A composite safety glass made with a multilayer thermoplastic polymer interlayer film

A thermoplastic polymer, safety glass technology, applied in glass/slag layered products, layered products, synthetic resin layered products, etc. Achieve the effect of reducing the probability of inner glass breaking, improving impact resistance and reducing impact resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

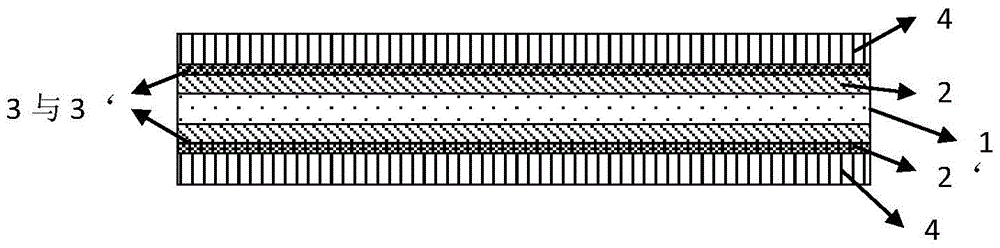

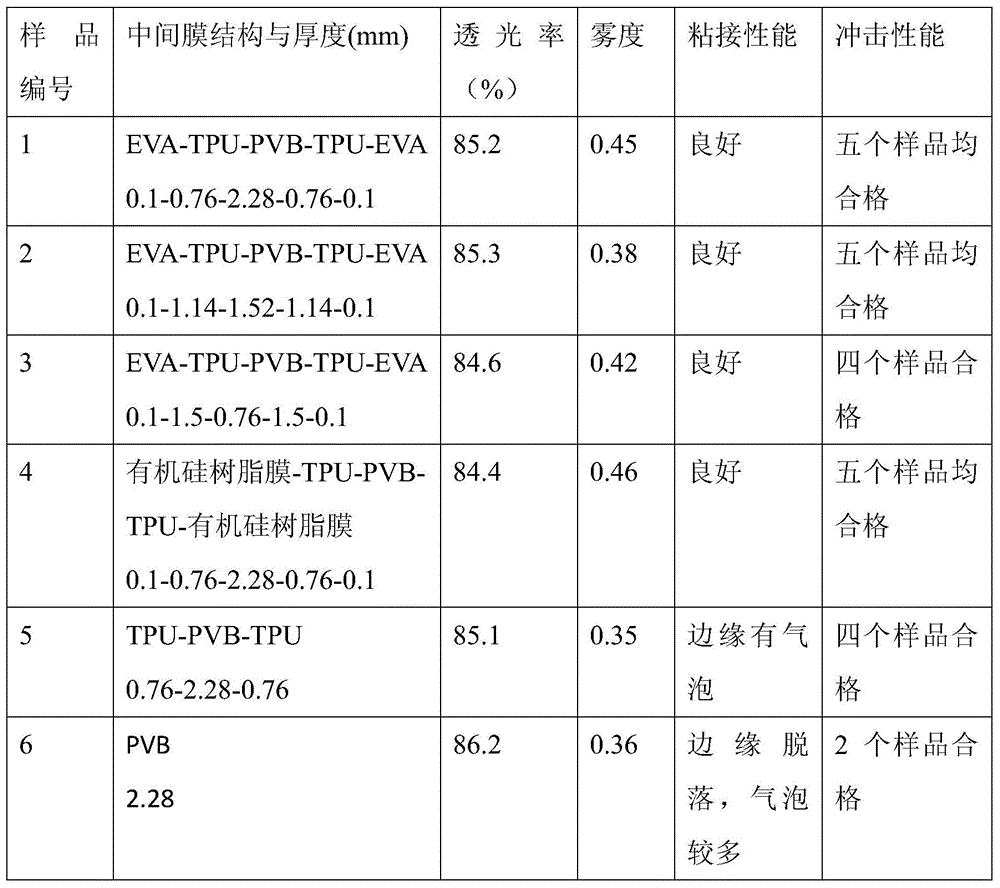

[0026] On a flat plate, the size of chemical tempered glass is 2.5mm, 0.1mm thick EVA resin film, 0.76mm thick TPU film, 2.28mm thick hard PVB film, 0.76mm thick TPU film, 0.1mm thick EVA resin film and 2.5 mm chemically tempered glass. Place the laminated sample in a vacuum bag, seal the opening of the vacuum bag with adhesive tape, turn on the vacuum pump to evacuate the vacuum bag, and the vacuum degree is 0.03MPa. The vacuum bag is placed in an autoclave, the temperature is controlled at 120-135 ° C, the system pressure is 0.5-1.0 MPa, and the heating and pressurization is maintained for 1 hour. After the heating and pressurization was stopped, the samples were naturally cooled and taken out for testing.

Embodiment 2

[0028] According to the method of Example 1, the lamination and hot pressing processes are carried out. Just change the TPU film to 1.14mm here, and replace the middle PVB hard film to 1.52mm, keep other parameters unchanged, and prepare samples;

Embodiment 3

[0030] According to the method of Example 1, the lamination and hot pressing processes are carried out. Just change the TPU film to 1.5mm here, and replace the middle PVB hard film to 0.76mm, keep other parameters unchanged, and prepare samples;

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com