Bag pressing shaper

A technology of shaping machine and shaping roller, applied in packaging and other directions, can solve the problems of shortened service life of the chain, long driving stroke of the chain, low driving efficiency of the motor, etc., and achieves the effect of uniform force, convenient assembly and installation, and reduction of transmission jitter.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

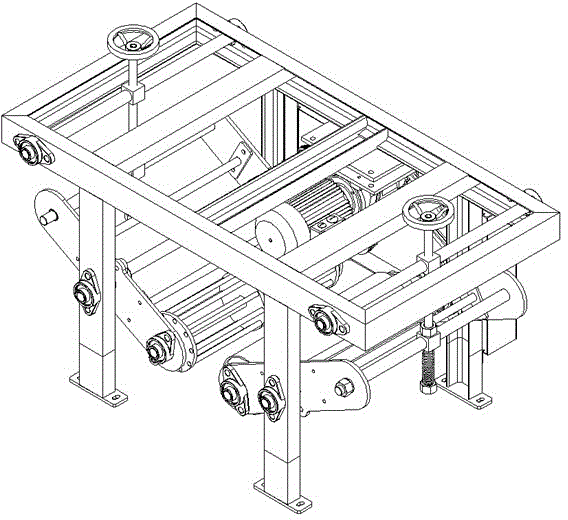

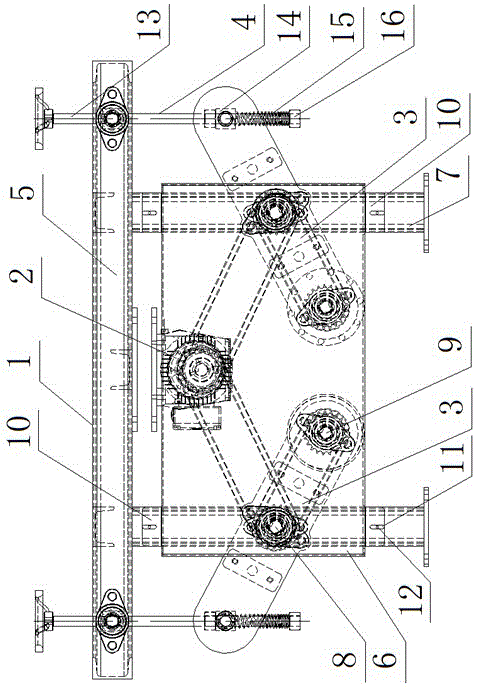

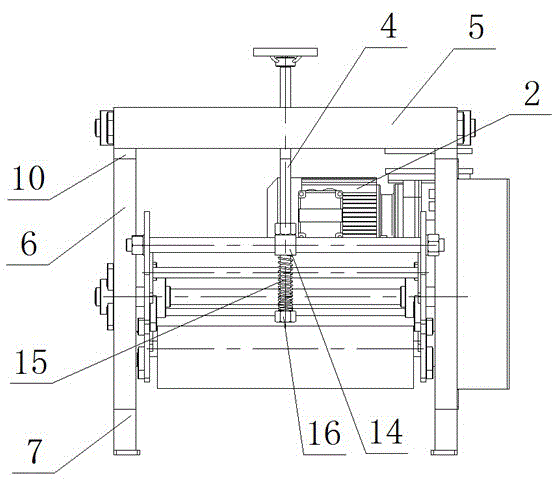

[0017] As shown in the figure, a pressing bag shaping machine includes a frame 1, a motor 2, a shaping roller 3 and a shaping roller height adjustment device 4; the frame 1 includes an upper connecting frame 5, a lower connecting frame 6 and a supporting leg 7 ; The lower connecting frame 6 is provided with a motor 2 and a shaping roller 3, and the shaping roller 3 is provided with a driving sprocket 8 and a driven sprocket 9, and the driving sprocket 8 and the driven sprocket 9 are connected by a chain, and the driving chain Wheel 8 is connected with motor 2 by a chain. The motor 2 is arranged in the middle part of the lower connecting frame 6, and the lower connecting frame 6 is symmetrically provided with two groups of shaping rollers 3, and the two groups of shaping rollers 3 are respectively connected with the motor 2; the driving sprocket 8 is arranged in the middle part of the shaping roller 3, and the driven chain Wheel 9 is located at the bottom of shaping roller 3 . ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com