Single punch automatic production line

A technology of automatic production line and punching machine, applied in the direction of manipulator, metal processing equipment, feeding device, etc., can solve the problems of low production efficiency, high labor intensity of workers, hidden danger of stamping production safety, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

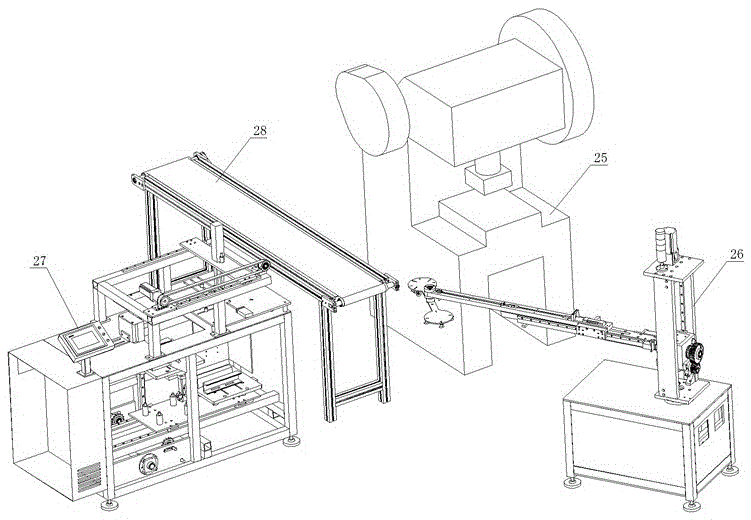

[0025] Such as figure 1 As shown, the single-press automatic production line of the present invention is made up of stamping equipment 25, single-arm multi-axis manipulator 26, automatic feeding device 27 and discharge platform 28, and the automatic feeding device provides a single iron plate, single-arm multi-axis The manipulator performs reciprocating swings, advances and retreats, rotations, lifts and flips between the automatic feeding device, stamping equipment and the discharge conveyor.

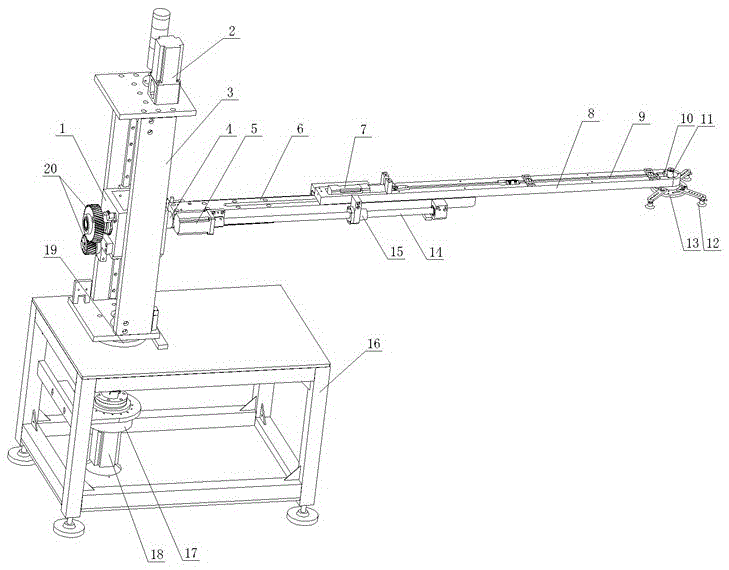

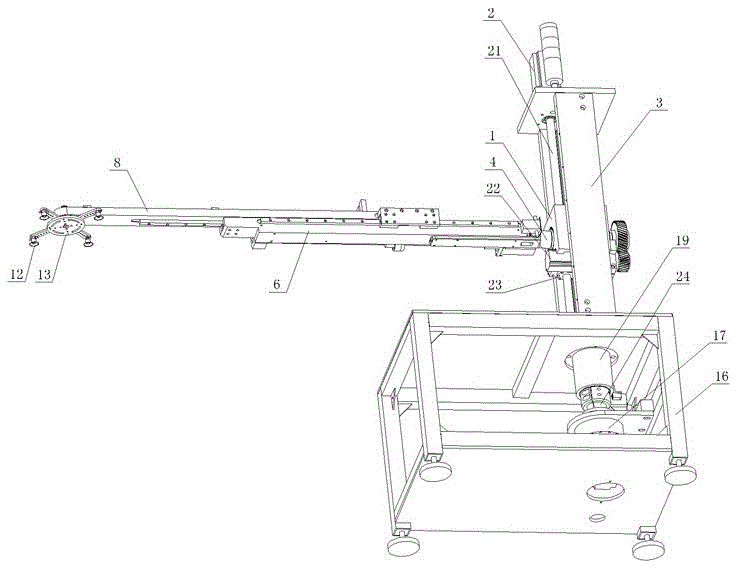

[0026] Such as figure 2 , 3 As shown, the single-arm multi-axis manipulator includes a first frame 16 and a mechanical arm located on the first frame 16. The mechanical arm is placed horizontally. The mechanical arm is composed of a forearm 8 and a rear arm 6. The forearm 8 Slidingly arranged on the rear arm 6, it can be driven forward or backward by the advance and retreat motor 5, and the advance and retreat motor 5 is installed on the rear arm 6. The motor shaft of the motor 5 i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com