A preparation method for cut-to-length shearing of differential thickness plate

A technology of fixed-length shearing and thickness difference, which is applied in the direction of shearing device, shearing machine equipment, shearing machine control device, etc., can solve the problem of not being able to identify the shape and size of the PLP strip, and achieve the effect of high-precision cutting

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

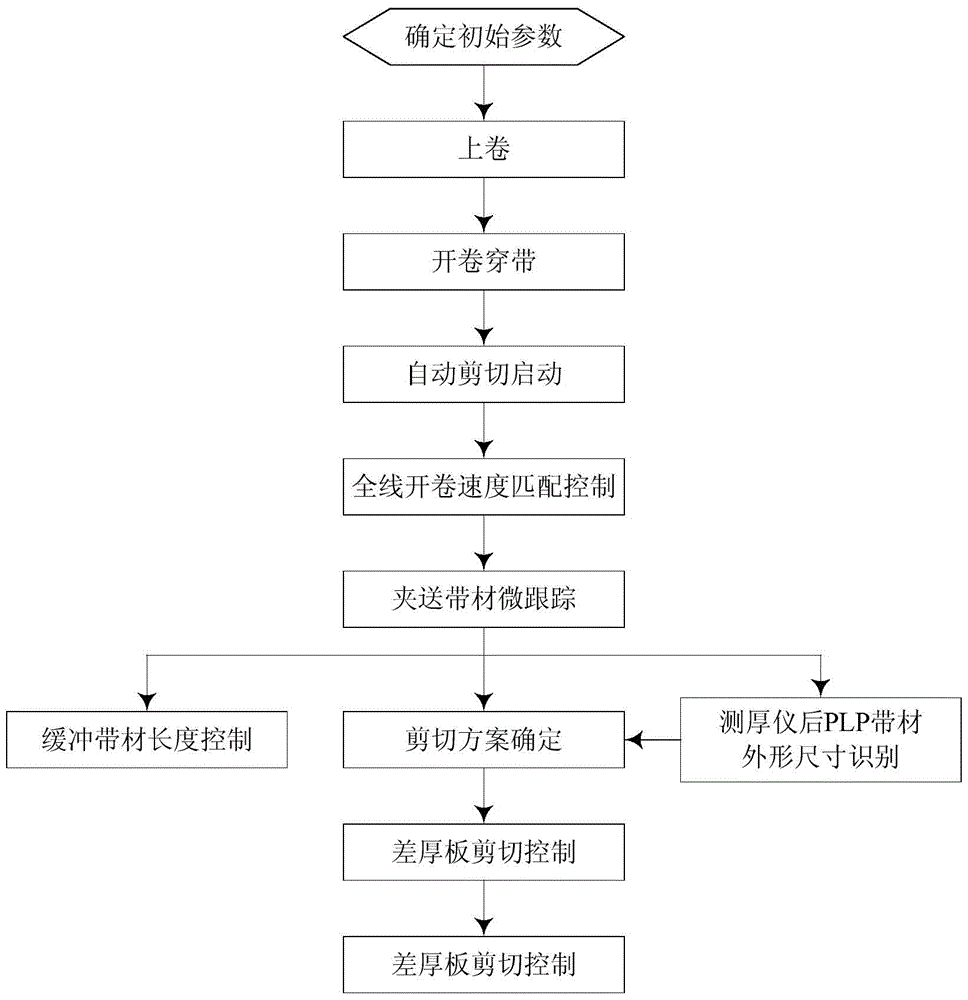

[0051] Such as figure 1 Shown, a kind of difference thick plate cut-to-length preparation method, comprises the following steps:

[0052] Step 1: Determine the initial shear parameters of the differential thick plate, including the target differential thick plate external dimension parameters, PLP strip coil diameter, shear speed, buffer pit buffer strip length, etc.

[0053] Step 2: The annealed PLP strip is coiled and uncoiled on an uncoiler.

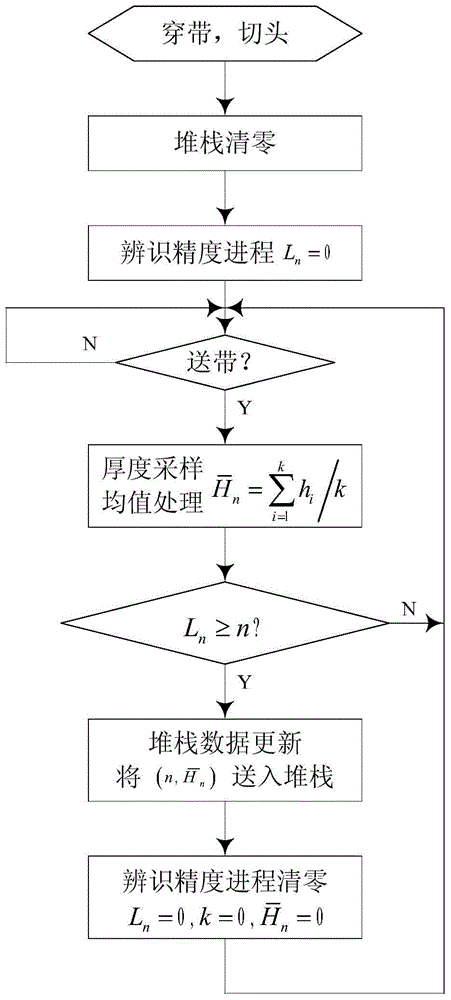

[0054] Step 3: The uncoiler is uncoiled and jogged, and the pinch roller before straightening, the straightener, the thickness gauge, the thickness gauge, the pinch roller before shearing, and the hydraulic shear are sequentially threaded, and the pinch rollers are pressed in sequence Strip. The micro tension is established by the uncoiler to make the strip tight and straight, and the hydraulic shear cuts the strip head;

[0055]Step 4: Start automatic cutting. The uncoiler automatically uncoils, the computer control system starts...

Embodiment 1

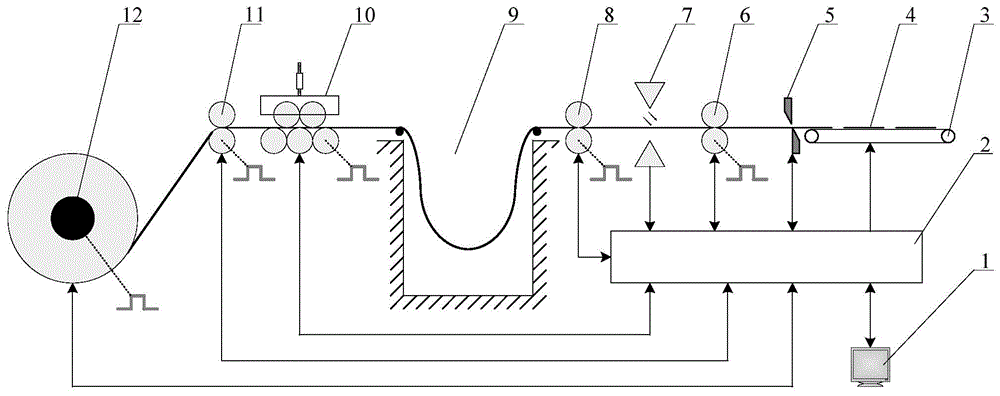

[0096] The relevant parameters of the system of the present invention are as follows:

[0097] The maximum coil diameter of the uncoiler is 2200mm, and the minimum coil diameter is 560mm; the power of the main motor of the five-roller straightening machine is 18.5kW; the distance between the thickness gauge and the shear line is L 0 =2500mm, the thickness gauge is an X-ray thickness gauge, the measurement range is 0.1-5.0mm, the static accuracy 2σ=±0.10%, the repeatability is ±0.05%, the long-term stability is ±0.05% / 8h; each incremental code The single-turn pulse of the device is 1000. Cutting line feeding speed setting: 0.5m / s.

[0098] Target difference thick plate size: thick zone thickness 1.2mm, length 300mm; transition zone length 50mm; thin zone thickness 0.8mm, length 300mm.

[0099] Actual shearing accuracy: the total error of the cycle length is <±1mm, and the shearing accuracy of the head and tail is less than ±0.5mm.

Embodiment 2

[0101] The relevant parameters of the system of the present invention are as follows:

[0102] The maximum coil diameter of the uncoiler is 2200mm, and the minimum coil diameter is 560mm; the power of the main motor of the five-roller straightening machine is 18.5kW; the distance between the thickness gauge and the shear line is L 0 =2500mm, the thickness gauge is an X-ray thickness gauge, the measurement range is 0.1-5.0mm, the static accuracy 2σ=±0.10%, the repeatability is ±0.05%, the long-term stability is ±0.05% / 8h; each incremental code The single-turn pulse of the device is 1000. Cutting line feeding speed setting: 0.5m / s.

[0103] Target difference thick plate size: thick zone thickness 1.5mm, length 200mm; transition zone length 100mm; thin zone thickness 0.8mm, length 200mm;

[0104] Actual shearing accuracy: the total error of the cycle length is <±1mm, and the shearing accuracy of the head and tail is less than ±0.5mm.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com