Large-scale sliding block structure for preventing product from burring

A burr and large-scale technology, applied in the field of large-scale slider structure, can solve the problems of burrs and gaps in products

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

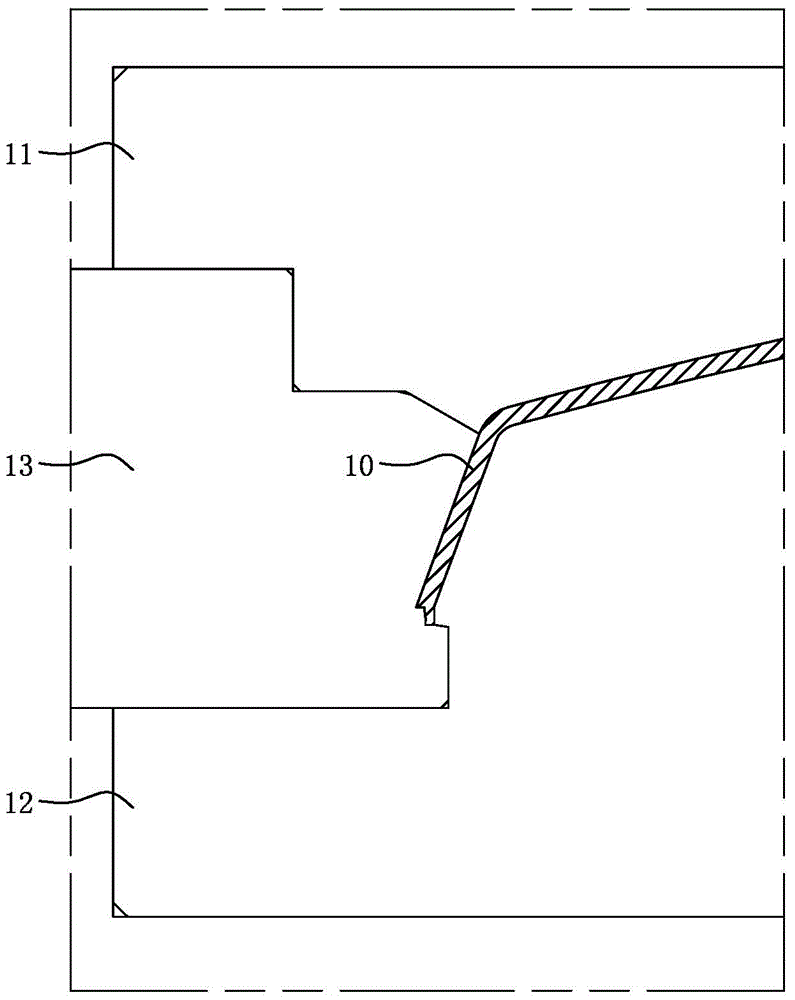

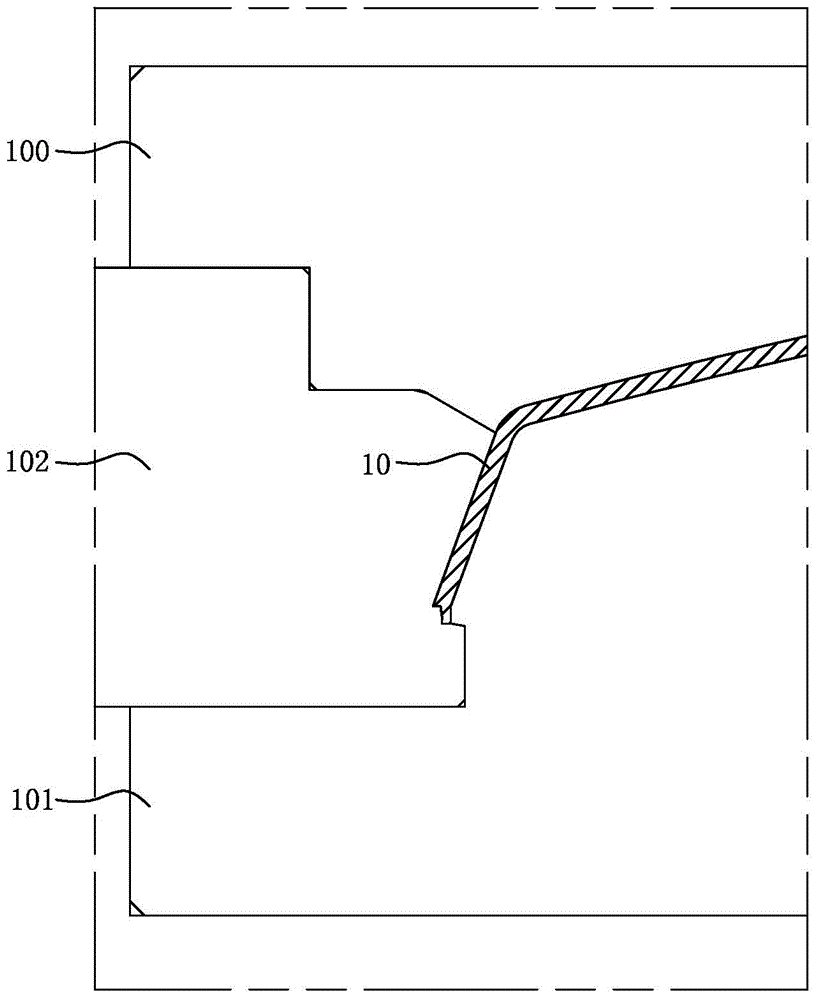

[0017] Please refer to figure 1 , image 3 , image 3 It is a structural schematic diagram of a preferred embodiment of the large-scale slider structure for preventing product burrs according to the present invention.

[0018] In order to achieve the above purpose, the present invention provides a large-scale slider structure that prevents the product from burrs. The formed product 10 has a larger entire surface. The structure includes:

[0019] Master core 100;

[0020] The male mold core 101 is combined with the female mold core 100 to form the product 10;

[0021] The large slider 102 is set between the male mold core 101 and the female mold core 100 to form a larger entire surface of the product 10, and there is an insertion part between the large slider 102 and the male mold core 101. Die face.

[0022] Wherein, the gap between the large slider 102 and the male mold core 101 during injection molding is relatively small, for example less than 0.03 mm, so that liquid p...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com