High frequency high voltage transformer module

A transformer module, high-frequency and high-voltage technology, applied in the direction of transformer/inductor magnetic core, transformer/inductor parts, transformer/inductor coil/winding/connection, etc., can solve the problem of affecting power supply miniaturization and compact structure design , silicon stack and capacitor volume increase, voltage and current waveform distortion, etc., to achieve the effect of improving energy transmission efficiency, improving coupling coefficient, and small distributed capacitance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

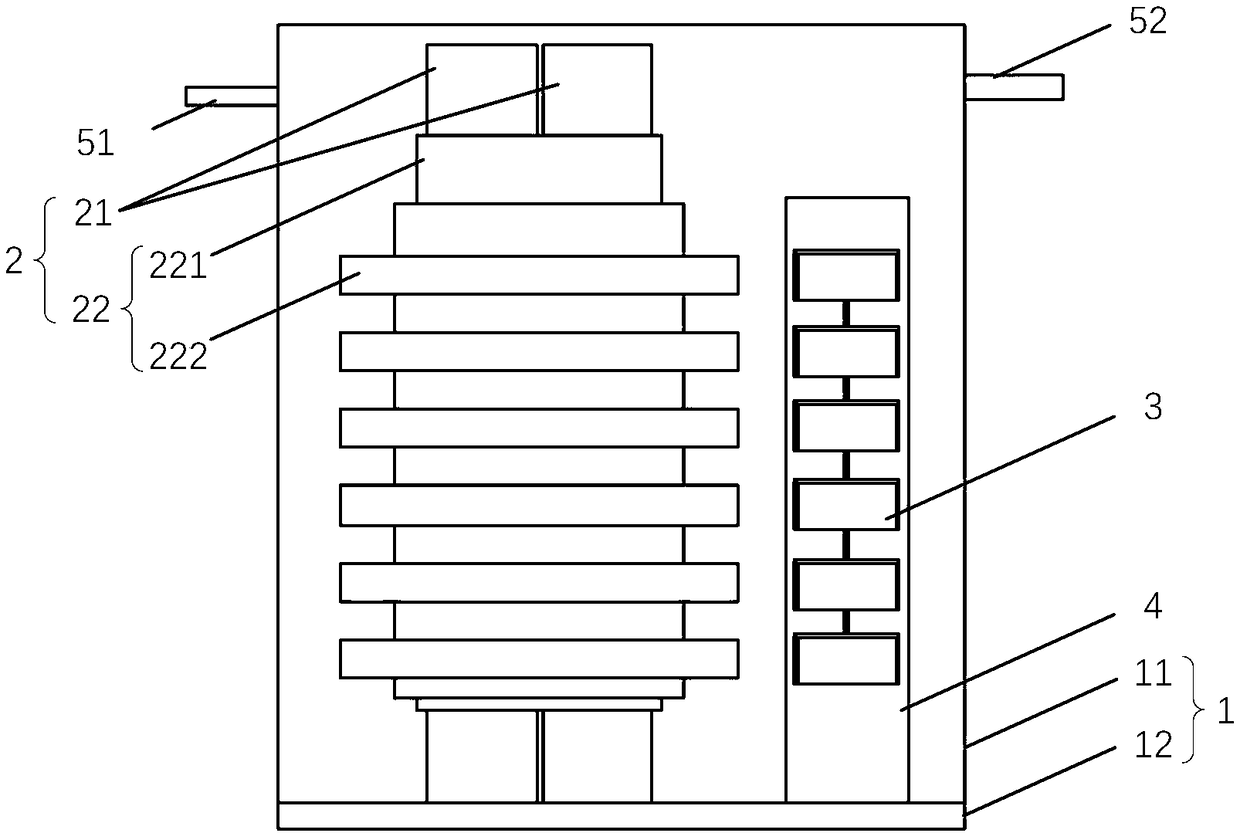

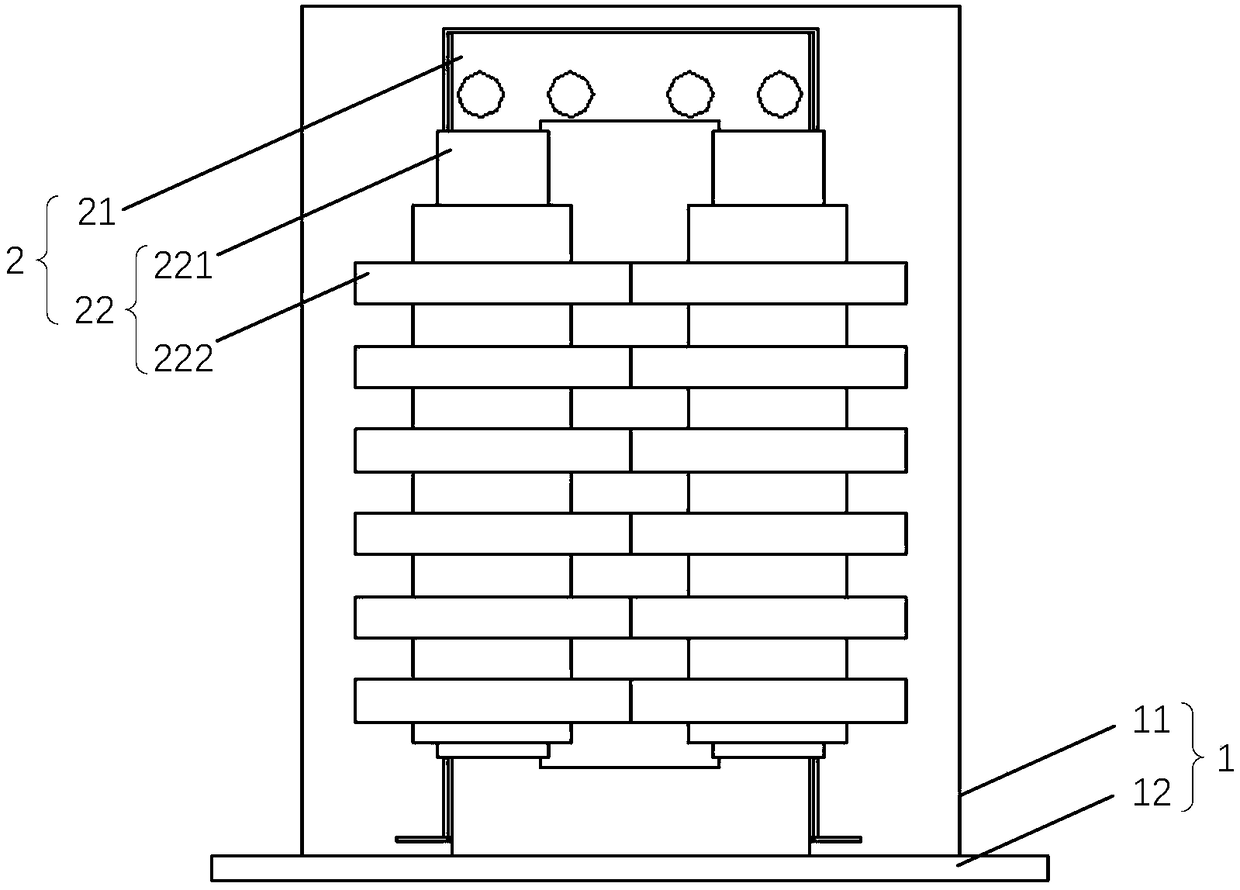

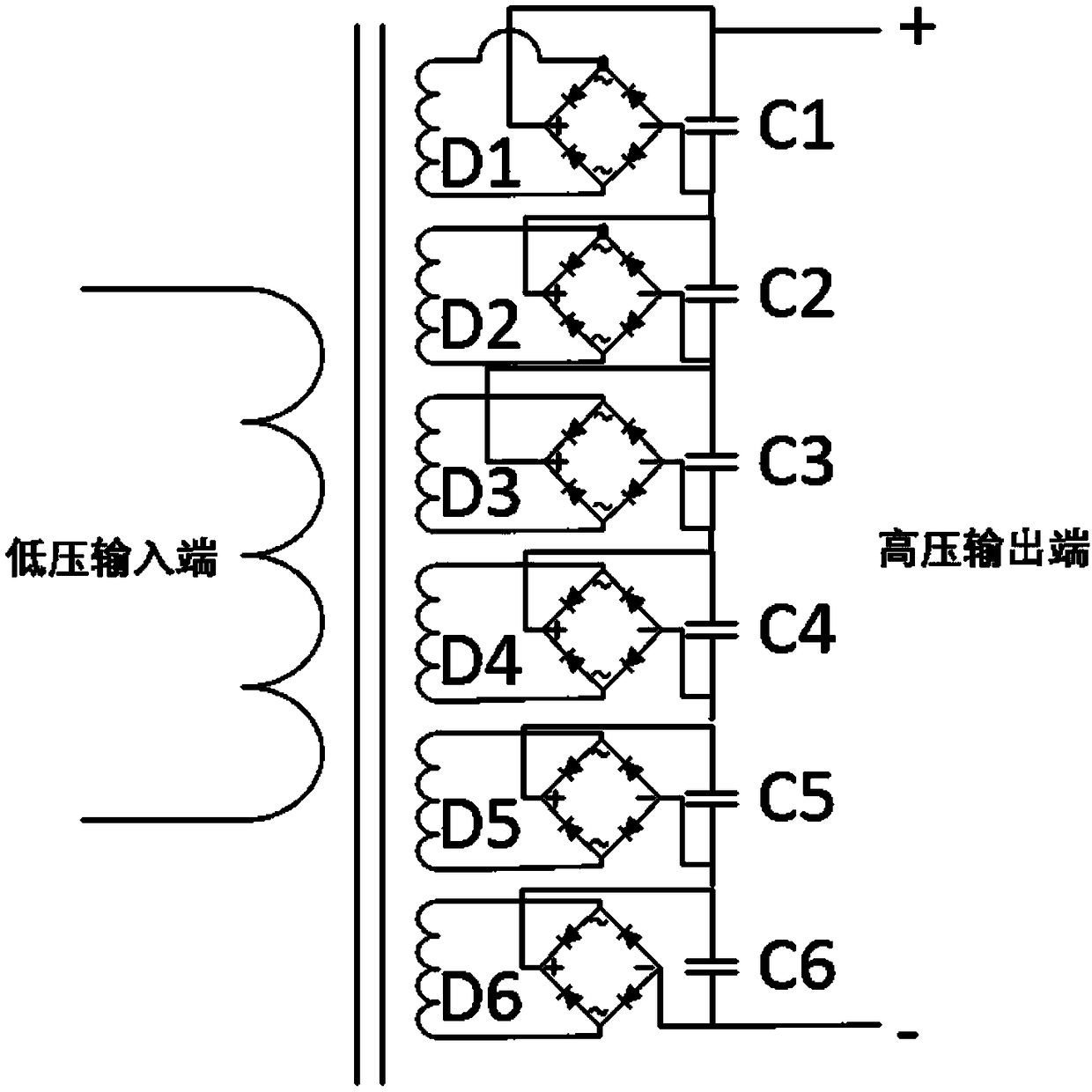

[0030] A high-frequency high-voltage transformer module, such as Figure 1-2 As shown, it includes: a transformer 2 and a rectifier filter 3; the transformer 2 includes: a U-shaped magnetic core 21, a transformer bobbin 22, a primary winding and a secondary winding; the transformer bobbin 22 includes: two hollow inner bobbins 221 and two outer skeletons 222; the two inner skeletons 221 wrap the two vertical parts of the U-shaped magnetic core 21 respectively; the two outer skeletons 222 respectively wrap the two inner skeletons 221; the two inner skeletons 221 are wound with primary Winding; the two outer frames 222 are respectively wound with secondary windings; the secondary windings are connected to the rectifier filter 3 . Preferably, the high-frequency high-voltage transformer module includes: two identical U-shaped magnetic cores 21; the sides of the two U-shaped magnetic cores 21 are closely overlapped, so that the window area is large, so that the area of the winding...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com