A plastic trash can

A technology for garbage baskets and plastics, which is used in trash cans, garbage collection, household appliances, etc., can solve the problems of odorous gas, prone to sharp corners, mildew and rot, etc., to avoid the generation of odorous gas, reduce production costs, and reduce The effect of work difficulty

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

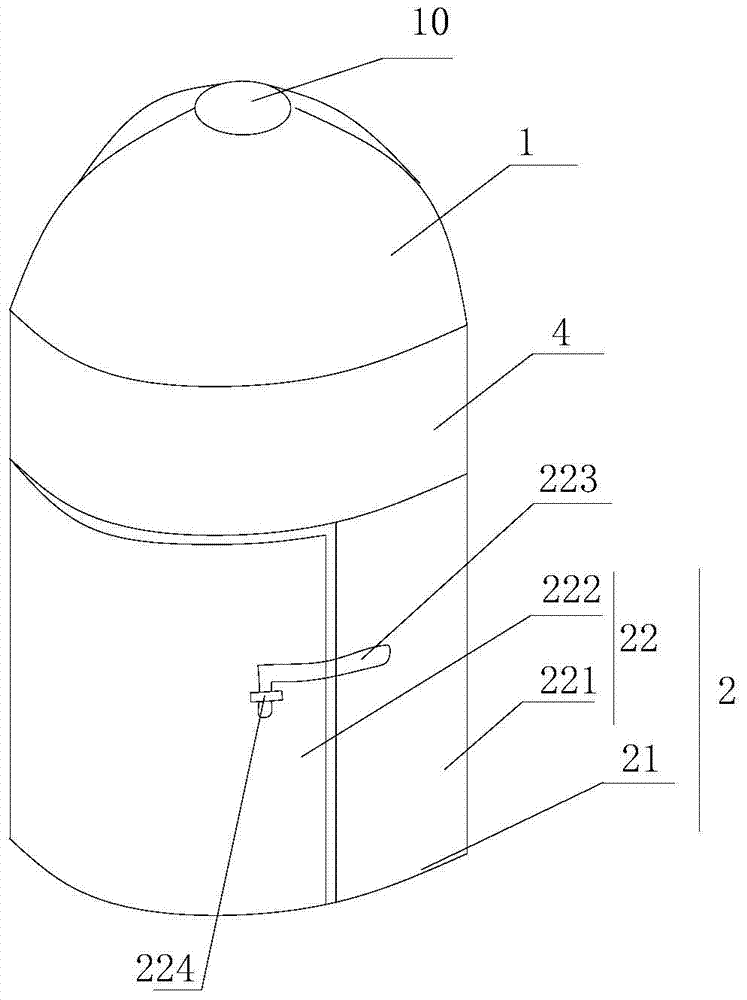

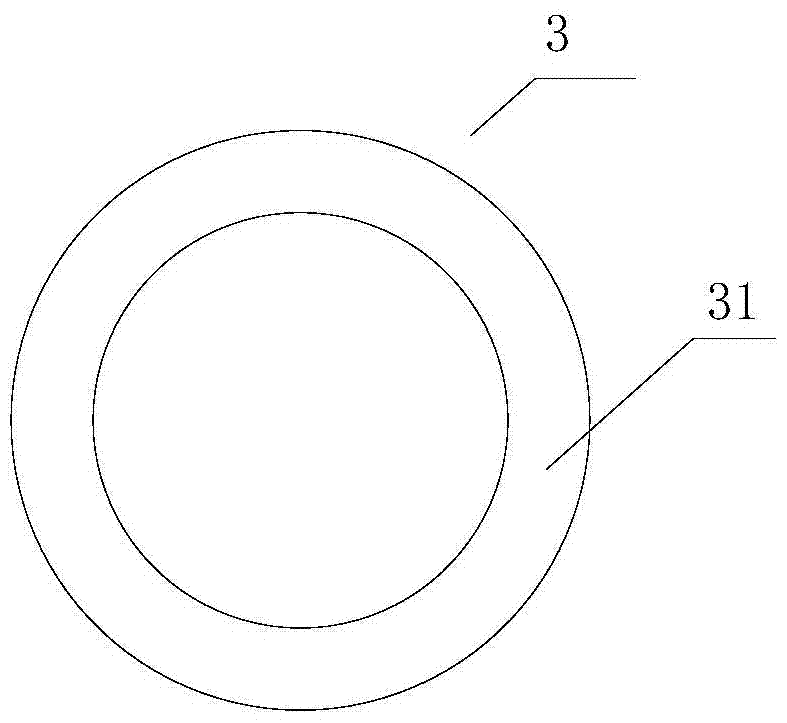

[0022] refer to figure 1 , figure 2 , a kind of plastic weaving garbage basket proposed by the present invention comprises: an upper end 1 , a middle end 4 , a lower end 2 and a waste water recovery bucket 3 . The upper end 1, the middle end 4 and the lower end 2 are all made of soft plastic.

[0023] The upper end 1 is a vertically interconnected structure formed by a plurality of hollow circles arranged coaxially from top to bottom with successively increasing diameters. The upper end surface of the upper end 1 is provided with a first opening 10 for throwing in garbage.

[0024] The lower end portion 2 is composed of a bottom surface 21 and a surrounding wall 22 , and the middle end portion 4 is an annular wall whose projection on a horizontal plane coincides with the outer circumference of the bottom surface 21 . The projection of the lower end surface of the upper end portion 1 and the surrounding wall 22 on the bottom surface 21 also coincides with the outer periphery...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com