Illumination system having semiconductor light source module

A technology of lighting system and light source module, applied in the field of lighting system, can solve the problem of high cost of vehicle lamp module and the like

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0040] In order to make the structural features of the present invention and the achieved effects have a further understanding and recognition, preferred embodiments and detailed descriptions are specially used, which are described as follows:

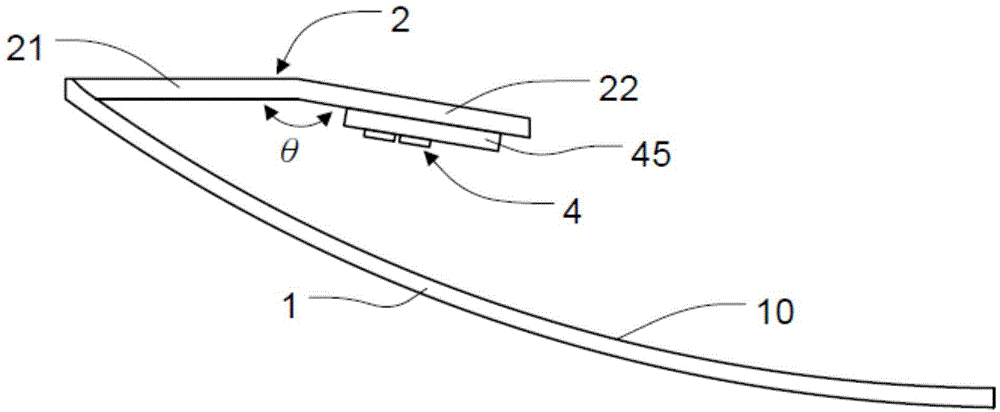

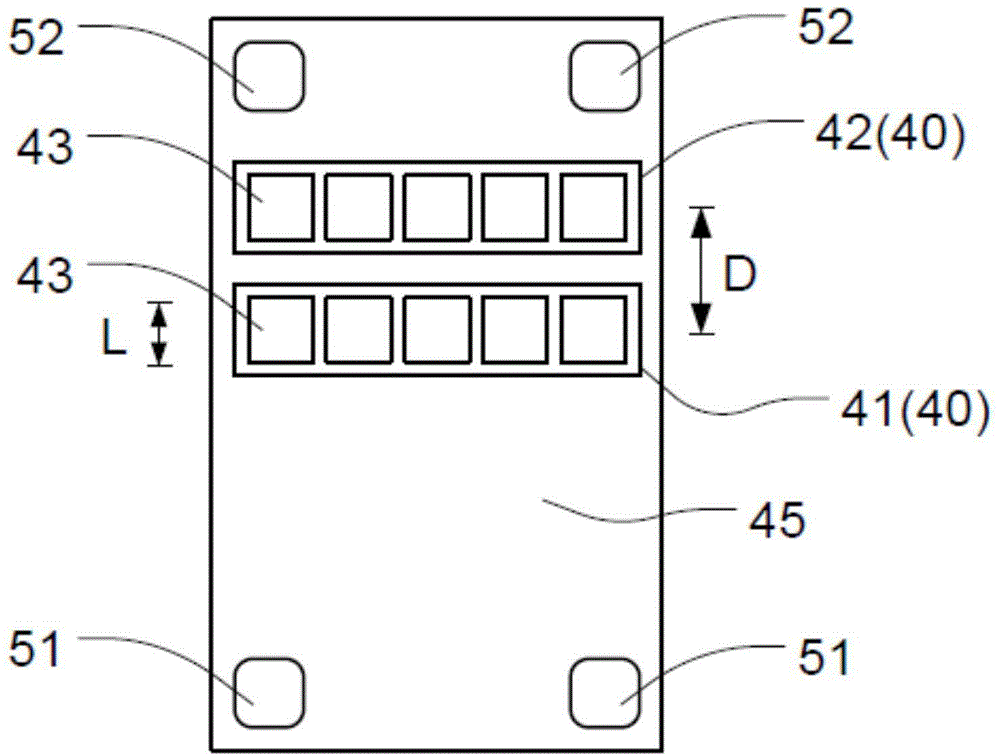

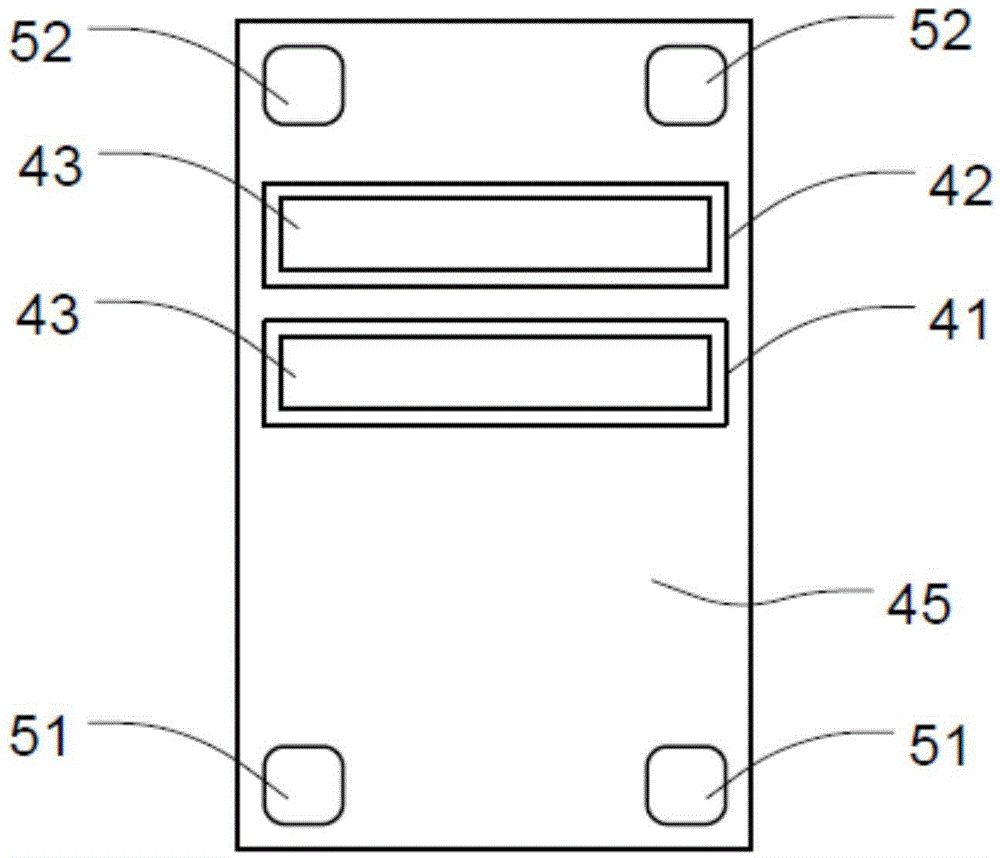

[0041] First, please refer to figure 1 , an embodiment of the present invention structurally includes: a reflector 1 , a bracket 2 and a semiconductor light source module 4 . Wherein, the side of the reflector 1 having a reflective function is a reflective arc surface 10, and the reflective arc surface 10 is a reflective surface having at least one curvature; the bracket 2 is coupled to the reflector 1, And includes a first bracket part 21 and a second bracket part 22, the first bracket part 21 is arranged between the reflector 1 and the second bracket part 22; the semiconductor light source module 4 is arranged on the The second bracket portion 22 is facing the reflective curved surface 10 . There is a turning point between at least...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com