A kind of preparation method of iodized oil with stable quality

A technology of stable quality and iodized oil, which is applied in the fields of fat oil/fat refining, active ingredients of iodine compounds, medical preparations containing active ingredients, etc., and can solve problems such as free iodine and color easily exceeding the standard

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

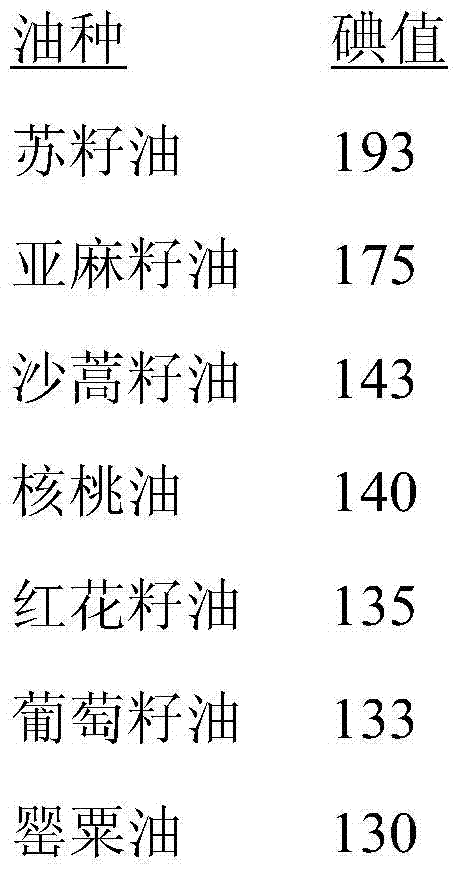

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0038] 300g perilla seed oil is cooled to -10°C at a rate of 1-2°C per hour in a low-temperature thermostat (purchased from Kerui Instrument Co., Ltd., Gongyi City, model: Kerui brand DFY-50 / 30). degrees (about 20 hours), and continue to maintain at -10 degrees Celsius ± 0.5 degrees for 24 hours. In the Buchner suction funnel, take advantage of cold suction filtration to obtain 292g of defatted and dewaxed perilla seed oil.

[0039] In the hydrogen iodide gas generator (purchased from Dezhou Fukai Chemical Co., Ltd., model: 1000ml Qipu generator), add red phosphorus 15g, iodine sheet 200g, continuously and slowly drop hydriodic acid 70g, the generated The hydrogen iodide gas is absorbed into 292g of degreasing dewaxed perilla seed oil under stirring, to obtain 483g of iodized oil. The yield (according to the average iodine content of 40%) is 96.6%, the iodine content is 39.6%, the free iodine is qualified, and the color is qualified.

[0040] After the accelerated stability ...

Embodiment 2

[0048] 300g walnut oil is cooled to 5 degrees centigrade at a rate of 1-2 degrees centigrade per hour in a low-temperature thermostat (purchased from Kerui Instrument Co., Ltd., Gongyi City, model: Kerui brand DFY-50 / 30). About 10 hours), continue to keep at 5 degrees Celsius ± 0.5 degrees for 24 hours. Take advantage of cold suction filtration in Buchner suction funnel to obtain 284g of degreasing and dewaxing walnut oil.

[0049] In the hydrogen iodide gas generator (purchased from Dezhou Fukai Chemical Co., Ltd., model: 1000ml Qipu generator), add red phosphorus 15g, iodine sheet 200g, continuously and slowly drop hydriodic acid 70g, the generated Hydrogen iodide gas is absorbed in the degreasing dewaxed walnut oil of 284g under stirring, obtains iodized oil 486g. The yield (according to the average iodine content of 40%) is 97.2%, the iodine content is 40.4%, the free iodine is qualified, and the color is qualified.

[0050] After the accelerated stability test at 54 deg...

Embodiment 3

[0055] With 300g grapeseed oil, in the low-temperature thermostat (purchased from Gongyi Kerui Instrument Co., Ltd., model: Kerui brand DFY-50 / 30), the temperature is lowered to -5°C at a rate of 1-2°C per hour. degrees (about 15 hours), and continue to maintain at -5 degrees Celsius ± 0.5 degrees for 24 hours. In the Buchner suction funnel, take advantage of cold suction filtration to obtain 287g of defatted and dewaxed grapeseed oil.

[0056] In the hydrogen iodide gas generator (purchased from Dezhou Fukai Chemical Co., Ltd., model: 1000ml Qipu generator), add red phosphorus 15g, iodine sheet 200g, continuously and slowly drop hydriodic acid 70g, the generated The hydrogen iodide gas is absorbed in the defatted dewaxed grapeseed oil of 287g under stirring, obtains 485g of iodized oil. The yield (according to the average iodine content of 40%) is 97.0%, the iodine content is 39.7%, the free iodine is qualified, and the color is qualified.

[0057] After the accelerated sta...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com