Processing tooling for external circle of tube stock

A technology for pipe cylindrical processing and tooling, which is applied in the direction of metal processing equipment, metal processing machine parts, positioning devices, etc., can solve problems such as broken iron stops, time-consuming and labor-intensive problems, and achieve improved support capacity, improved work efficiency, and reduced manual operations Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0014] The present invention will be further described below in conjunction with accompanying drawing;

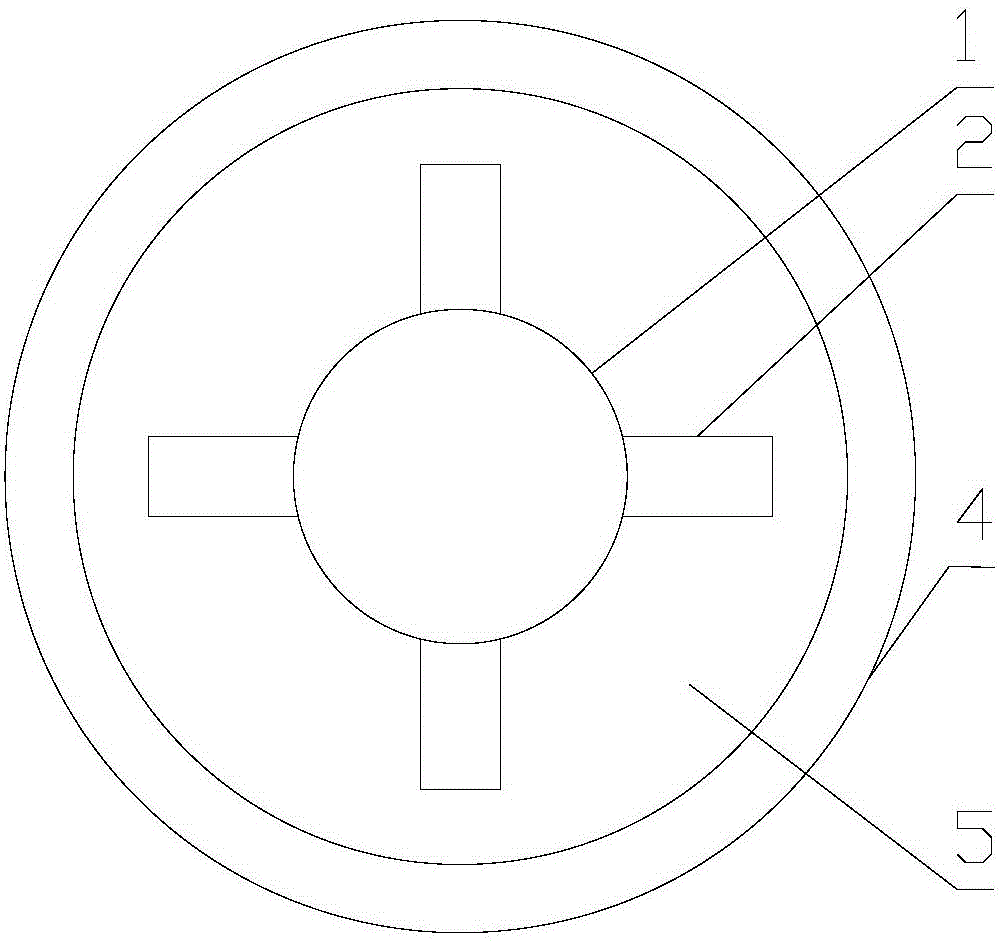

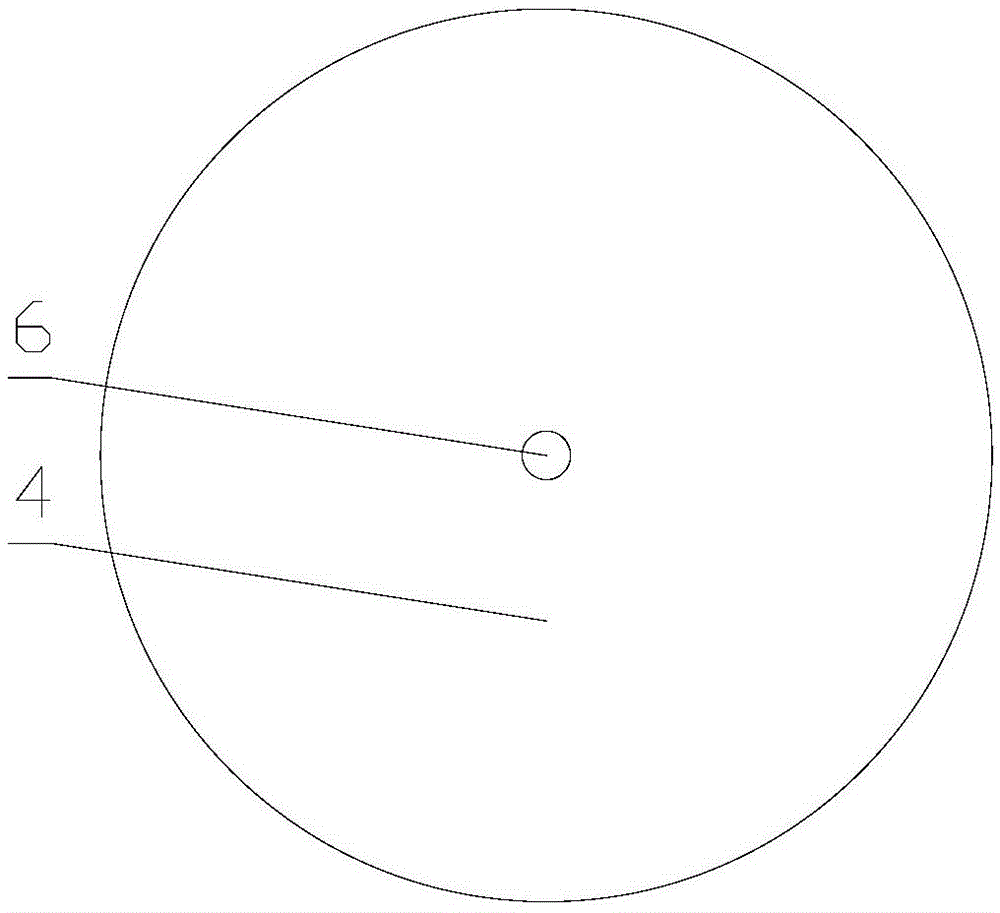

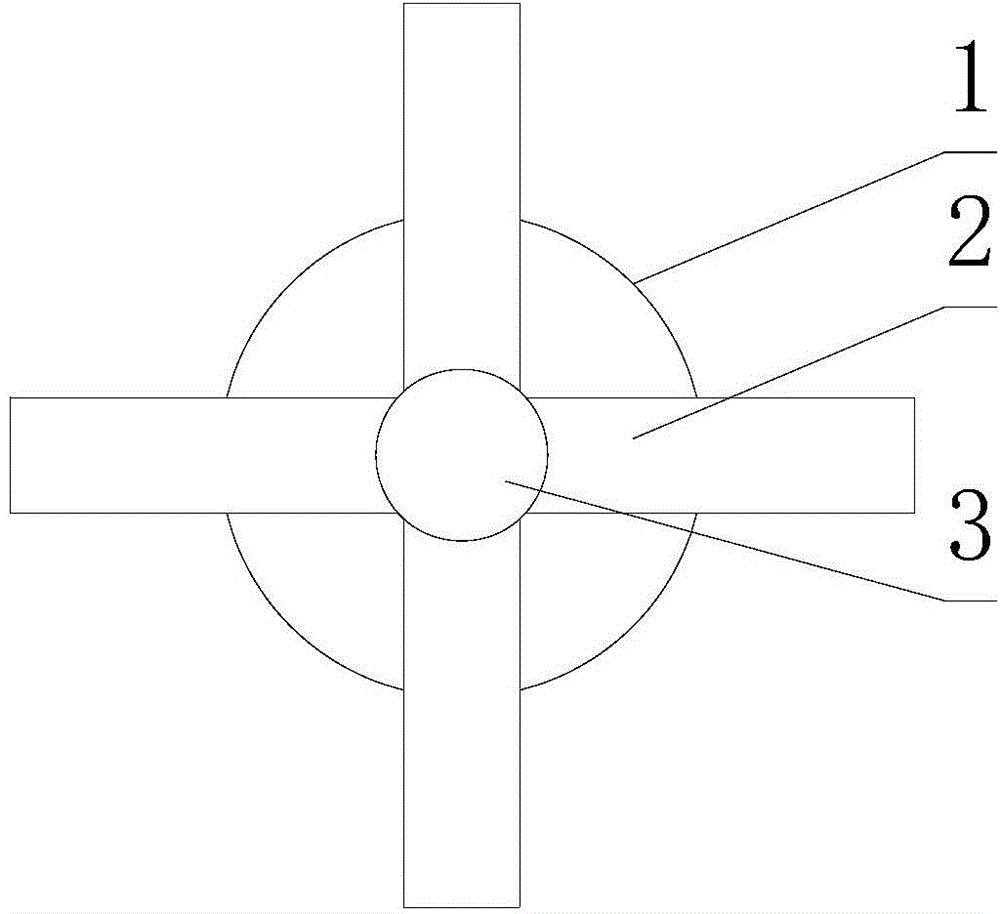

[0015] see Figure 1-4 A pipe outer circle processing tool is shown, including a disc 1 and a stopper 4 welded together with the disc 1. The disc 1 is provided with a cylinder 3 and a telescopic rod 2, and the side of the disc 1 is evenly distributed with multiple A through hole 7 for telescopic rod 2 is provided, and a center hole 6 matching with the taper of the lathe tip is provided at the center of the iron stopper 4 .

[0016] The middle part of the iron stopper 4 is provided with a boss 5, and the boss 5 is a circle suitable for the inner diameter of the centrifugal cast iron pipe.

[0017] The number of the telescopic rods 2 is at least three.

[0018] When finishing, one end of the centrifugal cast iron pipe is first connected to the chuck, and the other end is connected to the thimble of the lathe through the above-mentioned tooling. Start the cylinder 3, adjust...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com