A prefabricated balcony structure and its construction method

A balcony and balcony slab technology, applied in balconies, building components, building structures, etc., can solve the problems of large on-site construction volume, long construction period, slow progress, etc., and achieve the effects of short construction period, rapid construction, and safe construction.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0034] The technical scheme of the present invention will be described in detail below in conjunction with the accompanying drawings.

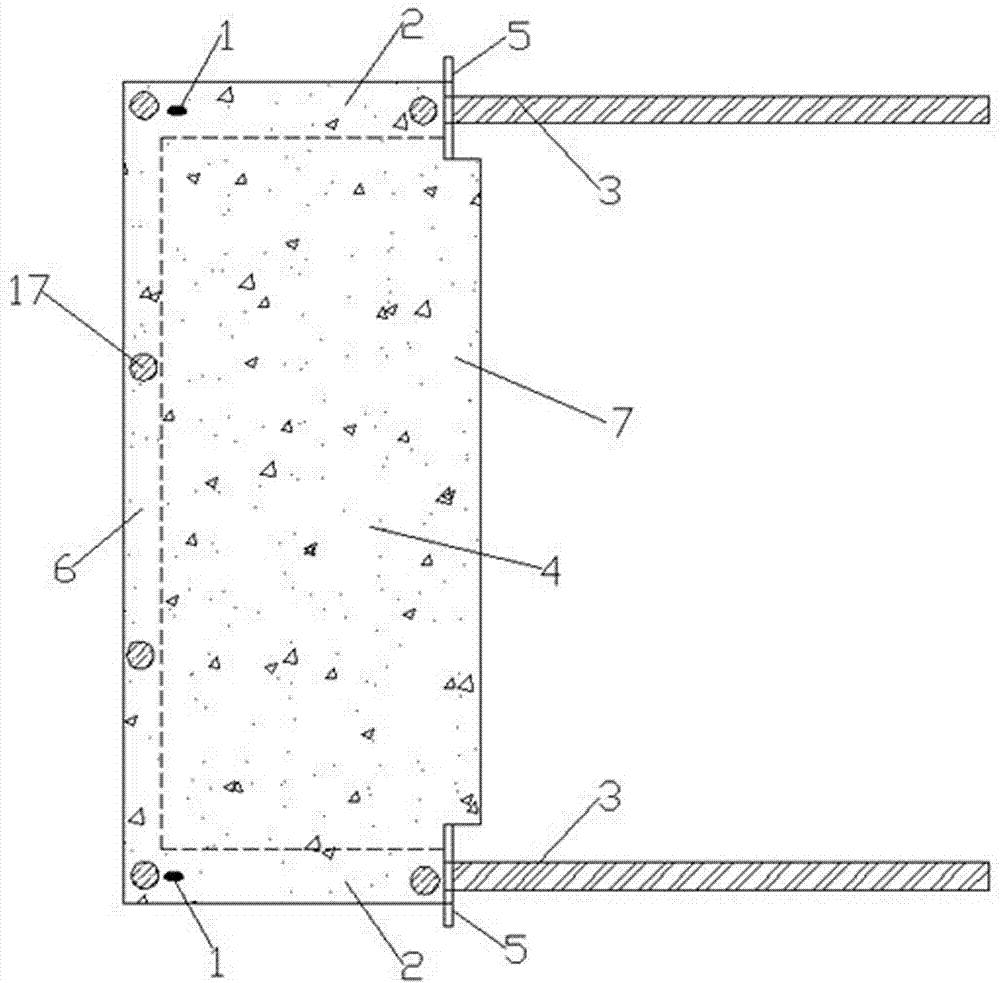

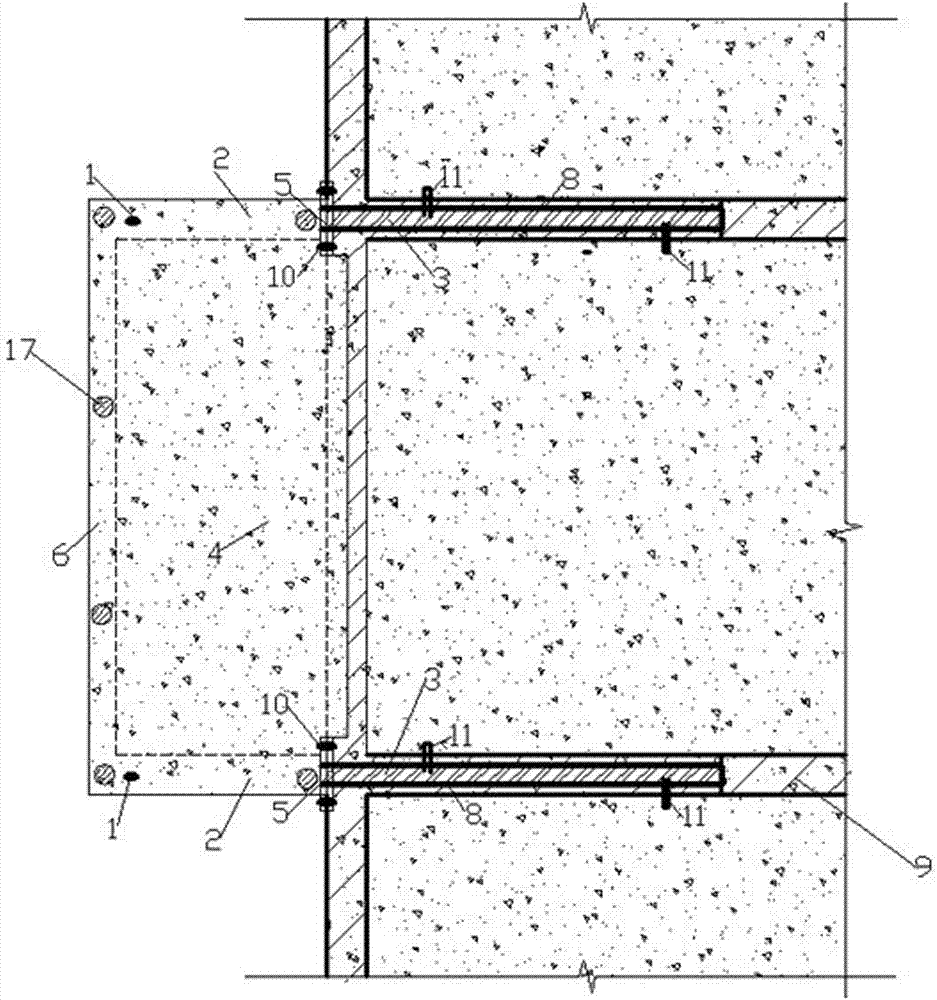

[0035] Such as figure 1 As shown, a prefabricated balcony structure of the present invention can be prefabricated in the factory, and can be transported to the construction site as an integral part of system integration and technical support, which can reduce the amount of on-site construction, make the construction simple and convenient, speed up the construction, Shorten the construction period.

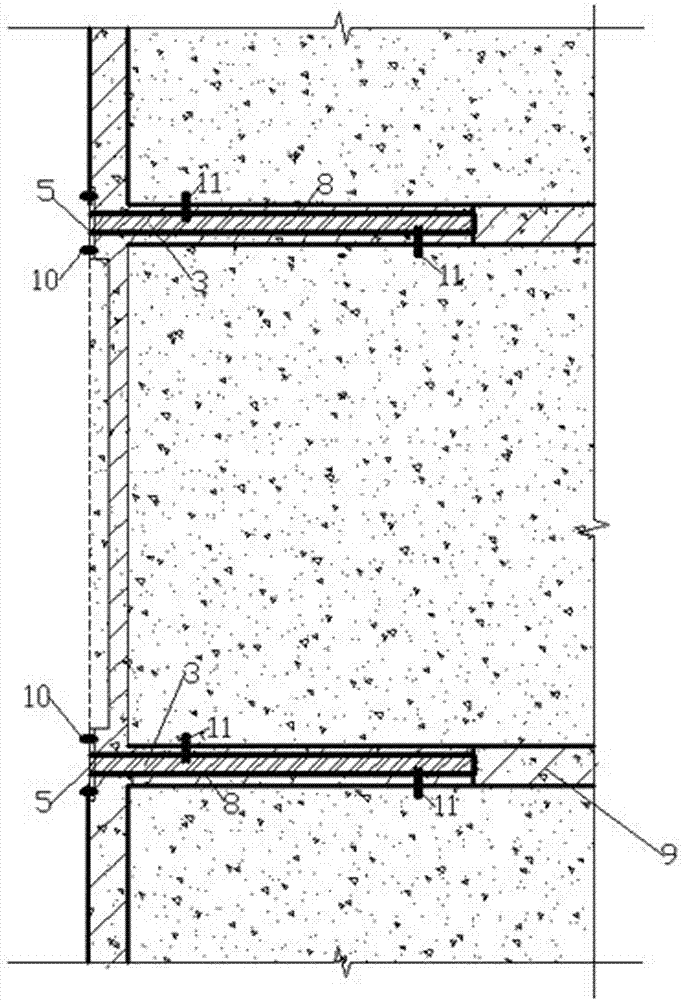

[0036] The main body of the prefabricated balcony includes a prefabricated balcony slab formed by pouring reinforced concrete, a cantilever beam 2 and a side beam 6, and the prefabricated balcony slab is integrated with the cantilever beam 2 and the side beam 6 on both sides. Cantilever beams 2 are arranged on the left and right sides of the prefabricated balcony slab, and embedded connectors 3 are arranged at the connecting ends of the cantileve...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com