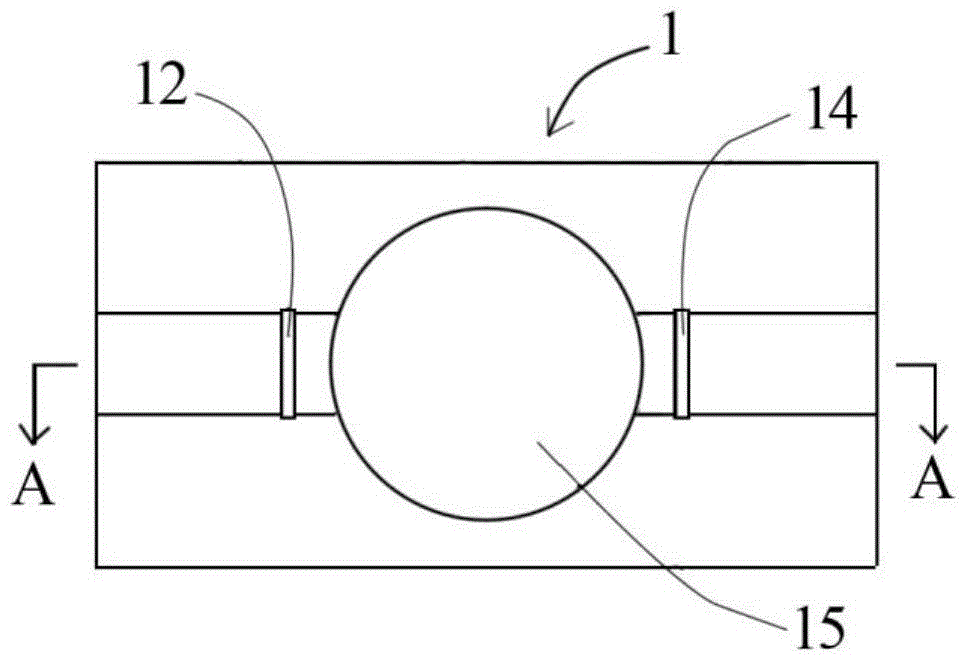

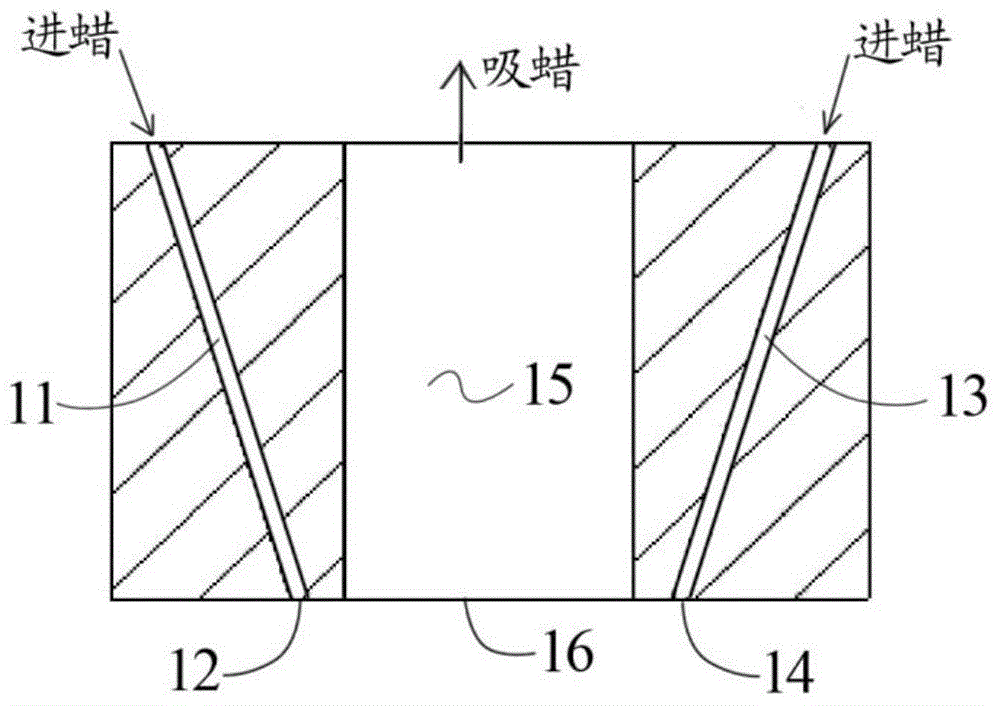

[0031] Figure 1A It is a schematic diagram of matching a sealing wax module with a floor (or called a substrate) according to Embodiment 1 of the present invention, Figure 1B yes Figure 1A A rear view of the sealing wax module shown, Figure 1C yes Figure 1B An A-A sectional view of the sealing wax module shown, Figure 1D yes Figure 1A A left side view of the sealing wax module shown. refer to Figures 1A-1D , the wax sealing module 1 includes a first wax outlet path 11, a second wax outlet path 13 and a wax suction path 15, which will be described respectively below:

[0032] First of all, it should be noted that the "path" in the "wax outlet path" and "wax suction path" mentioned in the present invention can be understood as a channel or a through hole.

[0033] refer to Figure 1B and Figure 1C , the first wax outlet path 11 has a first wax outlet 12 , and the second wax outlet path 13 has a second wax outlet 14 . Moreover, the first wax outlet path 11 and the...

Embodiment 2

[0038] Figure 2A It is a rear view of a sealing wax module according to Embodiment 2 of the present invention, Figure 2B yes Figure 2A The B-B section view. The front view and the sealing wax module provided by the present embodiment Figure 1A The front view of the sealing wax module in is similar and omitted here.

[0039] The sealing wax module 1 provided in this embodiment may have some or all of the technical features of the embodiment shown in FIG. 1 , and may also have some or all of the following technical features.

[0040] refer to Figure 2A and Figure 2B , The wax suction path 15 as a whole can be a circular channel with a diameter of Φ of 40mm-50mm, of course, it can also be an oval or other shaped channel. The first wax outlet path 11 and the second wax outlet path 13 are generally rectangular channels with a height h of 15mm and a width m of 2mm. Of course, they can also be rectangles, rounded rectangles or other specifications (for example: 14mm×2.2mm)...

Embodiment 3

[0045] Figure 3A It is a front view of a damping device of a wax sealing device according to Embodiment 3 of the present invention, referring to Figure 3A , The damping device 3 includes a roller 31 , a roller positioning mechanism 32 and a damping mechanism 33 . The following is a detailed description:

[0046] The roller 31 has elastic deformation ability, or more specifically, the rolling surface portion of the roller 31 can be elastically deformed, for example, the roller 31 can be a PU roller made of polyurethane (Polyurethane, PU). The rollers 31 are used to contact the floor 5 to apply pressure to the floor 5 so as to eliminate horizontal shaking of the floor in the advancing (transporting) direction.

[0047] The roller positioning mechanism 32 is used to locate the roller 31 in the horizontal direction and make the roller 31 have the ability to rotate freely, therefore, the roller 31 can rotate with the transmission of the floor.

[0048] The damping mechanism 33...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Texture depth | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com