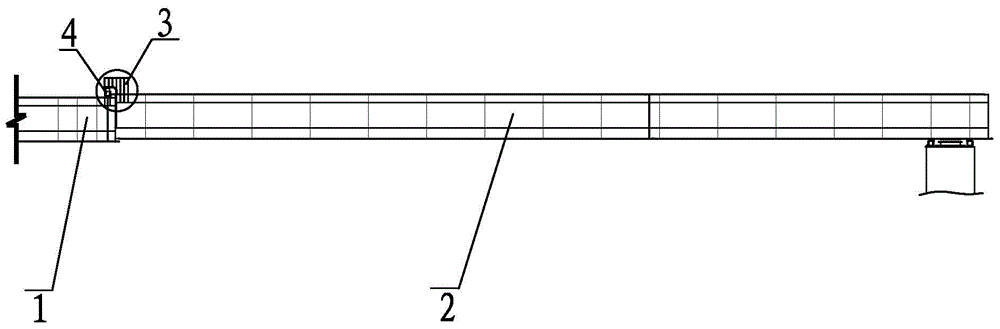

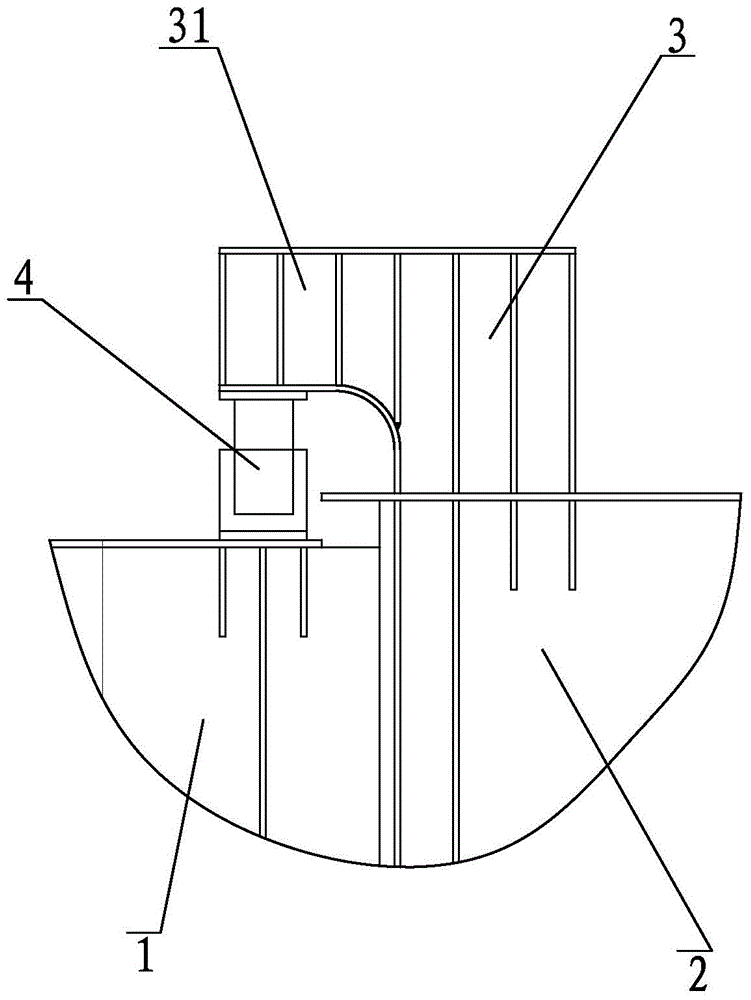

Steel box beam jacking pushing and slide moving construction method and beam falling auxiliary device

A construction method and technology of auxiliary devices, which are applied to bridges, bridge construction, erection/assembly of bridges, etc., can solve problems such as unfavorable adjustment of bridge alignment, large number of bridge pier supports, and difficulty in aligning multiple supports at the same time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0018] The invention discloses a steel box girder jacking and sliding construction method, including the following steps: 1), truncation mark identification; 2), reference segment installation; 3), pre-correction before the segment is in place; 4), Margin cutting; 5), segment fine adjustment; 6), beam bottom pad copying; 7), installation of beam drop auxiliary device; 8), drop beam positioning; 9), drop beam into a bridge.

[0019] The above steps are specifically expanded as follows:

[0020] The step 1) is specifically: after the steel box girder is assembled on the assembly platform, measure the camber, transverse slope, and external dimensions and report for inspection. Mark the punching points at both ends of the axis, and make clear marks with paint, as the reference point for measuring the position of the segmental beam.

[0021] The step 2) is specifically: starting from the 35# small pile end at the south end of the bridge, install the 35-37# span inner steel box gir...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com