Unidirectional braking die forging chain on clinker chain bucket conveyor

A one-way braking and conveyor technology, which is applied in the direction of conveyor, transportation and packaging, etc., can solve the problems of heavy overall weight of the conveyor chain, high energy consumption, and low safety performance, and achieve uniform strength distribution and low energy consumption. The effect of reducing and improving the safety factor

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

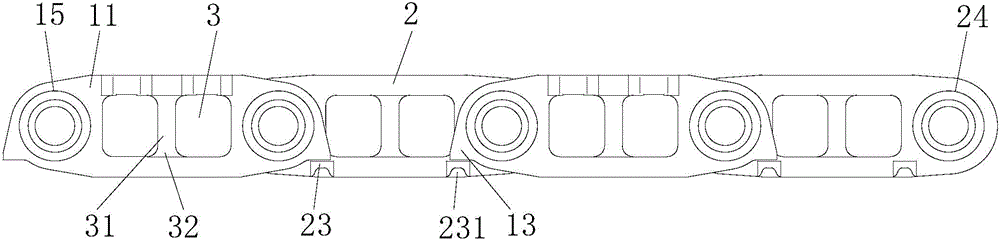

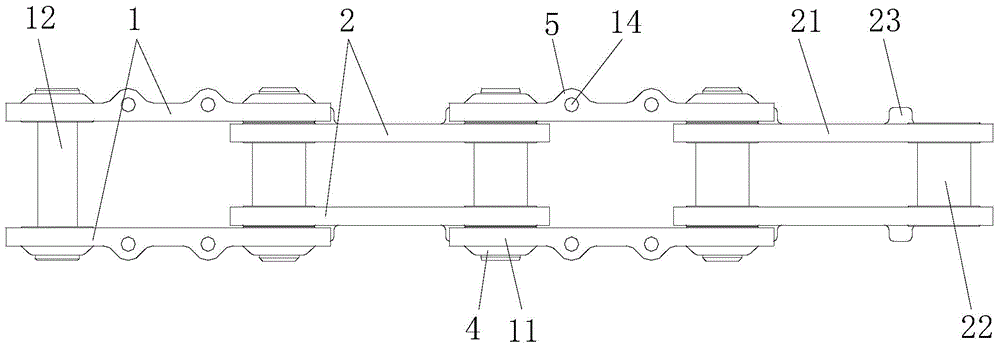

[0014] refer to figure 1 , figure 2 , the present invention is a one-way brake die forging chain on a clinker chain bucket conveyor, which includes a first chain segment 1 and a second chain segment 2, and the first chain segment 1 and the second chain segment 2 are connected alternately, each A second chain segment 2 is installed between two adjacent first chain segments 1, and the first chain segment 1 is composed of two first chain plates 11, and the two first chain plates 11 are connected by pin shafts 12. connection, both sides of the first chain plate 11 are provided with hook structures 13, the first chain plate 11 has a number of hopper installation holes 14, and the second chain segment 2 is composed of two second chain plates 21 , the two second chain plates 21 are connected through the bushing 22, the pin shaft 12 is installed in the bushing 22 to connect the first chain segment 1 and the second chain segment 2, both sides of the second chain plate 21 are provided...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com