Half-round head rivet

A half-round head and rivet technology, applied in rivets and other directions, can solve the problems of inconvenient assembly of half-round head rivets, scratching people, easy to scratch, etc., and achieve the effect of solving injuries to people and parts, eliminating impact, and avoiding stress concentration

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

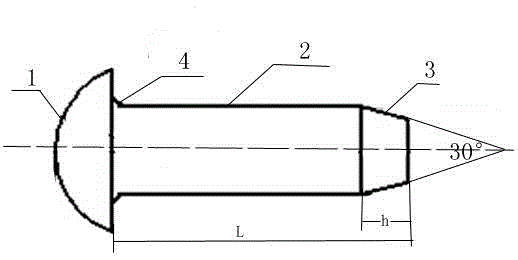

[0014] The present invention as figure 1 shown.

[0015] A half-round head rivet comprises a half-round head cap 1, a tie rod 2 is arranged under the half-round head cap 1, and a guide taper 3 is arranged at the front end of the tie rod 2.

[0016] The guide taper 3 is 30°.

[0017] An R arc 4 is provided at the junction of the cap 1 of the semicircular head and the tie rod 2, and the R dimension of the R arc 4 is 0.3-0.4 mm.

[0018] h is the length of the right-angled side of the taper, respectively:

[0019] L h

[0020] 8mm 3-4.5mm

[0021] 10mm 5.5-8mm

[0022] 12-16mm 6-8.5mm.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com