Dual-nut ball screw assembly with controllable pre-tightening force

A ball screw pair and pre-tightening nut technology, applied in the direction of transmission, belt/chain/gear, transmission parts, etc., can solve the problem of not being able to accurately reflect and adjust the size of the pre-tightening force, so as to improve accuracy retention and The effect of reliability, high dynamics

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

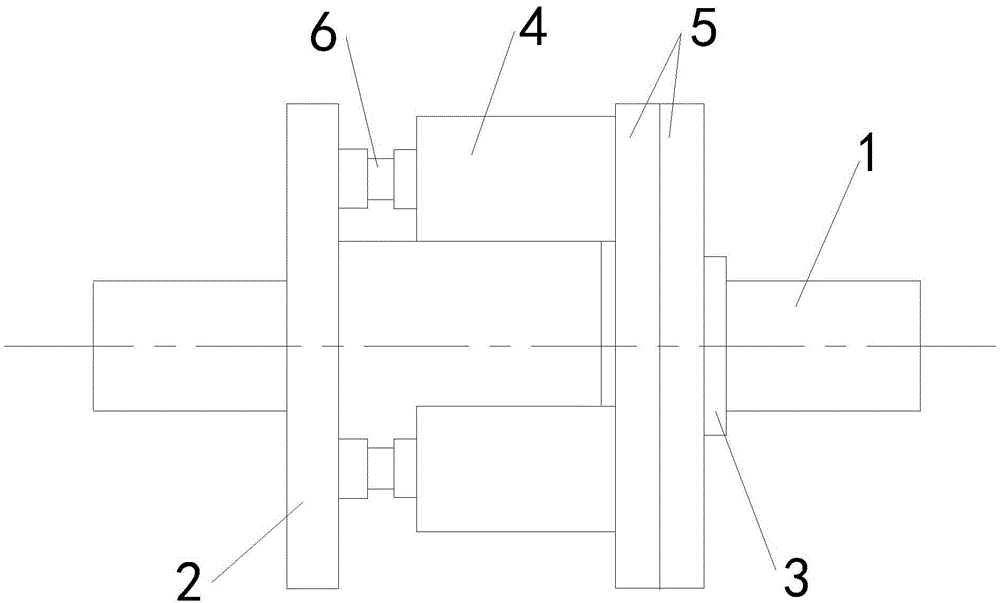

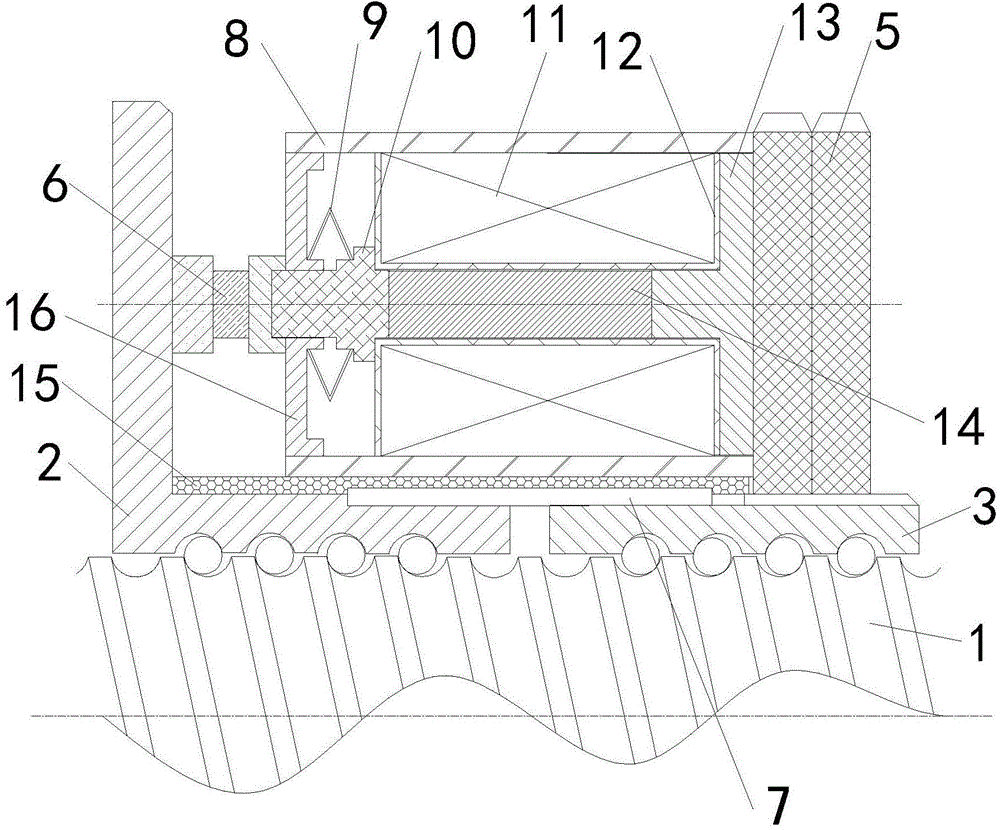

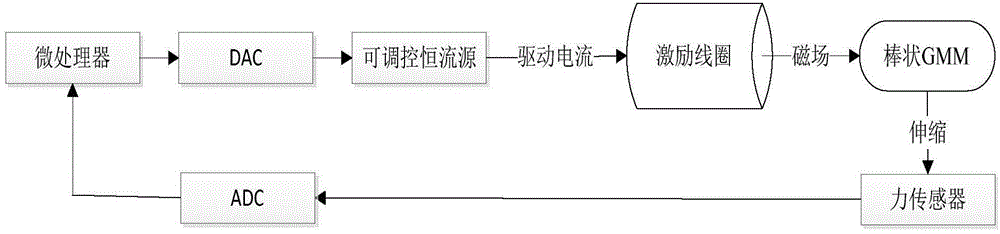

[0020] The double-nut ball screw pair with controllable pretightening force of the present invention, such as figure 1 As shown, it includes a lead screw 1 and two lead screw nuts (A lead screw nut 2 and B lead screw nut 3), both of which are connected to the lead screw. Wherein the B lead screw nut 3 is provided with two circular pre-tightening nuts 5 . A giant magnetostrictive actuator 4 ( figure 1 There are three in the middle, uniformly distributed at intervals of 120 °), a force sensor 6 is set between one end of each giant magnetostrictive actuator 4 and the A lead screw nut 2. The number of giant magnetostrictive actuators 4 can be determined according to the outer diameter of the lead screw 1 and the load it receives. The force sensor 6 adopts a piezoelectric force sensor to obtain the magnitude of the pretightening force in time. The pre-tightening nut 5 is connected to the B screw nut 3 and is used to set the initial pre-tightening force of the double-nut ball scr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com