External permanent magnet motor direct-driven roller structure of rubber refiner

A permanent magnet motor and refiner technology, applied in the fields of rubber refiner and rubber refiner roller drive, can solve the problems of low work efficiency, large heat loss of mechanical loss motor, etc., achieve beautiful appearance, reduce floor space, The effect of reducing mechanical loss

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

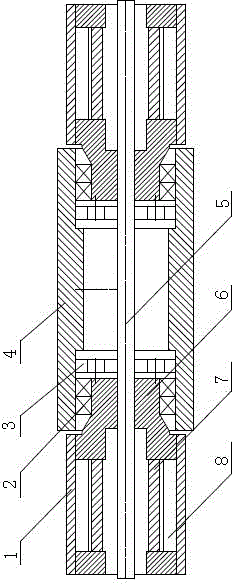

[0009] The rubber refining machine of the present invention has an external permanent magnet motor direct drive roller structure as follows: figure 1 As shown, the two ends of the roller 4 are fixedly connected to the permanent magnet motor casing 1 through the supporting connecting shaft 6, and a pair of driving gears 3 are installed inside the roller 4 at the inner sides of the supporting connecting shaft 6, and the intermediate driving shaft 5 runs through the permanent magnet motor, Support connecting shaft 6, gear 3 and roller 4 centers, permanent magnet motor shaft and roller center shaft 5 structure of intermediate drive shaft integrated, between supporting connecting shaft 6 and roller 4 shells, rolling bearing 2 is arranged. Both sides of the roller 4 are external permanent magnet motors, the permanent magnet motor shell 1 is used as a fixed bearing seat for driving the roller 4, and the permanent magnet motors on both sides drive the permanent magnet motor rotor 8 out...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com