Suspending chain type ultrasonic automatic cleaning machine suitable for cleaning of cylinder sleeve

An automatic cleaning machine and ultrasonic technology, applied in the direction of using liquid cleaning methods, cleaning hollow objects, cleaning methods and utensils, etc., can solve the problems of heavy load, difficult maintenance, and high labor intensity of the cleaning machine

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

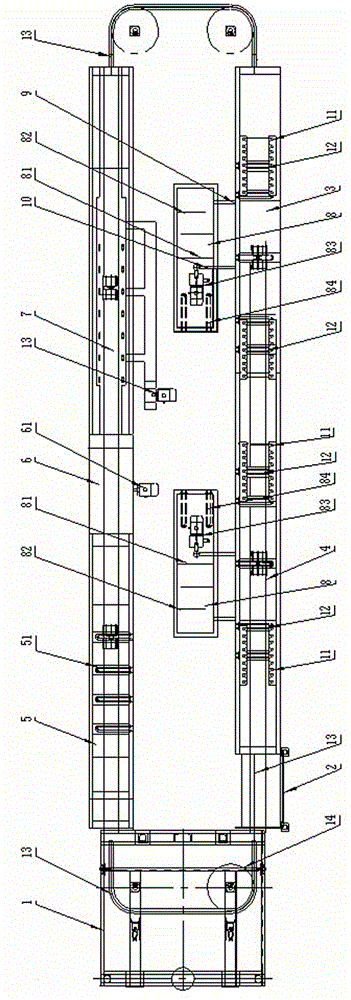

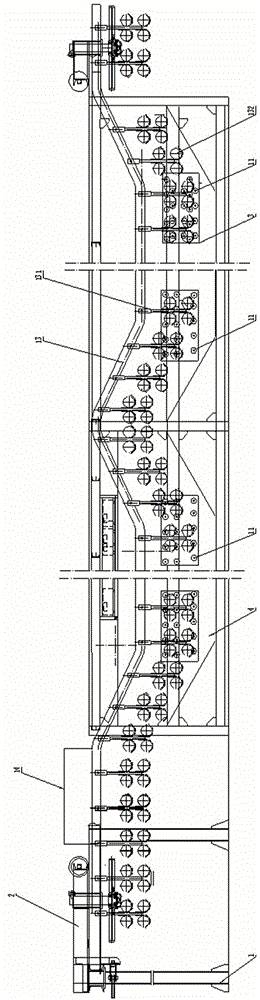

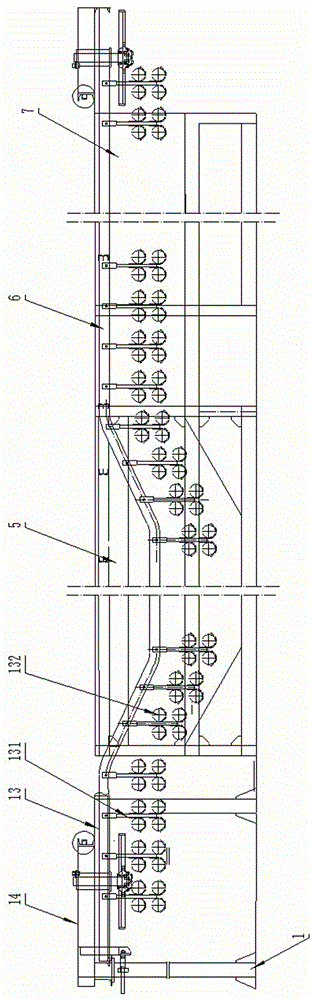

[0013] The hanging chain type ultrasonic automatic cleaning machine suitable for cleaning cylinder liners of the present invention will be described in further detail below in conjunction with the accompanying drawings.

[0014] Depend on figure 1 , figure 2 , image 3 It can be seen that the suspension chain type ultrasonic automatic cleaning machine suitable for cleaning cylinder liners of the present invention includes a frame 1, a tensioning device 14 and a transmission device 2 are installed on the frame 1, and the transmission device 2 includes a suspension Chain 13, ultrasonic cleaning tank 3, ultrasonic rinsing tank 4, bubbling scalding tank 5, drying chamber 6 and closed drying box 7 are also installed on the frame 1, ultrasonic cleaning tank 3 and ultrasonic rinsing tank 4 Ultrasonic cleaning liquid storage tank 8 is installed above; Wherein, the both sides of described ultrasonic cleaning tank 3 are equipped with several ultrasonic vibrating plates 11, and ul...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com