Trenchless prop

A non-excavation, pipe jacking technology, applied in the direction of pipeline laying and maintenance, pipes/pipe joints/fittings, mechanical equipment, etc., which can solve the problem of small axial jacking force, reduced axial support force, and prone to bending To avoid torsion and other problems, achieve the effect of maintaining integrity and improving axial jacking force

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

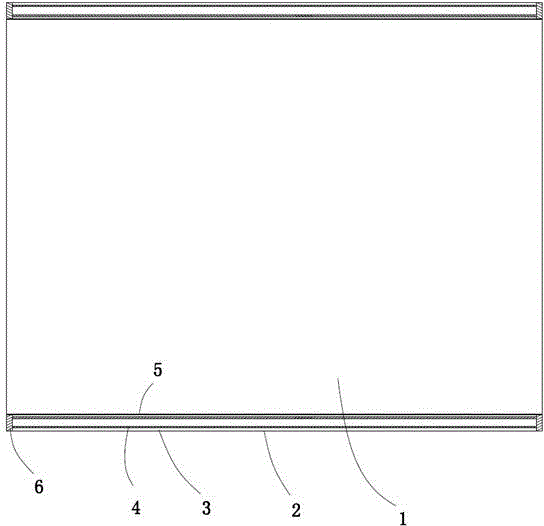

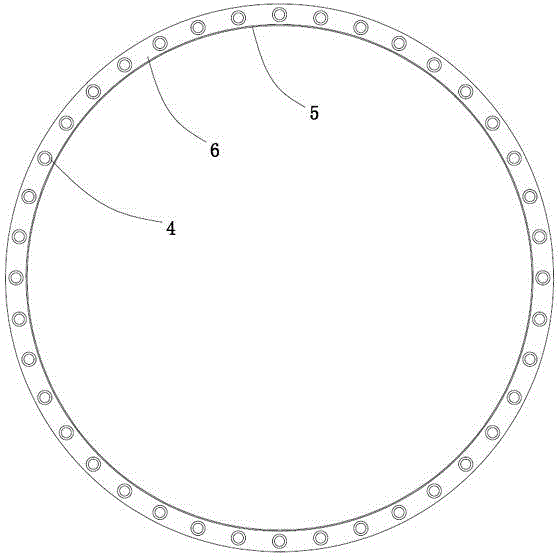

[0028] Embodiment 1: a kind of non-excavation pipe jacking (see attached figure 1 attached figure 2 attached image 3 ), the top pipe is circular, including the inner wall 5, the outer wall 2 and the filler 3 between the inner wall and the outer wall. The two ends of the pipe jacking are provided with closing plates 6, and a plurality of steel pipes 4 are connected between the closing plates, and the ends of the steel pipes are welded and fixed to the surface of the closing plates. The filler is filled outside the steel pipe, the axis of the steel pipe is parallel to the axis of the pipe jacking, and the steel pipes are evenly arranged in the wall of the pipe jacking.

[0029] The closing plate is annular, and the outer diameter of the closing plate is consistent with the outer diameter of the pipe jacking. The inner wall of the jacking pipe extends to the inner ring surface of the closing plate, the ends of the steel pipes are fixed to the closing plate, and the steel pip...

Embodiment 2

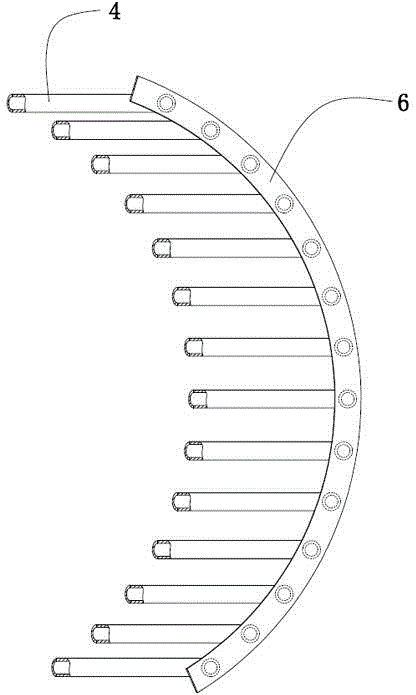

[0031] Embodiment 2: a kind of non-excavation pipe jacking (see attached Figure 4 ), the difference from Example 1 is that the steel pipe and the surface of the closed panel are welded and fixed, the steel pipe is arranged along the position where the pipe wall of the jacking pipe is deflected to the inner wall, and the appearance of the steel pipe is tangent to the inner arc edge of the closed plate. Refer to Example 1 for all the other structures.

Embodiment 3

[0032] Embodiment 3: a kind of non-excavation pipe jacking (see attached Figure 5 ), the closed plate at one end of the jacking pipe is formed by butting two semi-closed plates 7, the two semi-closed plates are symmetrical to each other, and the ends of the two semi-closed plates are butted and fixed to form a complete closed plate. The end of the steel pipe is fixed with the semi-closed plate to form a support frame, and the two support frames are combined to form an integral axial support frame for pipe jacking. Refer to Example 1 for all the other structures.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com