Tool for hoisting steel inner barrel of chimney and application method of tool

A steel inner cylinder and chimney technology, applied in hoisting devices, hoisting devices, spring mechanisms, etc., can solve problems such as high cost and high safety risk, and achieve the effect of easy operation, low price and cost reduction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

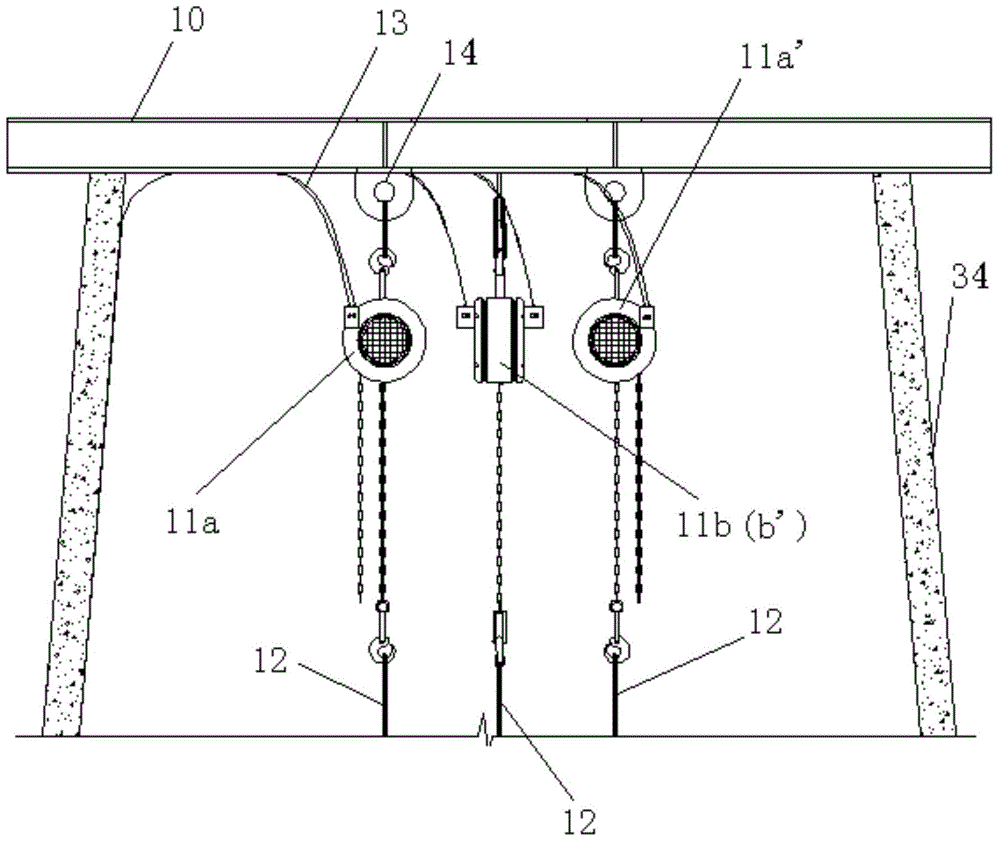

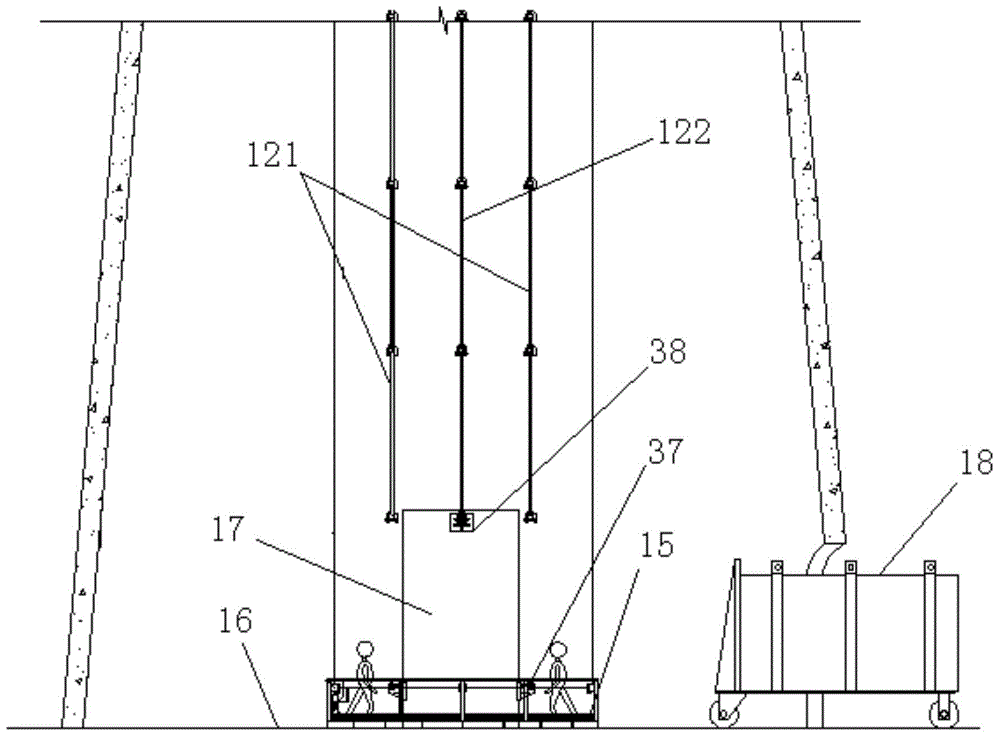

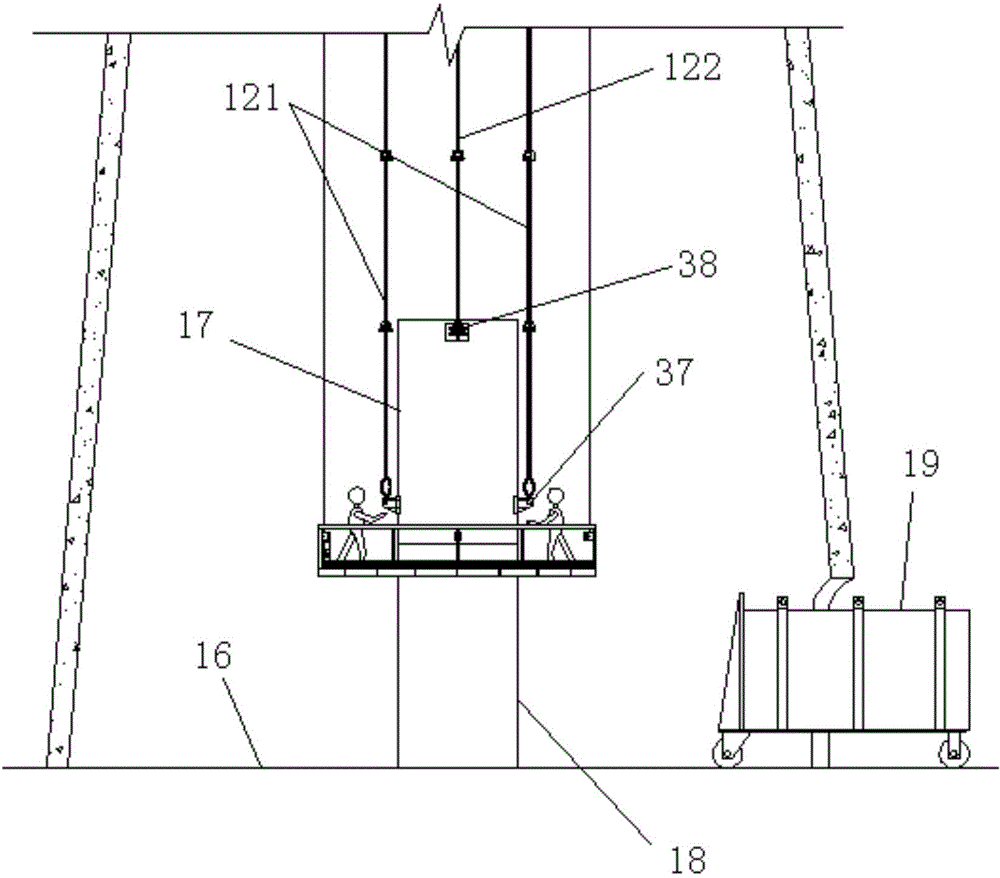

[0026] Combine below Figure 1-Figure 3 The tool of the present invention is introduced.

[0027] Such as figure 1 As shown, the tool of the present invention includes a suspension frame 10 and four electric hoists (three electric hoists are shown in the figure). The hoisting frame 10 is fixed on the top of the chimney 34; the lower surface of the hoisting frame 10 is provided with lifting lugs 14, and the electric hoists are installed on the lifting lugs 14; and the four electric hoists are evenly distributed on a circle whose diameter is equal to the outer diameter of the steel inner cylinder When the tool of the present invention is introduced below, two electric hoists located on one diameter of the above-mentioned circle are used as a group, and the four electric hoists are divided into two groups, group A and group B, and group A has two electric hoists 11a and 11a'; Group B has two electric hoists 11b and 11b'. The power cables and control cables 13 of the electric h...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com