Metal sheet bending machine

A metal sheet and bending machine technology, applied in the field of automated production equipment, can solve the problems of difficulty in ensuring the accuracy of manual operations, low efficiency, and prone to operational accidents, and achieve the effects of improving production efficiency, low machine cost, and compact coordination

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

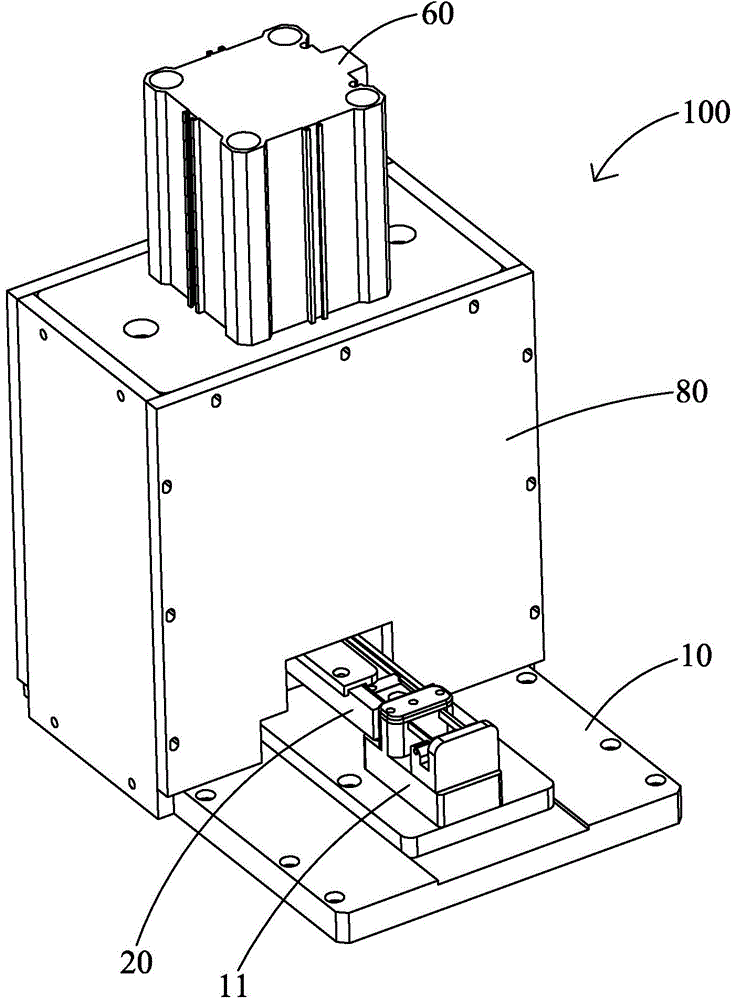

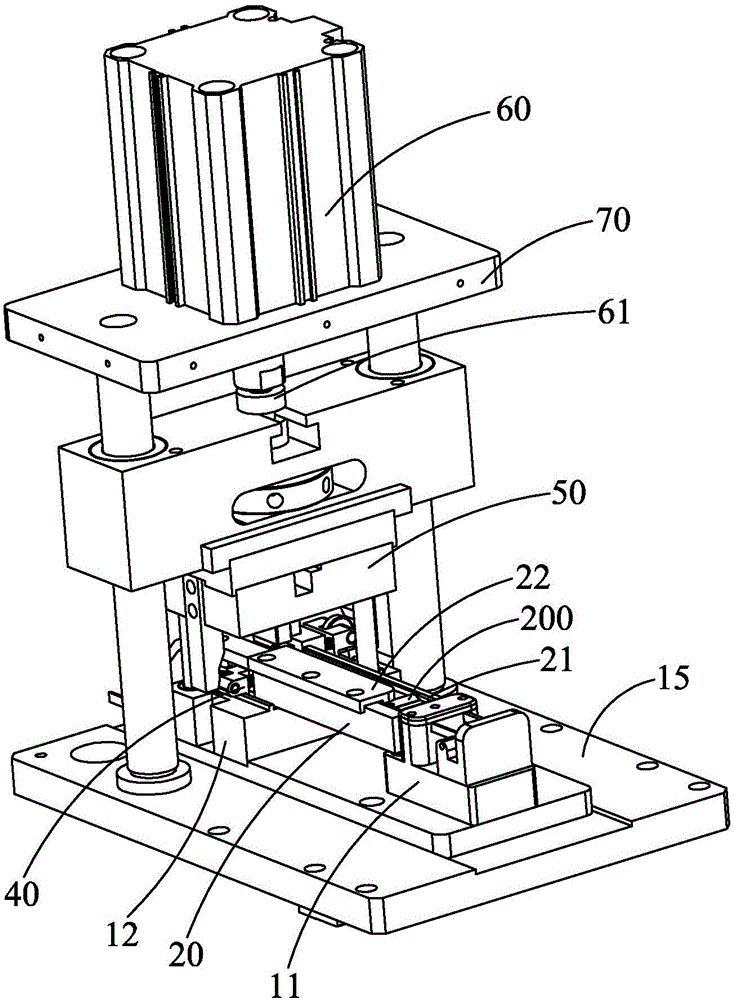

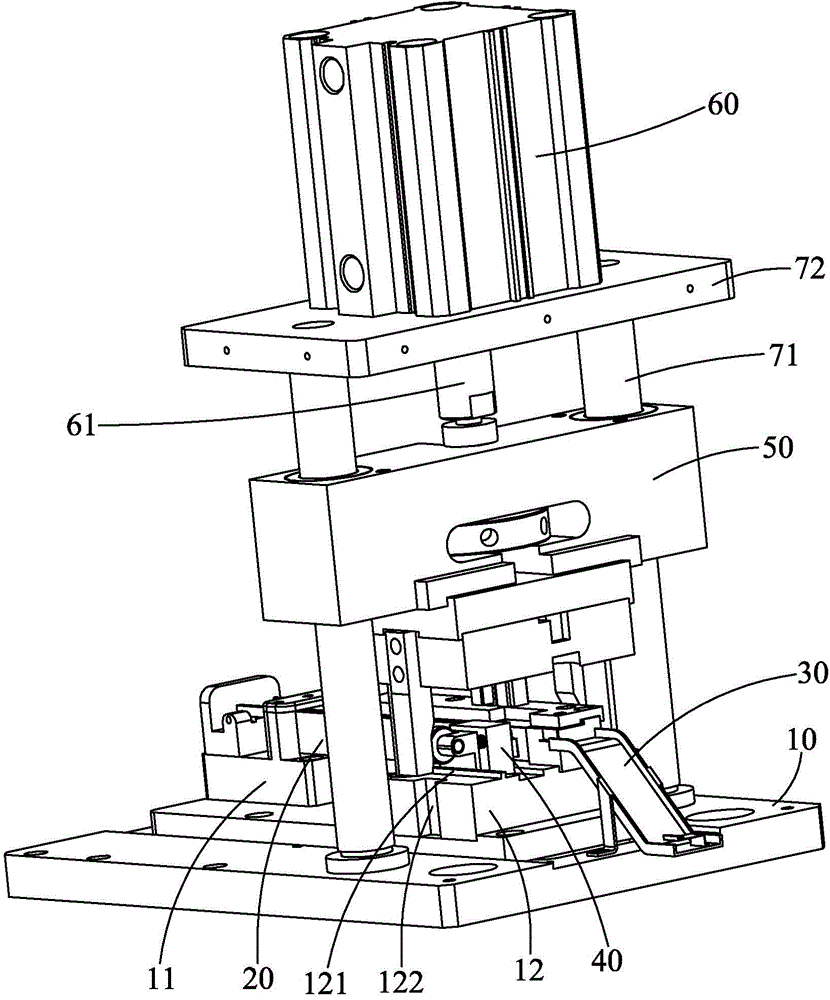

[0015] see Figure 1 to Figure 6 As shown, the sheet metal bending machine 100 of the present invention is used to bend the sheet metal 200 so that the sheet metal 200 has two bending portions 201 , 202 , namely the first bending portion 201 and the second bending portion 202 . The metal sheet bending machine 100 includes a machine base 10, a feed slide rail 20, a discharge slide rail 30, a bending assembly 40, a slide assembly 50, a cylinder 60 for driving the slide assembly 50 to move up and down, and a bracket for fixing the cylinder 60. 70, and the machine cover 80 that is provided on the outside of the bending assembly 40 and the sliding assembly 50. The machine cover 80 can prevent dust from entering the sheet metal bending machine 100 . The feeding slide rail 20 , the discharging slide rail 30 and the bending assembly 40 are respectively arranged on the machine base 10 .

[0016] The machine base 10 includes a platform 15 and first and second bases 11 and 12 spaced ap...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com