Energy-saving control method for discharge furnace door of heat-accumulating heating furnace

A heating furnace and regenerative technology, which is applied to furnace control devices, lighting and heating equipment, furnaces, etc., can solve the problems of heat overflow in the furnace and high consumption of gas inhaled by cold air outside the furnace, and achieves reduction of heat loss and complete furnace door. The effect of saving opening time and shortening tapping time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

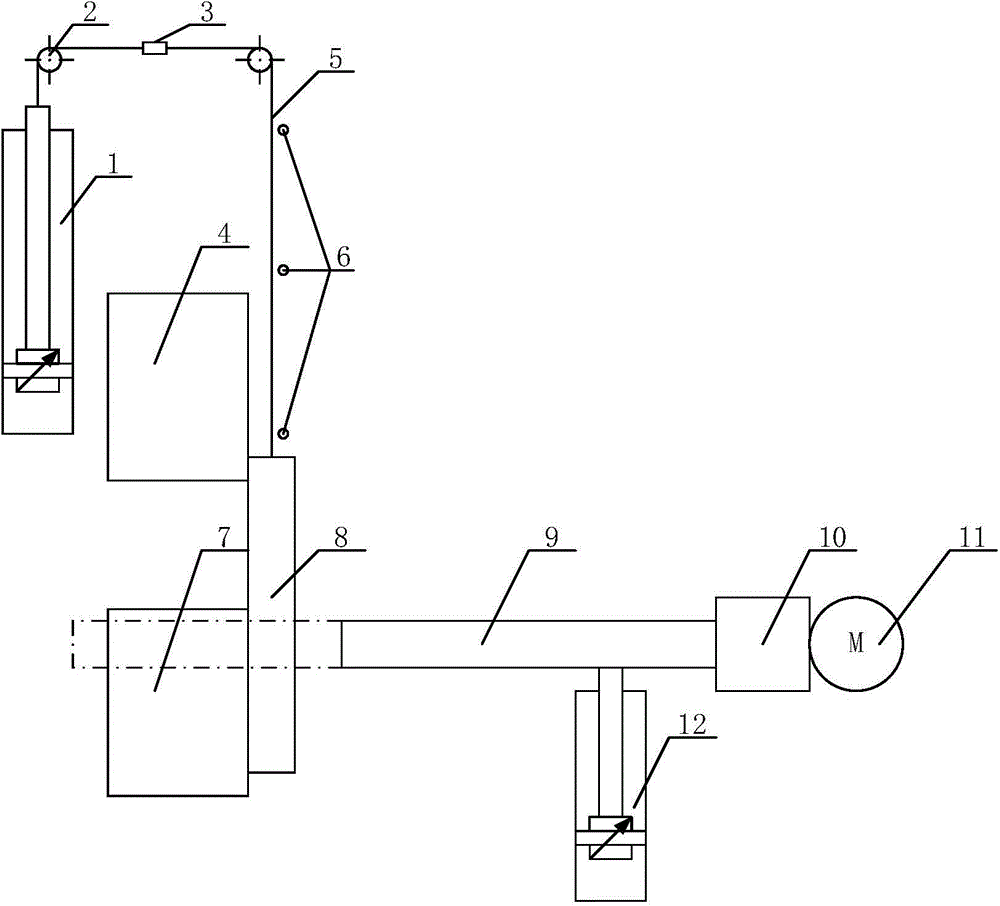

[0018] The steps of the energy-saving control method for the discharge furnace door of the regenerative heating furnace are as follows:

[0019] 1. Add a furnace door position detection device 6 to the chain 5, and connect the signal to the control PLC. The furnace door position detection device 6 is a proximity switch.

[0020] 2. The heating furnace receives the automatic tapping signal, and the furnace door 8 starts to lift. When the furnace door position detection device 6 detects that the furnace door 8 reaches the middle opening position, the furnace door 8 stops and is in a half-open state. At this time, the furnace door The door 8 is lifted above the lower end wall 7 of the discharge end to ensure that the tapping machine support arm 9 can move forward normally, and at this moment, the furnace door 8 is in a continuous closed state to the discharge end.

[0021] 3. The supporting arm 9 of the tapping machine advances under the drag of the motor 11 after the speed chan...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com