A fully automatic punch synchronous sheet conveying mechanism

A synchronous transmission and fully automatic technology, which is applied in the direction of metal processing equipment, feeding devices, manufacturing tools, etc., can solve the problems of the mechanism not working normally, the sheet is stuck on the fixed plate, and the transmission speed is slow, so as to achieve the sheet pushing process Simple and straightforward, stable work and compact structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

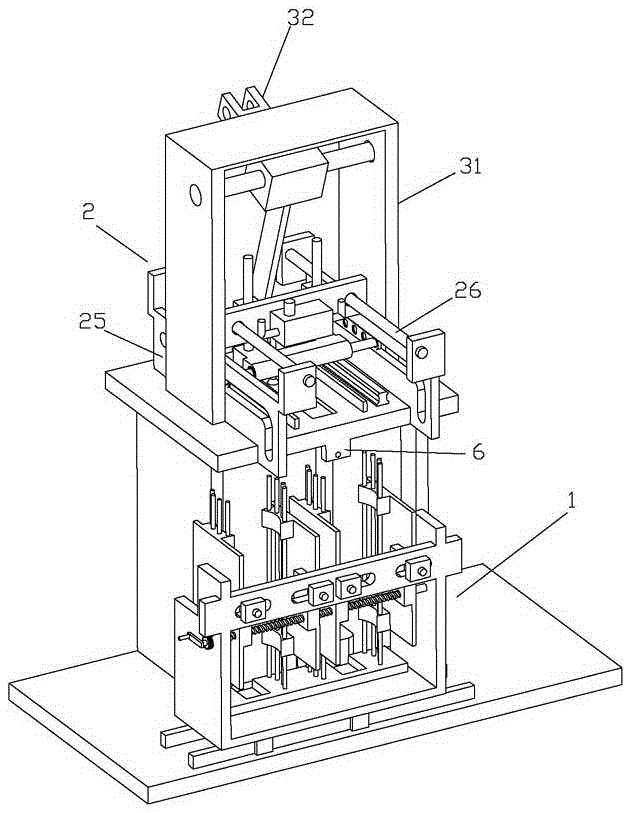

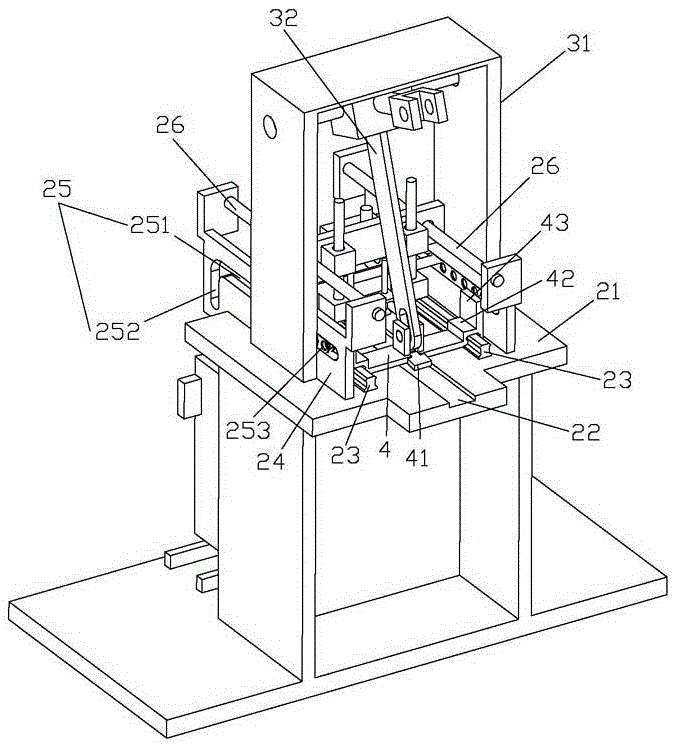

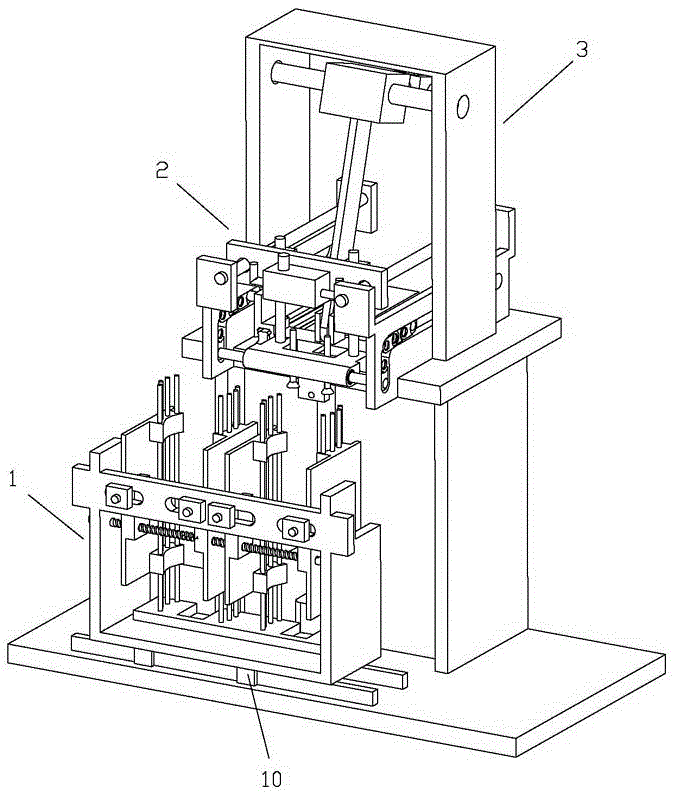

[0018] Such as Figure 1-6 As shown, a synchronous transmission mechanism for a fully automatic sheet punching machine includes a sheet feeding mechanism 1 and a sheet pushing mechanism 2. The sheet feeding mechanism 1 is placed at the rear end of the sheet pushing mechanism 2, and is characterized in that: the sheet pushing mechanism 2 includes a bottom plate 21 , the base plate 21 is provided with a synchronous drive mechanism, the synchronous drive mechanism 3 includes a bracket 31, a rocker arm 32 and a connecting rod, the bracket 31 is installed on the base plate 21, the rocker arm 32 is pivotally connected to the bracket 31, and the connecting rod One end is hinged with the upper arm of the rocking arm 32, and the other end is connected with the driving device of the punch press. The lower arm of the rocking arm 32 is hinged with the middle of the slider device; The rear portion of the groove 22 is also provided with a stop bar; the both sides of the push piece groove 22...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com